Form Of Heating Surface

Description

This section is from the book "Cyclopedia Of Architecture, Carpentry, And Building", by James C. et al. Also available from Amazon: Cyclopedia Of Architecture, Carpentry And Building.

Form Of Heating Surface

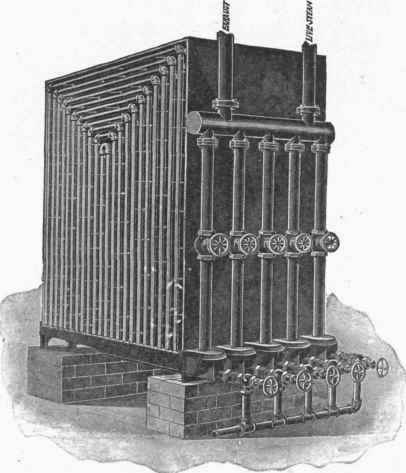

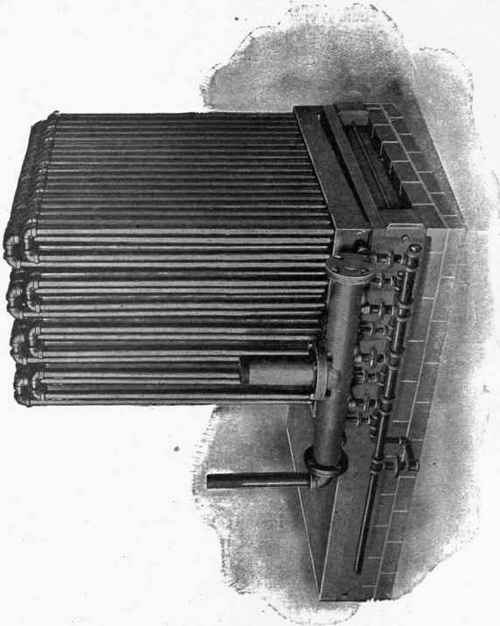

A common form of heater for forced blast heating is shown in Fig. 16, Part I. This consists of sectional cast-iron bases with loops of wrought-iron pipe connected as shown. The steam enters the upper part of the bases or headers and passes up one side of the loops, then across the top and down on the other side where the condensation is taken off through the return drip, which is separated from the inlet by a partition. These heaters are made up in sections of 2 and 4 rows of pipes each. The height varies from 3 1/2 to 9 feet and the width from 3 feet to 7 feet in the standard sizes. They are usually made up of 1-inch pipe although 1 1/4 inch is commonly used in the larger sizes. In Fig. 7 is shown a similar heater. This is arranged for supplying exhaust to a portion of the sections and live steam to the remainder. The division between the two sections is shown where the metal is broken away. Fig. 8 shows still another form; in this case all of the loops are made of practically the same length by the special form of construction shown. This is claimed to prevent the short circuiting of steam through the shorter loops which causes the outer pipes to remain cold.

Fig. 7.

Fig. 8.

Fig. 9.

This form of heater is usually encased in a sheet steel housing as shown, but may be supported on a foundation between brick walls if desired.

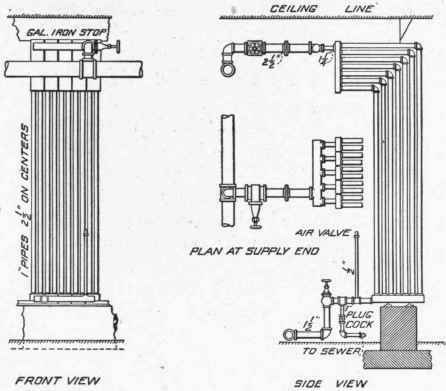

Fig. 9 shows a special form of heater particularly adapted to ventilating work where the air does not have to be raised above

70 or 80 degrees. It is made up of 1-inch wrought-iron pipe connected with supply and return headers: each section contains 14 pipes and they are usually made up in groups of 5 sections each. These coils are supported upon tee irons resting upon a brick foundation. Heaters of this form are usually made to extend across the side of a room with brick walls at the sides instead of being encased in steel housings. Heaters made up of banks of the school-pin cast-iron radiators give excellent results for schoolhouse work. The sections should be so arranged that the free area for air flow shall not be too much restricted.

Continue to: