Cisterns And Tanks

Description

This section is from the book "Cyclopedia Of Architecture, Carpentry, And Building", by James C. et al. Also available from Amazon: Cyclopedia Of Architecture, Carpentry And Building.

Cisterns And Tanks

Water cisterns and tanks are made of various materials and in different shapes and sizes, according to the special uses for which they are required. A durable and satisfactory tank may be made of heavy woodwork or plank bolted together with iron rods and nuts and then lined with some sheet metal, such as copper, lead or zinc. Copper or lead makes the best lining, as the zinc has a greater tendency to corrode and become leaky. If copper is used, it should be tinned on the outside. Fig. 5 shows a wooden tank in plan, with the method of locking the joints in the copper lining. All nails should be so placed as to be covered by the copper, and the joints soldered with the best quality of solder, which should be allowed to soak into the seams. If the tank is lined with lead, a good weight should be used (about six pounds per square foot) and the joints carefully wiped by an experienced workman. If used for the storage of drinking water, this form of lining is open to the same objections as lead pipe, but if kept filled at all times, and especially if the water contains mineral matter to any extent, there is very little danger, as a coating is soon formed over the surface of the lead, protecting it from the action of the water.

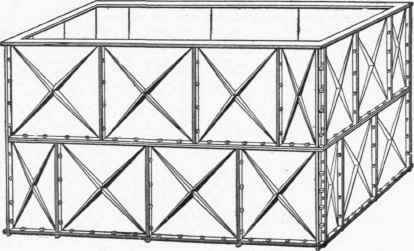

Fig. 6.

Cast-iron sectional tanks can be had in almost any size or shape. A tank of this form is shown in Fig. 6. It is made up of plates which are planed and bolted together, the joints being made tight with cement. The sections are made in convenient sizes, so that they may be handled easily and conveyed without difficulty through small openings to any part of the house. These tanks are easily set up, and are practically indestructible. Wrought= iron tanks are often used, but are not as easily handled as either of the kinds just described. Table VI will be found useful in computing the size of cylindrical tanks.

Continue to: