Forging Tongs

Description

This section is from the book "Modern Shop Practice", by Howard Monroe Raymond. Also available from Amazon: Modern Shop Practice.

Forging Tongs

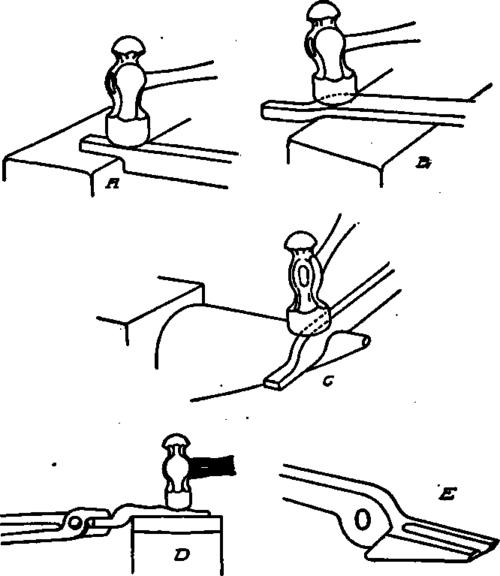

Common flat-jawed tongs, such as are used for holding light work, may be made as follows: The stock should be about 1 inch by 3/4 inch. The first step should be to work the stock down over the edge of the anvil, as shown at A, Fig. 76. Turn the flat side at an angle of about 45 degrees on anvil as shown at B, and work down to half the thickness of the jaw hammered out. Then work down the stock on the round horn of the anvil, as shown at C. Then draw out the handle, as shown at D, allowing enough stock to work out the proper length; or a small amount of stock may be taken, a short stub drawn out, and the round stock welded on, making the proper length as shown in Fig. 77. The last step is to punch the hole for the rivet. It is always a good plan to slightly increase the inside face of the jaw with a fuller, as shown at E, Fig. 76, as this insures the jaws gripping the work firmly with the edges, and not touching it simply at one point in the center, as they sometimes do if this crease is not made. The tongs are then riveted together, the riveting being done with the round end of the hammer; in this way a head is formed on the rivet without upsetting the shank of the rivet very much where it passes through the hole. After riveting, the tongs will probably be stiff or hard to move. They may be loosened up by heating the eye part red hot and moving the handles forward and backward two or three times. They should then be firmly fitted to the work to be handled.

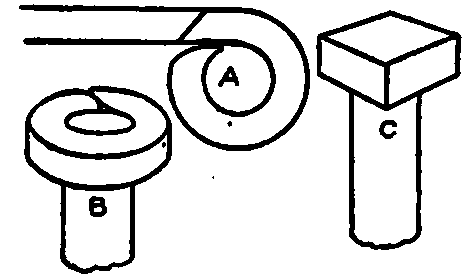

Fig. 75. Welded-Head Bolt.

Fig. 76. Steps in Making Flat-Jawed Tongs.

Fig. 77. Welding-On Round Stock.

Tongs For Round Stock

Tongs for handling round stock may be made by the general method described above, the only difference being that after the jaws are shaped, and before riveting together, they should be rounded up as illustrated in Fig. 78, using a fuller and swage as shown*

Light Tongs

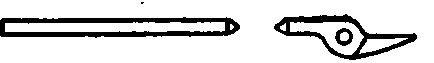

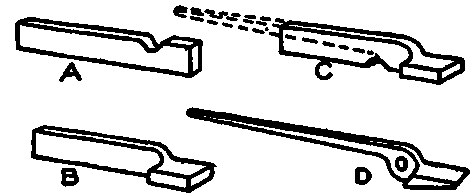

Light tongs may be made from flat stock in the manner illustrated in Fig. 79. With a fuller, a cut is made near one end in a piece of flat stock, as at A. This end is twisted over at right angles as shown at B. Another cut is made on the opposite side, as at C, and the end drawn out as indicated by the dotted lines. The tongs are then finished in the usual way. Tongs of this character may be used for very light work and are easily made.

Fig. 78. Method of Making Jaws for Round-Nose Tongs.

Fig. 79. Light Tonga Made from Flat Stock.

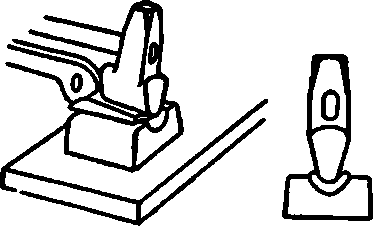

Fig. 80. Method of Forging Pick-Up Tongs.

Pick-Up Tongs

Pick-up tongs are made in much the same way as described above, the different steps being illustrated in Fig. 80.

Bolt Tongs

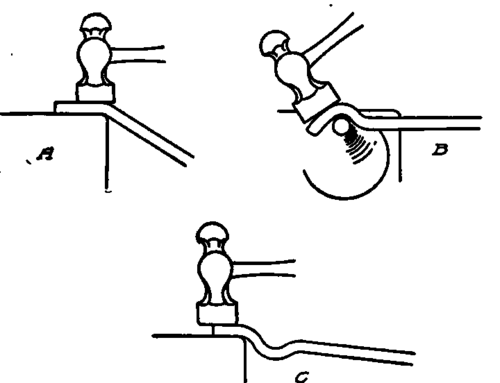

Bolt tongs may be made from round stock, although square may be sometimes used to advantage. The first step is to bend the bar in the shape shown in Fig. 81, which may be done by the hammer at the edge of the anvil, shown at A, and on the anvil horn as at B. The jaw proper is rounded and finished as shown at C. The part between the jaw proper and the eye may be worked down into shape by the fuller and set hammer. The finishing may be done as indicated in Fig. 82. The eye and handle are then flattened down and drawn out, the tongs are punched, riveted together, finished, and fitted in the usual manner.

Fig. 81. Steps in Making Bolt Tongs.

Continue to: