Making And Laying Concrete. Continued

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol2: Masonry. Carpentry. Joinery", by The Colliery Engineer Co. Also available from Amazon: A Treatise On Architecture And Building Construction.

Making And Laying Concrete. Continued

132. Expansion And Contraction

Expansion And Contraction. When concrete sets in air it contracts slightly, but often sufficiently to produce cracks in the walls and floors. To prevent this, it is customary to employ some means to allow for expansion and contraction. The usual method is to make false joints in the work, which the cracks will follow, and will not appear on the face of the wall.

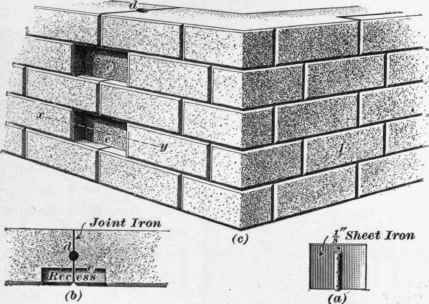

A method of accomplishing this object is represented in Fig. 67. A 1/8-inch iron plate, usually the height of a course of concrete, is shown in plan at a, in (b), which is a cross-section on line x y in (c); a front view of the jointer is shown in (a). The plate is set upright, in line with one of the vertical strips which form the false joints, and the concrete is laid on both sides of it; when the latter has set, the plate is pulled up, leaving an open joint through the wall, as seen at d in (c). Wherever these are made, spaces are left in the face of the blocks above and below, as shown at e in (b) and (c). Such joints permit the concrete to contract and settle without defacing the wall. When these actions have ceased, the recesses are filled with closely fitting-blocks, laid in strong mortar. At f is shown a block, or plate, inserted, which, when properly put in, is undistinguishable from the rest of the work. This plan has been found very effective in preventing the appearance of disFiguring cracks on the exterior of the walls.

Fig. 67.

In placing band courses, trimmings, etc., much care must be taken to have them so arranged that shrinkage in the concrete will not injure them. All window sills should be slip sills, so that, if the wall settles, the ends of the sills will remain unbroken. For similar reasons, it is well to have the window lintels made in the form of a flat arch with a through joint at the center, and a recess for a key, which is put in later.

133. Surface Finish

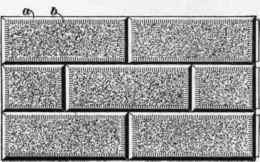

Surface Finish. Up to within a few years, the outside covering of most of the concrete buildings was plaster or mortar; this finish, however, does not prove satisfactory, and increases the cost considerably. It is now customary to cut the outside faces of concrete walls to closely resemble rough-dressed stonework. Since concrete is artificial stone, some form of finish is as necssary for it as for natural stonework. The effect of coursed stone or ashlar is produced by forming imitation joints in the face of the wall, as shown in Fig. 68, and afterwards either picking or tooling the surface. In imitating rough - dressed work, the crib, or mold, is taken from the concrete wall before it becomes absolutely hard, and the finishing may then be done very rapidly. When an imitation of finer tooled work is desired, the concrete should be allowed to harden for a longer period before being cut.

Fig. 68 represents a method of finishing the face of concrete blocks; a shows the joint in the concrete; b, a margin, or draft, cut to imitate tooled work; and c, the picked face. If the strips which form the apparent joints have been properly planed and beveled, the recessed joints should need no dressing.

Fig. 68.

Continue to: