156. Joining The Work

Description

This section is from the book "Building Construction And Superintendence", by F. E. Kidder. Also available from Amazon: Building Construction And Superintendence.

156. Joining The Work

A very important requirement of interior finish is that the joints shall be as tight and inconspicuous as possible, and, in fact, it was in the character of the joints and in the smooth surfaces and the smaller dimensions of the pieces that the distinction between joinery and carpentry arose.

The various joints made in connecting interior finish and fittings may be classified under one or more of the following kinds, viz.: butt joints, tongue and grooved joints, splined joints, mitred joints, coped joints, covered or housed joints, glued and blocked joints, and dovetailing, and the work is said to be butted, matched, mitred, coped, housed or rebated, glued and blocked, or dovetailed, according to the kind of joint that is made. Very frequently two of these operations are combined in a single joint.

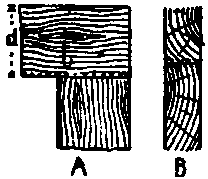

Butt Joints. - A butt joint is made by simply butting one piece against the other, as at A and B, Fig. 199. This is the easiest joint to make, but is objectionable, particularly in varnished work, in that any shrinkage in the board b, or in either or both of the boards at B, will cause the joint to open, as shown by dotted lines, and of course the greater the width or thickness d, or the wider the boards in B, the greater will be the shrinkage. Another objection to this joint is that ft is difficult to keep the surfaces joined in exactly the same plane, also when casings are joined, as at A, the end wood is exposed on the side, although the last objection can be overcome by placing a back band around the outer edge of the casings.

The principal instances in which butt joints are used in interior finishing are in joining plain or O. G. window casings, and where block and pilaster finish is used. (See Figs. 234 and 237). The butt joint is also used in flooring.

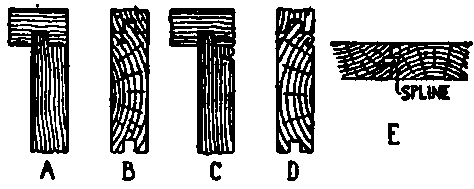

Tongued and Grooved Joint. - This is a form of butt joint in which one surface or edge is grooved, while the other has a tongue worked on it to fit into the groove, as shown at A and B, Fig. 200. The object of the tongue and groove is to keep the surfaces joined flush with each other, and also when the end is tongued it prevents the board from warping; in case of shrinkage the tongue also prevents dust from passing through, but it does not prevent the appearance of an open joint. To overcome the bad effect produced by shrinkage, a bead is often worked next to the tongue, as in C and D, the joint then having the same appearance as the quirk on the other side of the bead, unless the shrinkage is very great Boards tongued and grooved, as at B, are called "matched" boards, and when beaded are called matched and beaded : if there are two beads it is " double beaded," and if there is a bead at the centre it is "centre beaded." The tongue and groove is extensively used on flooring and sometimes on sheathing, while the matched and beaded joint should be used for ceiling.

Fig. 199 - Butt Joints.

Fig. 200. - Tongued and Groove Joints.

A splined joint is practically the same as a tongued and grooved joint, except that both edges are grooved, and the tongue or " spline," as it is called, is made of a separate piece, as at E. Splined joints are not as frequently used as the tongue and groove ; in joining very thick stuff, as 3 or 4-inch planking, the spline is more economical of material, and in making a very fine joint it is superior to the tongue and groove.

Continue to: