Jigs With Legs

Description

This section is from the book "Modern Shop Practice", by Howard Monroe Raymond. Also available from Amazon: Modern Shop Practice.

Jigs With Legs

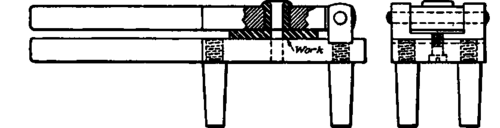

When jigs are made for permanent equipment, or if they are to be used constantly, it is well to provide some means of elevating them from the drill-press table to avoid inaccurate work occasioned by chips. If the jig is of cast iron, the legs are sometimes cast solid with the jig, as shown in Fig. 282. In order that the jig handle may be grasped in a manner that will not tire the wrist or hand, and in order to give sufficient room between the handle and the table of the drill press so that the fingers may not be cut by chips, the legs should be made of a length that will raise the handle about 1$ inches above the table. As cast-iron legs of this length would be too weak, it is customary to make the legs of tool steel, hardening the ends that come in contact with the drill-press table.

Fig. 282. Cast-Iron Jig with Solid Cast Legs.

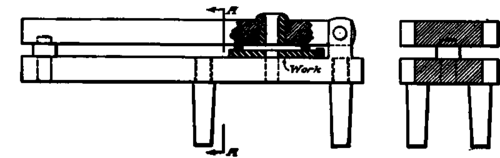

Fig. 283. Jig with Cover.

Fig. 284. Covered Jig Showing Space between Work and Leaf.

Continue to: