66. Horizontal Seams

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol3: Stair Building, Ornamental Ironwork, Roofing, Sheet-Metal Work, Electric-Light Wiring And Bellwork", by The Colliery Engineer Co.. Also available from Amazon: A Treatise On Architecture And Building Construction.

66. Horizontal Seams

The best form of horizontal seam that can be made on domes is shown in Fig. 49. A strong cold-rolled copper cleat strip a is nailed to the roof with flat-head brass or copper nails; and the top edge of the under sheet, the bottom edge of the upper sheet, and the cleat strip are all locked together as shown. With this arrangement, each sheet can expand and contract lengthwise without affecting the stability of the support. If the sheets are simply lapped at this seam, the wind will get underneath and raise them in the middle, thus opening the scams and making them visible from the street.

Fig. 49.

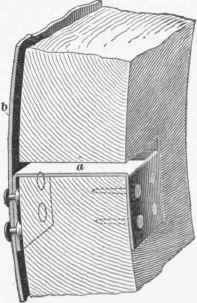

Fig. 50.

When it is required to set the rolls more than 2 feet apart, it becomes necessary to support the sheets between the rolls. This is accomplished in different ways. The sheets may be laid so that the horizontal locked seams will be about 18 or 20 inches apart, the rolls being perhaps 4 or 5 feet apart. When very large sheets must be used, however, secret tacks a, Fig. 50, are riveted and soldered to the back of the sheet b at intervals, which will allow about 2 or 3 square feet to be supported by each tack. As the sheets are being put on, the tacks are pushed into long, narrow holes in the woodwork, and then pulled through and nailed to the inside of the dome as shown.

Continue to: