Brazing Keys

Description

This section is from the book "Cassell's Cyclopaedia Of Mechanics", by Paul N. Hasluck. Also available from Amazon: Cassell's Cyclopaedia Of Mechanics.

Brazing Keys

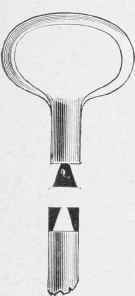

Brazing is another name for hard soldering; the process differs from ordinary soft soldering principally in the fact that the uniting metal or spelter is not applied with a hot bit. Greater heat is required to melt the spelter than is necessary for soft solder, it being necessary to employ either a forge fire or a powerful blowpipe to make the hard spelter flow into the joint. Bi-azing is used where greater strength is required than can be given by soft solder, or when an article has to stand a degree of heat that would cause soft solder to melt. In brazing together the broken parts of a key stem, first it is necessary to file the fractured ends quite true; this may entail the shortening of the key by 1/4 in. or 1/2 in., and as another i in. will be lost in making the joint, it may be advisable to use another key bow having a longer piece of stem than the one which was broken off. With a warding file cut a dovetail on each of the ends to be joined, as shown by Fig. 1. A small, half-round file will assist in making the edges true and square. The pieces must interlock perfectly, and when this is the case, very lightly hammer the joint, around which then bind seven or eight turns of brass wire to act as spelter. Wet the joint, sprinkle powdered borax on it (this is to serve as the flux), and, holding the key in a pair of tongs, place it in a clear part of a forge lire made with charcoal, small coke, or coal cinders, and commence to blow steadily the forge bellows or blower. Failing a forge fire, use a blowpipe, the key being placed on a piece of charcoal or pumice-stone whilst the heat is being applied. A blowpipe for brazing requires a greater pressure of air than can be given by the mouth, so the blowpipe must be connected to a blower. The air pressure regulates the temperature of the flame, and to get a sharp, concentrated heat, an air pressure of from l1b. to 1 1/2 lb. on the square inch is required. Such a pressure is obtained easily from a foot blower. If the forge fire is used it is as well to support the key on a guard of thick iron plate having a hole in its centre over which is the joint to be brazed. By this means the necessary local heating is obtained, and much labour in cleaning the key afterwards is avoided.

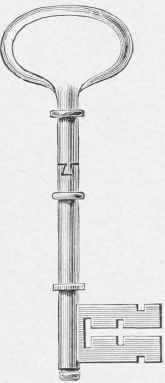

On being heated, the borax swells and boils up, and should he pressed down with a spatula, previously dipped in cold water to prevent the hot borax adhering to it; a suitable spatula is made by flattening one end of a 1-ft. length of a 1/4-in. round rod, having at its other end an eye by which it may be hung when not in use. With this spatula, also, powdered spelter may be added to the joint if required. When the brass wire commences to run, assist the flow by adding powdered borax, and when all the brass has run into the joint, rub off superfluous molten metal from underneath and allow the joint to cool gradually. When cold, file up and clean the stem of the key until only a thin bright line of brass can be seen. Fig. 2 shows the finished key.

Fig. 1.

Fig. 2. Brazing Keys.

Continue to: