56. Square Or Rectangular Leaders

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol3: Stair Building, Ornamental Ironwork, Roofing, Sheet-Metal Work, Electric-Light Wiring And Bellwork", by The Colliery Engineer Co.. Also available from Amazon: A Treatise On Architecture And Building Construction.

56. Square Or Rectangular Leaders

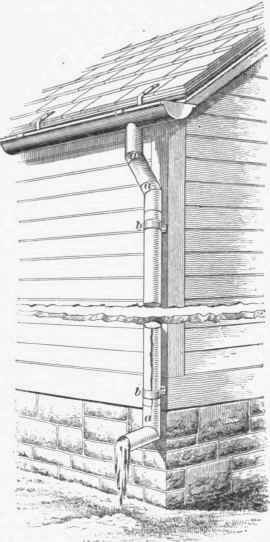

These leaders are made of crimped or corrugated sheet metal, and are often used to obtain a more ornamental effect than is produced by round leaders. They should be supported by ornamental bands in a manner very similar to the plain straps shown in Fig. 43, the straps being made so that the leaders will hug the wall. If the walls are built of masonry or brickwork, it is necessary to drill holes at the back of the bands, then drive soft-pine plugs into the holes and cut them flush with the face of the wall for the purpose of receiving the spikes; for good work expansion bolts should be used.

Fig. 43.

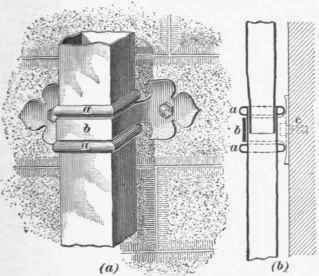

In climates where there is no danger of outside leaders being frozen, the best method of attaching rectangular leaders in a neat and strong manner to brick, stone, or terra-cotta walls, is shown in elevation at (a) and in section at (b), Fig. 45. Two copper beads a, a are soldered around the top edge of each leader and a cast-copper band b, provided with ornamental lugs, clasps the top of the leader against the building. The lugs are secured to the walls with expansion bolts, as shown by dotted lines at c. The leaders are connected together by slip joints as shown in the section. Each band thus supports a section of the leader, which should not exceed 8 feet in length. This arrangement allows each section to expand and contract freely; if all the joints are soldered together, the leader is formed into one long, rigid line, which soon becomes loosened by expansion and contraction. These leaders should be made with the crimps running across them, not lengthwise, so as to secure a very neat, flat, and stiff surface.

Fig. 44.

Fig. 45.

Beaded tops and cast bands are not adapted for outside leaders in cold climates, because the beads and the bands are not pliable enough to resist the action of frost. The best attachment for such climates is composed of a brass or copper eye, which is riveted and soldered securely to the back of the top end of each section of the leader. These eyes are bolted to bronze hooks which are secured to the wall. An ornamental stamped sheet-copper band is then slipped on between the heads to conceal the real rigid attachment. The lugs of the band should be attached to the wall by expansion bolts. This arrangement gives a pliable joint. The corrugations in this leader, however, must run lengthwise, and all the joints should be slip joints. Iron supports should never be used in or against a stone wall, because they rust and stain the masonry.

57. Offsets in leaders should always be avoided. It is common practice to offset the leaders at stone, brick, and terra-cotta moldings, but in good practice they should be fitted up straight and plumb, the necessary holes being cut through special blocks formed in the molded courses for the passage of the leaders. It is customary to discharge sheet-metal leaders into a cast-iron pipe which is continued up about 4 or 5 feet above the surface of the ground, the object being to prevent the leader from being flattened or otherwise injured. Rectangular leaders should, for the sake of appearance, connect at the bottom with a rectangular cast-iron pipe, and not with a round pipe.

Continue to: