Coal Mine. Continued

Description

This section is from the book "The Engineer's And Mechanic's Encyclopaedia", by Luke Hebert. Also available from Amazon: Engineer's And Mechanic's Encyclopaedia.

Coal Mine. Continued

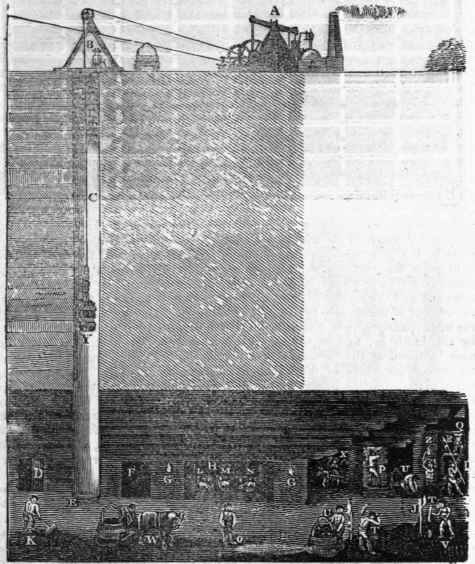

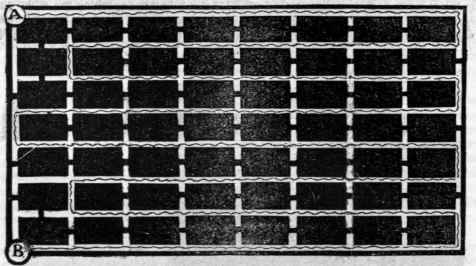

The different strata that are cut through to arrive at the principal bed of the coal are exhibited on the left of the shaft, by variously shaded portions of the solid earth, extending in the Bradley mine to the depth of about 111 feet, - the depth to the bottom of the shaft is 139 feet 4 inches. In the extensive collieries in the vicinity of Newcastle a complicated and expensive system of ventilation has been adopted, in order to guard against the disastrous consequences which result from an accumulation of fire-damp or hydrogen gas; but from the calamitous explosions, which are of such frequent occurrence, it is but too clear that the system is deplorably inefficient, and calls loudly for improvement. The accompanying sketch represents, on a small scale, the plan which is pursued to counteract the effects of that fatal evil, and to spread throughout the workings a sufficient quantity of fresh air. The dark parts in the plan represent the pillars of coal left to support the roof, and the light parts the workings. There are generally two descents or more to the mine, as we have already stated, which are distinguished by the terms of the downcast and upcast shaft.

A is the downcast shaft by which the air descends; the current of the air is represented by the waved line, which is carried through the main passages only, the subways which diverge from them being stopped by the brattices; and its motion is accelerated by the heat of a large furnace, situated at the bottom of the upcast shaft B; and thus the air, after traversing the whole of the workings, ascends the shaft B. An exhausting pump placed near the upper end of the upcast shaft B is sometimes substituted for the dangerous expedient of the furnace at the bottom of the shaft. But when particular parts of the mine are subject to rapid accumulations of firedamp, recourse is had to the firing process, which is usually performed by means of an apparatus, consisting of a long pole, or a series of poles, fitting one into another like a fishing-rod, so as to be elevated to the break, or pot-hole, where the fire-damp has accumulated; at the upper end of this pole is a small sheeve or wheel, over which a copper wire passes, of sufficient length to reach to the horse stable from any part of the mine; this done, the pole is firmly fixed in the place where the gas lodges.

A candle, fixed to a piece of lead or other substance to keep it upright when suspended, is carried by the fireman as far towards the explosive region as safety will admit, when it is set upon the floor, and fastened to one end of the copper wire, after which the firemen retire to the stable, which is made strong and well secured, in order to barricade them: the other end of the wire is brought through a crevice in the door, and by this means the light is drawn up to its destination; and the gas which has accumulated, coming in contact with the flame, ignites and explodes. In some instances the firemen remain pent up a considerable time in the greatest suspense, owing to some accidental circumstance having put the candle out before it reaches the pot-hole, when they are fearful of venturing, from the uncertainty of what may be the event. In many instances it has been found necessary to explode these lodgments three times a day, at each time clearing the mines of all the workmen except the firemen; the necessity of which has been occasioned by the miners cutting down strata or measures of coal, so as to render the roof higher than the general run, of six or eight feet seams, and by these means making the extra elevation too great to be effected by the diluting current.

In fact, where the roof of a coal mine (where the seam is thirty-six feet thick,) is cut down, no means but the firing process could suspend for a single day the destructive effects produced by an explosion of the whole mine. To obviate the dangers and difficulties of the firing process, Mr. James Ryan, of Netherton colliery, near Durham, who had been for many years engaged in working mines, invented, in lieu of it, a simple, effectual, and economical system of ventilation, by which the fire-damp, or inflammable gas, was carried off upwards from the mine, whilst by another arrangement he caused the carbonic acid gas (or choke-damp) to pass off into the water level. In attempting to get his plans of ventilation tried at various mines, he met with the most stubborn opposition; and although in every instance in which he was allowed to introduce his system, he was eminently successful, yet, from the misrepresentations of ignorance and jealousy, his system of ventilation has been adopted in very few mines, and the firing process is still very generally resorted to. Mr. Wood, of Summer Hill Grove, Northumberland, has however invented an apparatus by which the firing may be effected without any personal danger.

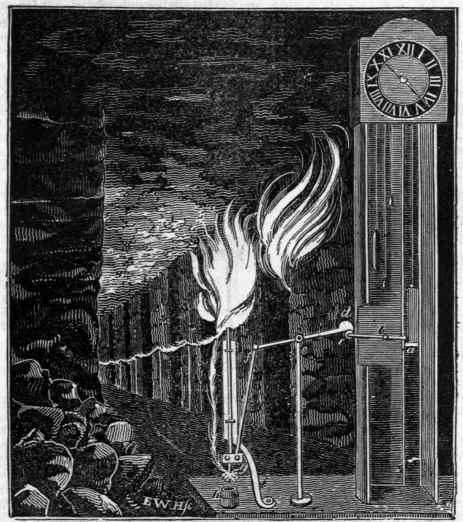

The annexed diagram represents the interior of a coal mine in perspective, with Mr. Wood's apparatus employed in igniting the gas. It consists of a common Dutch striking clock, in which the descent of a weight at a previously determined hour raises a lever having a counterbalance weight: this lever acting upon another lever, causes a match, charged with oxymuriate of potash, to be dipped into a bottle containing sulphuric acid; the counterbalance weight on the first lever immediately afterwards draws the match out of the bottle, when the contact of the air causes the match to ignite, and to set fire to a train of combustible matter connected with it, consisting of cotton or tow saturated with spirits of turpentine, a represents the weight of the clock, which is set to go off at the time denoted; a projecting piece at the bottom of the weight presses in its descent upon one extremity of a lever, which turns upon a fulcrum at b: the other end of this lever is provided with a roller c, which raises the loaded end d of another lever, supported upon a standard at e; at f is a rod attached by a joint to the other extremity of the second lever, and at the lower end it is jointed to a small block, to which is fixed the match.

To the match are attached some loosely twisted filaments of cotton, which are carried upward, and wound round an iron rod as loosely as possible, so as to form a large bunch of easily ignitable matter, to further which the whole is saturated with spirits of turpentine: the iron rod containing the bunch of cotton slides up and down in a fixed standard i, as represented; and from this point a train is made to other parts of the mine, where the inflammable gas may have collected in a detached volume, by means of strips of brown paper dipped in oil of turpentine, which are strung together and suspended in festoons on standards fixed in the ground. The clock being set to go off when all the workmen are absent from the mine or at rest, the weight operates upon the lever at the precise period determined upon, ignites the match and the train, and thus destroys all the inflammable gas.

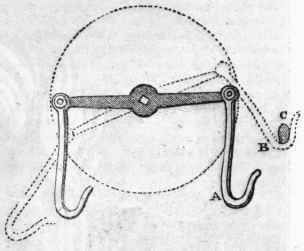

The following is a simple and useful contrivance for the prevention of accidents in raising men or minerals out of mines, by the ropes " running wild," as it is termed, and for which the inventor, Mr. E. Speers, was presented with the silver Vulcan medal by the Society of Arts. A bar is fixed on the end of an axis. Two hooks, as A, swing freely on the ends of this bar; C is a short bar or stop, projecting from the frame of the machine, for the hook to catch hold of. When the bar revolves at a moderate rate, the hooks constantly hang down by their own weight, and keep clear of the stop C; but when it revolves with a dangerous rapidity, the centrifugal force causes the hooks to diverge from their pendant position, and one of them catches hold of the check-bar C, (as shown by dotted lines,) which stops the machine instantly.

A correspondent in the Register of Arts proposes the following modification of this contrivance, by which the shock occasioned by the sudden stoppage of the- machinery is avoided, and the further advantage gained, that when the velocity of the machinery is so far reduced as to avoid danger, the machinery will hot stop, but will recommence motion of itself. In the engraving in the next page, a is a section of Mr. Speers' check-hooks; the bar to which the hooks are suspended turns with the axle be; e is a conical pulley, with grooves cut in a spiral direction, as represented in the section; this pulley turns on the axle, and not with it, like the bar a; out of this pulley projects the check-pin f. G is a screw fixed to the frame h, which fits into the pulley e, so as to enter it as soon as the pulley is made to revolve in the same direction as the bar a, i is a cord fixed to the pulley e, so as to be wound round all the grooves when the pulley is turned; to the end of it is fixed a weight, the size of which must be regulated according to the velocity with which the machine is required to work.

From inspection of the plan it will be seen that when the check-hooks, by the too rapid revolution of the check-bar a, have diverged so far from their pendant position as to lay hold of the check-pin f, the pulley e will be drawn round in the same direction as the bar a, and will wind the weight suspended by the cord i until the cord reaches the uppermost groove, as at l, when the velocity of the machinery will be greatly moderated, at which time the pulley e will have advanced so far along the screw G as to draw the check-pin out of the check-hooks, when the machinery will proceed in a regular way, and the cord i, by the descent of the weight attached to it, will reverse the motion of the pulley, and return it to its original position, as shown at i, where it will be always ready to regulate the machinery when the check-hooks, by their centrifugal force, come in contact with the check-pin f.

Continue to: