Laying Marble Mosaic Pavement

Description

This section is from the book "Cassell's Cyclopaedia Of Mechanics", by Paul N. Hasluck. Also available from Amazon: Cassell's Cyclopaedia Of Mechanics.

Laying Marble Mosaic Pavement

The materials commonly used for marble mosaic paving are known us burnt marbles - that is, pure marbles burnt to the desired colours, such as rouge royal (red) and Russe cotto (red), with yellows, blues, greens, and greys of various shades, according to the amount of time spent in burning. The natural marbles used in their original form are chiefly St. Ann's marble and Carrara and Irish green. The cubes may measure about 5/8 in. square, though the size of the cubes depends on the area of the floor to be covered; but the cubes generally used are from; in. to 3/4 in. square, and are either sawn or cut by hand to the required dimensions; For each floor only one size of cube is used. The tesserae are fixed with a cementing material consisting of chalk lime slaked with water, and left in the open air for several days until it is killed; it is then sifted and mixed with a large proportion of fine crushed brick and water, and well beaten up with wooden beaters into a fine mellowed mortar ready for immediate use.

The floor for the reception of the mosaic is generally formed of Portland cement concrete, floated over to a fairly true face; the mortar is now spread evenly on the floor, and the cubes of marble are laid to the required pattern, a small hammer being used for tapping the cubes in until they are solidly bedded. The floor is afterwards rolled with a moderately heavy roller, and then left for a time until the tessera? are set, when the inequalities on the surface of the floor are rubbed off with specially constructed rubbers of sharp grit stone, water being freely used in the process. The face of the floor is rubbed very fine and left quite smooth, and finally finished off with linen rubbers. But a method very generally followed is to arrange the cubes on paper in the workshop, the first step in carrying out the work being to get out a design for the floor. From this design copies are made at full-size scale, usually on brown paper, ready for the workmen. Great care must be taken to ascertain that the whole of the design is reversed on the brown paper, as, the cubes being laid on the paper in the workshop, the paper would be uppermost on the job, and if the design were not reversed it would show the wrong way.

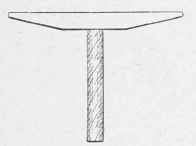

The workman's paper, when finished, is cut up into convenient lengths (about 3ft. 6 in.), marked with numbers from 1 consecutively, and handed over to the shop workmen, who require the following tools. A scab-bling hammer (see illustration), about 11 in. long and 1 in. square, tapered each end and fitted to a short handle, a pair of callipers, an iron block about 9 in. long by 4 in. by i in., granite rollers, straightedges, and rubbers. The workman now proceeds to pick out the necessary colours of cubes, dresses the cubes with the scabbling hammer to suit the design, and covers a portion of the design with a layer of gum, to which he attaches the cubes, doing small portions at a time until the whole is completed. The design having been completed by the shop workmen, the whole is forwarded to the scene of the job. The mosaic layer is given a plan of the floor marked with numbers corresponding to those marked on the mosais paper. Having laid the paving out on the job, the mosaic layer next prepares the cement, to which he fixes the marble slabs.

After two or more days, the cement having become set, the paper is cleared off, and the whole of the paving is subjected to con iderable rubbing with fine grit stone, attached to a wood handle having a V-groove. The paving is completed by being rubbed to a level.

Scabbling Hammer for Laying Marble Mosaic.

Continue to: