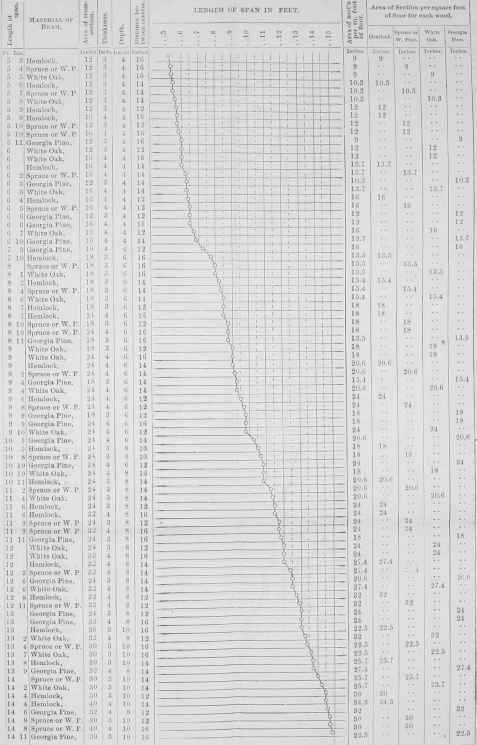

XII. Coor-Beams Per Square Foot Of Floor

Description

This section is from the book "Safe Building", by Louis De Coppet Berg. Also available from Amazon: Code Check: An Illustrated Guide to Building a Safe House.

XII. Coor-Beams Per Square Foot Of Floor

F SPAN IN FEET. | Area of seet'n per sq. foot of floor. | Area of Section per square foot of floor for each wood. | ||||||||

. .10 | . .11 | . .12 | . .13 | . .14 | . .15 | Hemlock | Sprue or W. Pine. | White Oak. | Georgia Pine. | |

Inches. | Inches. | Inches. | Inches. | Inches. | ||||||

9 | 9 | ... | ... | ... | ||||||

9 | ... | 9 | ... | ... | ||||||

9 | ... | ... | 9 | ... | ||||||

10.3 | 10.3 | ... | ... | ... | ||||||

10.3 | ... | 10.3 | ... | ... | ||||||

10.3 | ... | ... | 10.3 | ... | ||||||

12 | 12 | ... | ... | ... | ||||||

12 | 12 | ... | ... | ... | ||||||

12 | ... | 12 | ... | ... | ||||||

12 | ... | 12 | ... | ... | ||||||

9 | ... | ... | ... | ... | ||||||

12 | ... | ... | 12 | ... | ||||||

12 | ... | ... | 12 | ... | ||||||

13.7 | 13.7 | ... | ... | ... | ||||||

13.7 | ... | 13.7 | ... | ... | ||||||

10.3 | ... | ... | .... | 10.3 | ||||||

13.7 | ... | ... | 13.7 | ... | ||||||

16 | 16 | ... | ... | ... | ||||||

16 | ... | 16 | ... | ... | ||||||

12 | ... | ... | ... | 12 | ||||||

12 | ... | ... | ... | 12 | ||||||

16 | ... | ... | 16 | ... | ||||||

13.7 | ... | ... | ... | 13.7 | ||||||

16 | ... | ... | ... | 16 | ||||||

13.5 | 13.5 | ... | ... | ... | ||||||

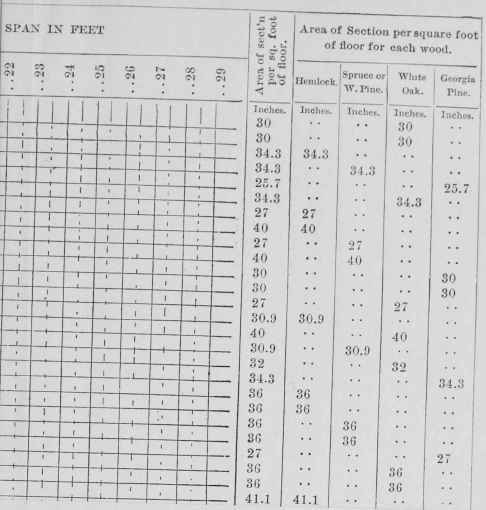

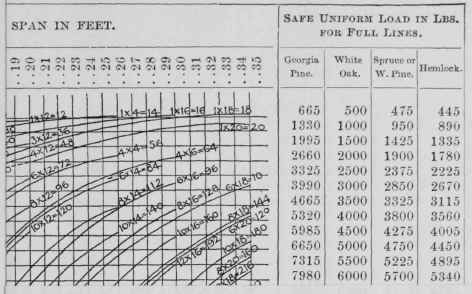

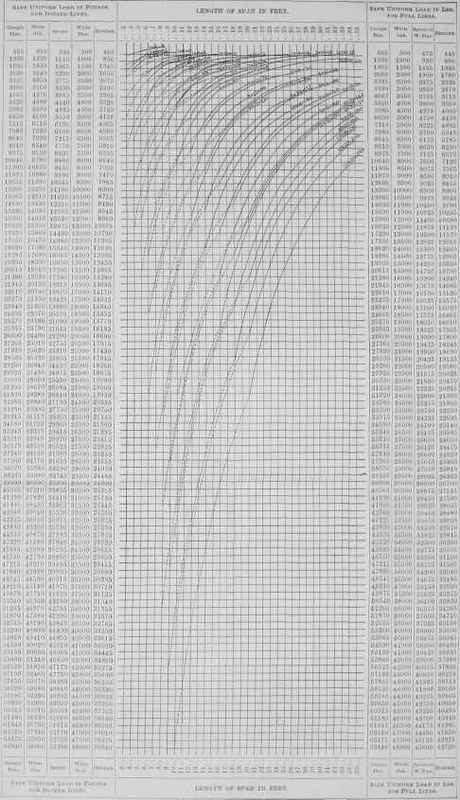

Table XII. Wooden Floor-Beams

[Calculated For 90 Founds Per Square Foot Of Floor.]

( Continued).

Table XII(Continued).

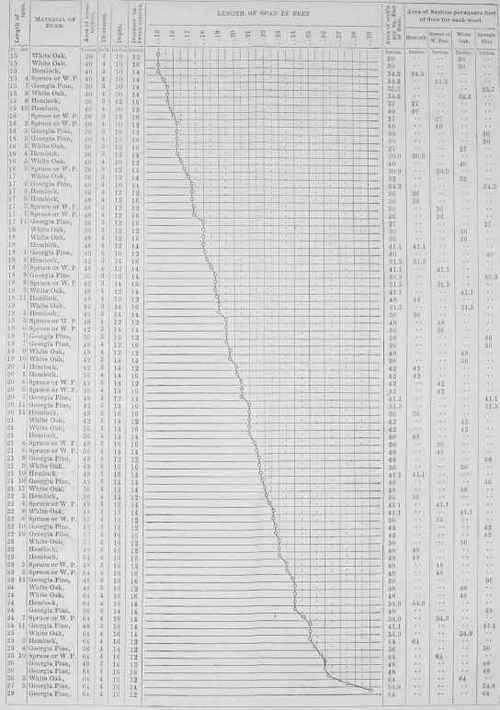

XIII. Braced Sideways

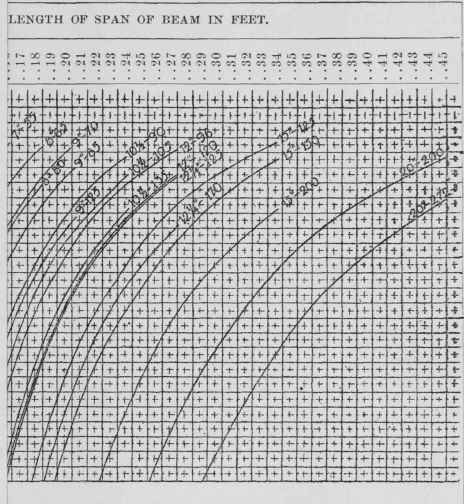

Table XIII. Wooden Girders, Braced Sideways

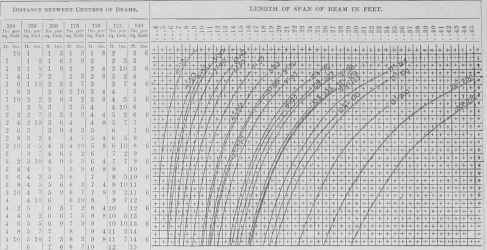

XIV For Floors

or Iron Beams; but length of span in feet must not exceed twice the depth

Table XIV. Iron I Beams For Floors

For Steel Beams, spone one-quarter listrnce (between in centres) larger than for Iron Beams; but length of span in feet must not exceed twice the depth of beam in inches, or deflection will be too great for plastering.

XIX. Tables XX To XXV

II ARE. UNIFORM ABOVE AND BELOW THE NEUTRAL AXIS. | |||||

MANNER OF LOADING. | TO OBTAIN SAFE LOAD IN FOUNDS. | LENGTH OF SPAN NOT TO CRACK PLASTERING MUST NOT EXCEED. | GREATEST ACTUAL DEFLECTION WILL BE. | ||

For Iron. | For Steel. | For Iron. | For Steel. | ||

| w1 = w11 = v/2 2/3. L or | L=2 3/16.d | L = l7/8.d | δ=L2/72 3/4.d | δ= L2/62 1/2.d |

w1 + w11 =v/1 1/3. L | |||||

| w111 = w1111 = v/2. L or: - | L = 2. d | L = l3/4.d | δ = L2/67.d | δ = L2/57 2/3.d |

w111+w1111 = v/L | |||||

ables XX to XXV; u = uniform load in lbs.; w = centre load in lbs.; w1,=-. w11also w111=conoencarfully, as steel varies greatly in strength. For equal deflections of steel and iron, add hetransverse values, the moduli of rupture used were: for iron, 12000 pounds per square as follows: - In case of uniform load deduct entire weight of beam; in case of centre m each load 3/8 the weight of beam; in case of loads at quarters of span, deduct from same dimensions. In ordering steel or iron, give either the required dimensions or the ble represent the following Rolling Mills: B - PHCENIX IRON COMPANY, Philadelphia, Pa. D - Pottsville'iron And Steel Company, Pottsville, Pa. pa. F - Passaic Rolling Mill Company, Passaic, N. J.

;es the Mill which rolls the exact shape given in the Table; the other letters give the

Tee

Zee

Deck Beam

Table XIX. Explaining Use Of Tables XX TO XXV

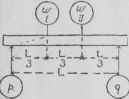

How to Use Transverse Value (v) for Sections which and Uniform above and below the Neutral Axis.

MANNER OF LOADING. | TO OUTAIN SAFE LOAD IN POUNDS. | LENGTH NOT TO RACE PLASTERING MUST NOT EXCEED. | CHEATEST ACTUAL DEFLECTION WILL BE | ||

For Iron. | For Steel. | For Iron. | For Steel. | ||

| u = v/L | L = 2 1/4.d | L = 2.d | δ = L2/75.d | δ = L2/64 1/2.d |

| w = v/2.L | L = 2 4/5.d | L = 2 2/5.d | δ = L2/93 3/4.d | δ = L2/80 2/3.d |

MANNER OF LOADING. | TO OBTAIN SAFE LOAD IN POUNDS. | LENGTH OF SPAN NOT TO CRACK PLASTERING BUST SOT EXCEED, | GREATEST ACTUAL REFLECTION WILL BE. | ||

For Iron. | For Steel. | For Iron. | For Steel. | ||

| w1 = w11 = v/2 2/3.L or: - | L=2 3/16.d | L = 1 7/8.d | δ = L2/72 3/4.d | δ =L2/62 1/2.d |

w1+w11 = v/1 1/3.L | |||||

| w111=w1111 = v/2.L or: - | L = 2.d | L. = l 3/4.d | δ = L2/67.d | δ =L2/57 2/3.d |

w111+w1111=v/L | |||||

d = depth in Indies; L =length in feet; δ = deflection in Inches; v = transverse value, as given in Tables XX to XXV; n : uniform load in lbs.; w=centre load in lbs.; w1 - w111. also w111 = w1111 concen-trated; loads in lbs.

Note. - It the transverse values (w), given for steel, are used, teal each piece carefully, as steel varies greatly in strength. For equal deflections of steel and iron, add only 7 1/2% to iron transverse values, instead of 2 i as given in Tables. In calculating the transverse values, the moduli of rupture used were: for iron, 12000 pounds per square inch,and for steel, 15000 pounds per square inch.

From the "Safe Load" as obtained above, deduct the weight of beam in pounds, as follows: - In ease of uniform load deduct entire weight of beam; in case of centre load, deduct one-half the weight of beam; in case of loads at thirds of span, deduct from each load 3/5 the weight, of beam; in case of loads at quarters of span, deduct from each load 1/2 the weight of be beam,

Steel sections will be slightly heavier (about 1%) than iron sections of exactly the same dimensions. In ordering steel or iron, give either the required dimensions or the required weight of section, never both.

The capital letters in the first column headed -Mills Rolling Shape" in each Table represent the following Rolling Mills: A - New Jersey Steel And Iron Company, Trenton, N. J. R - Phoinix Iron Company, Philadelphia, Pa.

C - Pencoyd Iron Works, Philadelphia, Pa. D - Pottsville Iron And Steel Company, Pottsville, Pa.

E - Union Iron Mills And Homestead Steel Works, Pittsburgh, Pa. F - Passaic Rolling Mill Company, Passaic, N. J.

In the columns headed "Mills Rolling Shape" the first letter on each line indicates the Mil! which rolls the exact shape given in the Table; the other letters give the Mills which roll an approximately similar shape.

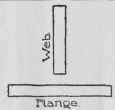

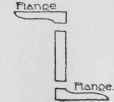

In getting the areas of parts of sections, they were taken as shown below: beam.

Channel

Angle

Tee

Cee

Deck Beam XX Steel I Beams

of this Table, see Table XIX.)

tal to Web. | |||

(r) | Square of Radius of Gyration. (ρ2) | Transverse Value (v) in lbs. | |

For Iron. | For Steel. | ||

6 | 60.67 | 1320000 | 1650000 |

6 | 60.42 | 1160000 | 1450000 |

6.8 | 61.99 | 990000 | 1238000 |

4.6 | 59.68 | 917000 | 1146000 |

9 | 34.80 | 552000 | 690000 |

8.5 | 35.32 | 748000 | 935000 |

7.5 | 35.15 | 460000 | 575000 |

8 | 32.52 | 864000 | 1080000 |

9 | 31.24 | 800000 | 1000000 |

2.5 | 34.70 | 740000 | 925000 |

4.5 | 31.47 | 655000 | 819000 |

0.4 | 35.20 | 563000 | 704000 |

0.5 | 35.76 | 556000 | 695000 |

7.3 | 34.40 | 458000 | 573000 |

3.5 | 23.32 | 508000 | 635000 |

3 | 22.60 | 504000 | 630000 |

7 | 23.35 | 376000 | 470000 |

5.7 | 18.92 | 454000 | 567000 |

8.7 | 22.46 | 510000 | 637000 |

7.1 | 22.60 | 377000 | 471000 |

6.9 | 23.98 | 375000 | 469000 |

6.3 | 21.80 | 290000 | 363000 |

8.2 | 24.22 | 306000 | 382000 |

4.5 | 17.49 | 356000 | 445000 |

5.3 | 17.77 | 282000 | 353000 |

.4 | 17.39 | 251000 | 314000 |

.2 | 18.42 | 250000 | 312000 |

7.5 | 13.91 | 300000 | 375000 |

4.7 | 15.52 | 278000 | 347000 |

5.2 | 15.35 | 258000 | 322000 |

9.7 | 16.40 | 237000 | 297000 |

2 | 12.63 | 336000 | 420000 |

5.3 | 11.70 | 282000 | 353000 |

5.5 | 12.23 | 268000 | 335000 |

6 | 11.83 | 208000 | 260000 |

5.4 | 13.10 | 211000 | 264000 |

4.9 | 13.16 | 199000 | 249000 |

0.9 | 13.41 | 167000 | 209000 |

2.6 | 8.64 | 181000 | 226000 |

1 | 10.44 | 168000 | 210000 |

Axis Parallel to Web. | ||||

Moment of Intertia. (r) | (r) | Square of Radius of Cyration. (ρ2) | Transverse Value (v) in lbs. | |

For Iron. | For Steel. | |||

46.50 | 13.78 | 1.71 | 110000 | 137800 |

51.78 | 16.57 | 2.16 | 132600 | 165700 |

26.62 | 8.87 | 1.33 | 71000 | 88700 |

31.50 | 10.08 | 1.64 | 80600 | 100800 |

15.29 | 6.12 | 1.02 | 49000 | 61200 |

27.46 | 9.55 | 1.37 | 76000 | 95500 |

11.64 | 4.66 | .94 | 37000 | 46600 |

40.84 | 13.90 | 1.62 | 111200 | 139000 |

29.90 | 10.29 | 1.25 | 82300 | 103000 |

33.79 | 12.12 | 1.69 | 97000 | 121000 |

20 | 7.50 | 1.02 | 60000 | 75000 |

18.34 | 7.34 | 1.22 | 58700 | 73400 |

16.91 | 6.60 | 1.17 | 52800 | 66000 |

13.13 | 5.34 | 1.05 | 42700 | 53400 |

25.41 | 9.24 | 1.52 | 74000 | 92400 |

20.90 | 7.96 | 1.23 | 63700 | 80000 |

11.54 | 4.82 | .93 | 38500 | 48200 |

15.50 | 6.09 | .86 | 48700 | 61000 |

24.08 | 8.76 | 1.42 | 70100 | 87600 |

12.98 | 5.46 | 1.04 | 43700 | 54600 |

16.76 | 6.10 | 1.43 | 49000 | 61000 |

8.74 | 4 | .87 | 32000 | 40000 |

11.66 | 4.44 | 1.23 | 35500 | 44400 |

15.80 | 6.32 | 1.18 | 50500 | 63200 |

9.43 | 4.19 | .90 | 33500 | 41900 |

8.01 | 3.53 | .85 | 28200 | 35300 |

8.09 | 3.59 | .91 | 28700 | 35900 |

11.30 | 4.74 | .83 | 37900 | 47400 |

10.64 | 4.60 | .96 | 36800 | 46000 |

11.08 | 4.79 | 1.05 | 38300 | 48000 |

8.09 | 3.69 | .90 | 29500 | 36900 |

23.16 | 8.62 | 1.54 | 69000 | 86000 |

14 | 5.67 | 1.02 | 45400 | 56700 |

11.23 | 4.99 | .91 | 40000 | 49900 |

7.14 | 3.30 | .72 | 26400 | 33000 |

8.44 | 3.86 | .92 | 30900 | 38600 |

7.35 | 3.27 | .86 | 26000 | 32700 |

4.92 | 2.46 | .70 | 19700 | 24600 |

6.96 | 3.25 | .67 | 26000 | 32500 |

7.55 | 3.35 | .93 | 26800 | 33500 |

Table XX. List Of Iron And Steel I Beams

(For Information- as to the Use of This Table, see Table XIX.)

MILLS ROLLING SEALE | Depth of Beam. (d) | Weight per Yard. | Width of Fiancee. (b) | Thickness of Web. | Area of each Flange, | Area of Web. | Total Area. (a) | Axis Normal to Web. | Axis Parallel to Web. | ||||||||

Moment of Intertia. (r) | Moment of Restance. (r) | square of Resistanc ρ2 | Transverse Value (v) in lbs. | Moment of Intertia (r) | Moment of Resistance (r) | Square of Redins. of Gymlton (ρ2) | Transverse Value (v) in lbs. | ||||||||||

For Iron. | For Steel. | For Iron. | For Steel. | ||||||||||||||

A.B......... | 20 | 272 | 6.75 | 0.69 | 7.87 | 11.46 | 27.20 | 1650.3 | 165 | 60.67 | 1320000 | 1650000 | 46.50 | 13.78 | 1.71 | 110000 | 137800 |

E........... | 20 | 240 | 7 | 0.60 | 6.68 | 10.64 | 24 | 1450 | 145 | 60.42 | 1160000 | 1450000 | 51.78 | 16.57 | 2.16 | 132600 | 165700 |

A,B......... | 20 | 200 | 6 | 0.50 | 5.65 | 8.67 | 19.97 | 1238 | 123.8 | 61.99 | 990000 | 1288000 | 26.62 | 8.87 | 1.33 | 71000 | 88700 |

E........... | 20 | 192 | 6.25 | 0.50 | 5.09 | 9.02 | 19.20 | 1146 | 114.6 | 59.68 | 917000 | 1146000 | 31.50 | 10.08 | 1.64 | 80600 | 100800 |

A.F......... | 15 9/16 | 150 | 5 | 0.50 | 4.34 | 6.36 | 15.04 | 523.5 | 69 | 34.80 | 552000 | 690000 | 15.29 | 6.12 | 1.02 | 49000 | 61200 |

A.F................. | 15 1/8 | 200 | 5.75 | 0.60 | 6.44 | 7.11 | 20.02 | 707.1 | 93.5 | 35.32 | 748000 | 935000 | 27.46 | 9.55 | 1.37 | 76000 | 95500 |

A........... | 15 1/8 | 125 | 5 | 0.42 | 3.37 | 5.62 | 12.36 | 434.5 | 57.5 | 35.15 | 460000 | 575000 | 11.64 | 4.66 | .94 | 37000 | 46600 |

D................... | 15 | 250 | 5.875 | 0.875 | 7.22 | 10.56 | 25 | 813 | 108 | 32.52 | 864000 | 1080000 | 40.84 | 13.90 | 1.62 | 111200 | 139000 |

E........... | 15 | 240 | 5.81 | 0.93 | 6.29 | 11.42 | 24 | 750 | 100 | 31.24 | 800000 | 1000000 | 29.90 | 10.29 | 1.25 | 82300 | 103000 |

D,B,C,E.... | 15 | 200 | 5.56 | 0.625 | 8.06 | 7.86 | 20 | 694 | 92.5 | 34.70 | 740000 | 925000 | 33.79 | 12.12 | 1.69 | 97000 | 121000 |

E........... | 15 | 195 | 5.33 | 0.77 | 4.84 | 9.82 | 19.50 | 614 | 81.5 | 31.47 | 655000 | 819000 | 20 | 7.50 | 1.02 | 60000 | 75000 |

D,B,E....... | 15 | 150 | 5 | 0.47 | 4.47 | 6.0G | 15 | 528 | 70.4 | 35.20 | 563000 | 704000 | 18.34 | 7.34 | 1.22 | 58700 | 73400 |

C........... | 15 | 145 | 5.125 | 0.44 | 4.48 | 5.59 | 14.55 | 621.2 | 69.5 | 35.70 | 556000 | 695000 | 16.91 | 6.60 | 1.17 | 52800 | 66000 |

D,B,E....... | 15 | 125 | 4.875 | 0.44 | 3.35 | 5.80 | 12.50 | 430 | 57.3 | 34.40 | 458000 | 573000 | 13.13 | 5.34 | 1.05 | 42700 | 58400 |

A.......... | 12 5/16 | 170 | 5.50 | 0.60 | 5.47 | 6.83 | 16.77 | 391.2 | 63.5 | 23.32 | 508000 | 635000 | 25.41 | 9.24 | 1.52 | 74000 | 92400 |

F........... | 12 1/4 | 170 | 5.25 | 0.66 | 5.66 | 5.88 | 17 | 385 | 63 | 22.60 | 504000 | 630000 | 20.90 | 7.96 | 1.23 | 63700 | 80000 |

A,F......... | 12 1/2 | 125 | 4.79 | 0.47 | 3.78 | 4.77 | 12.33 | 288 | 47 | 23.35 | 376000 | 470000 | 11.54 | 4.82 | .93 | 38500 | 48200 |

E........... | 12 | 180 | 5.09 | 0.96 | 4.26 | 9.48 | 18 | 340 | 56.7 | 18.92 | 454000 | 567000 | 15.50 | 6.09 | .86 | 48700 | 61000 |

B,C,D....... | 12 | 170 | 5.50 | 0.59 | 6.77 | 5.4G | 17 | 381.9 | 63.7 | 22.46 | 510000 | 637000 | 24.08 | 8.76 | 1.42 | 70100 | 875000 |

B,D,E....... | 12 | 125 | 4.75 | 0.49 | 3.80 | 4.90 | 12.50 | 282.6 | 47.1 | 22.60 | 377000 | 471000 | 12.38 | 5.46 | 1.04 | 43700 | 54600 |

A,C......... | 12 | 120 | 5.50 | 0.39 | 3.87 | 3.99 | 11.73 | 281.3 | 46.9 | 23.98 | 375000 | 469000 | 16.76 | 6.10 | 1.43 | 49000 | 61000 |

D........... | 12 | 100 | 4.44 | 0.44 | 2.71 | 4.58 | 10 | 218 | 36.3 | 21.80 | 290000 | 363000 | 8.74 | 4 | .87 | 32000 | 40000 |

A,B,E....... | 12 | 96 | 5.25 | 0.31 | 3.09 | 3.28 | 9.46 | 229.2 | 38.2 | 24.22 | 306000 | 382000 | 11.66 | 4.44 | 1.23 | 35500 | 44400 |

A,B,C,D,E,F, | 101 | 135 | 5 | 0.47 | 4.84 | 3.68 | 13.36 | 238.7 | 44.5 | 17.49 | 356000 | 445000 | 15.80 | 0.32 | 1.18 | 50500 | 63200 |

A,B,C,D,F... | 10 1/2 | 105 | 4.50 | 0.375 | 3.67 | 3.10 | 10.14 | 185.6 | 85.3 | 17.77 | 282000 | 353000 | 9.43 | 4.19 | .90 | 33500 | 41900 |

E........... | 10 1/2 | 95 | 4.54 | 0.41 | 2.96 | 3.58 | 9.50 | 165 | 31.4 | 17.39 | 251000 | 314000 | 8.01 | 3.53 | .85 | 28200 | 35300 |

A,B,C,D,F... | 10 1/2 | 90 | 4.50 | 0.31 | 3.11 | 2.68 | 8.90 | 104 | 31.2 | 18.42 | 250000 | 312000 | 8.09 | 3.59 | .91 | 28700 | 35900 |

E........... | 10 | 135 | 4.77 | 0.77 | 3.67 | 6.16 | 13.50 | 187 | 37.5 | 13.91 | 300000 | 375000 | 11.30 | 4.74 | .83 | 37900 | 47400 |

C ........... | 10 | 112 | 4.625 | 0.50 | 3.61 | 3.95 | 11.17 | 173.6 | 31.7 | 15.52 | 278000 | 347000 | 10.64 | 4.60 | .96 | 36800 | 46000 |

D........... | 10 | 105 | 1.625 | 0.50 | 3.24 | 4.02 | 10.50 | 161 | 32.2 | 15.35 | 258000 | 322000 | 11.08 | 4.79 | 1.05 | 38300 | 48000 |

C,D,E....... | 10 | 90 | 4.375 | 0.34 | 3.14 | 2.76 | 9.04 | 148.3 | 29.7 | 16.40 | 237000 | 297000 | 8.09 | 3.69 | .90 | 29500 | 36900 |

B,E......... | 9 | 150 | 5.375 | 0.60 | 5.59 | 3.82 | 15 | 189.1 | 42 | 12.63 | 336001 | 420000 | 23.16 | 8.62 | 1.54 | 69000 | 86000 |

E ........... | 9 | 135 | 1.94 | 0.75 | 4.22 | 6.0G | 13.50 | 159 | 35.3 | 11.70 | 282000 | 353000 | 14 | 5.67 | 1.02 | 45400 | 56700 |

A........... | 9 | 125 | 4.50 | 0.57 | 4.41 | 3.51 | 12.33 | 150.8 | 33.5 | 12.23 | 268000 | 335000 | 11.23 | 4.99 | .91 | 40000 | 49900 |

E........... | 9 | 99 | 4.33 | 0.58 | 2.85 | 4.20 | 9.90 | 117 | 26 | 11.83 | 208000 | 260000 | 7.14 | 3.30 | .72 | 26400 | 33000 |

CD......... | 9 | 90 | 4.375 | 0.41 | 3.07 | 2.93 | 9.07 | 118.8 | 26.4 | 13.10 | 211000 | 264000 | 8.44 | 3.86 | .92 | S0900 | 38600 |

A,B,D,F..... | 9 | 85 | 4.50 | 0.375 | 2.93 | 2.64 | 8.50 | 111.9 | 24.9 | 13.16 | 199000 | 249000 | 7.35 | 3.27 | .86 | 26000 | 32700 |

A,B,C,D,E,F, | 9 | 70 | 4 | 0.30 | 2.40 | 2.20 | 7 | 93.9 | 20.9 | 13.41 | 167000 | 209000 | 4.92 | 2.46 | .70 | 19700 | 24600 |

E........... | 8 | 105 | 4.29 | 0.79 | 2.74 | 5.02 | 10.50 | 90.4 | 22.6 | 8.64 | 181000 | 226000 | 6.96 | 3.25 | .67 | 26000 | 32500 |

A,B,C,D,F... | 8 | 80 | 4.50 | 0.375 | 2.82 | 2.39 | 8.03 | 83.9 | 21 | 10.44 | 168000 | 210000 | 7.55 | 3.35 | .93 | 26800 | 38500 |

A,B,C,D,E,F, | 8 | G5 | 4 | 0.30 | 2.21 | 1.95 | 6.37 | 67.4 | 16.9 | 10.58 | 135000 | 169000 | 4.55 | 2.27 | .71 | 18200 | 22700 |

E........... | 7 | 75 | 3.91 | 0.53 | 2.29 | 2.92 | 7.50 | 54.3 | 15.5 | 7.24 | 124000 | 155000 | 4.87 | 2.50 | .66 | 20000 | 25000 |

B........... | 7 | 69 | 4 | 0.375 | 2.47 | 1.96 | 6.90 | 55.7 | 15.9 | 8.08 | 127000 | 159000 | 5.42 | 2.71 | .785 | 21680 | 27100 |

CD......... | 7 | 65 | 3.81 | 0.44 | 2.08 | 2.42 | 6.58 | 49.8 | 14.2 | 7.56 | 113800 | 142000 | 4.15 | 2.18 | .62 | 17400 | 21800 |

F........... | 7 | 60 | 3.50 | 0.40 | 1.88 | 2.24 | 6 | 45 | 12.9 | 7.50 | 103200 | 129000 | 3.15 | 1.80 | .53 | 14400 | 18000 |

A,B.D,E .... | 7 | 55 | 3.75 | 0.30 | 1.90 | 1.70 | 5.50 | 44.3 | 12.7 | 8.05 | 101001 | 127000 | 3.90 | 2.08 | .71 | 16600 | 20800 |

G........... | 7 | 52 | 3.61 | 0.234 | 1.92 | 1.30 | 5.14 | 43.1 | 12.3 | 8.35 | 98500 | 123000 | 3.43 | 1.90 | .67 | 15200 | 19000 |

A........... | 6 | 120 | 5.25 | 0.625 | 4.78 | 2.28 | 11.84 | 64.9 | 21.6 | 5.48 | 172000 | 216000 | 18.59 | 7.08 | 1.57 | 56600 | 70800 |

A,F......... | 6 | 90 | 5 | 0.50 | 3.31 | 2.08 | 8.70 | 49.8 | 16.6 | 5.72 | 132001 | 106000 | 10.78 | 4.32 | 1.24 | 34500 | 43200 |

E.......... | 6 | 54 | 3.46 | 0.46 | 1.61 | 2.18 | 5.40 | 28.4 | 9.5 | 5.29 | 76000 | 950000 | 2.51 | 1.45 | .46 | 11600 | 14500 |

A,B,C,D,F... | 6 | 50 | 3.50 | 0.30 | 1.77 | 1.37 | 4.91 | 29 | 9.6 | 5.90 | 76800 | 96000 | 2.74 | 1.57 | .56 | 12500 | 15700 |

A.B,C,D,E,F, | 6 | 40 | 3 | 0.25 | 1.42 | 1.17 | 4.01 | 23.5 | 7.8 | 5.86 | 62400 | 78000 | 1.61 | 1.07 | .40 | 8500 | 10700 |

A,D,E,F..... | 5 | 40 | 9 | 0.31 | 1.36 | 1.18 | 3.90 | 15.4 | 6.1 | 3.95 | 48800 | 61000 | 1.68 | 1.12 | .43 | 9000 | 11200 |

B........... | 5 | 36 | 3 | 0.30 | 1.20 | 1.20 | 3.60 | 14.9 | 5.96 | 4.14 | 47700 | 59600 | 1.74 | 1.16 | .483 | 9260 | 11580 |

C............. | 5 | 34 | 2.844 | 0.31 | 1.06 | 1.26 | 3.38 | 13.4 | 5.4 | 3.96 | 42800 | 53500 | 1.21 | .85 | .36 | 6800 | 8500 |

A,B,C,D,E,F, | 5 | 30 | 2.75 | 0.25 | .99 | 1.01 | 2.99 | 12.1 | 4.8 | 4.04 | 38400 | 48000 | 1.04 | .76 | .35 | 6000 | 7600 |

A,F......... | 4 | 37 | 3 | 0.S1 | 1.40 | .86 | 3.66 | 9.2 | 4.6 | 2.51 | 36800 | 46000 | 1.74 | 1.16 | .48 | 9500 | 11G00 |

A,B,D,E,F .. | 4 | 30 | 2.75 | 0.25 | 1.08 | .75 | 2.91 | 7.5 | 3.75 | 2.57 | 30000 | 37500 | 1.11 | .81 | .38 | 6500 | 8100 |

C........... | 4 | 28 | 2.75 | 0.25 | 1.07 | .76 | 2.90 | 7.7 | 3.84 | 2.65 | 30700 | 38400 | 1.17 | .85 | .40 | 6800 | 8500 |

D,E......... | 4 | 24 | 2.25 | 0.81 | .71 | .98 | 2.40 | 5.6 | 2.80 | 2.33 | 22400 | 28000 | .58 | .52 | .22 | 4160 | 5200 |

A,B,C,D,F .. | 4 | 18 | 2 | 0.19 | .58 | .61 | 1.77 | 4.5 | 2.25 | 2.54 | 18000 | 22500 | .31 | .31 | .175 | 2500 | 8100 |

E..... | 3 | 27 | 2.52 | 0.39 | .93 | .84 | 2.70 | 3.54 | 2.36 | 1.32 | 18900 | 23600 | .84 | .67 | .31 | 5360 | 6700 |

C...... | 3 | 23 | 2.50 | 0.25 | .86 | .53 | 2.25 | 3.29 | 2.16 | 1.46 | 17300 | 21600 | .77 | .62 | .35 | 4960 | 6200 |

E........... | 3 | 21 | 2.32 | 0.19 | .85 | .40 | 2.10 | 3.09 | 2.06 | 1.46 | 16500 | 20600 | .55 | .47 | .30 | 3760 | 4700 |

C........... | 3 | 17 | 2.25 | 0.156 | .68 | .35 | 1.71 | 2.66 | 1.77 | 1.56 | 14200 | 17700 | .48 | .43 | .28 | 3440 | 4300 |

A........... | 1 1/4 | 5 1/4 | 1.50 | 0.125 | .19 | .14 | .52 | .135 | .21 | .26 | 2160 | .06 | .092 | .013 | ...... | 920 | |

Continue to:

)

)