Second Railway Era. Part 7

Description

This section is from the book "The Engineer's And Mechanic's Encyclopaedia", by Luke Hebert. Also available from Amazon: Engineer's And Mechanic's Encyclopaedia.

Second Railway Era. Part 7

It is a remarkable fact in the history of our iron manufacture, that at so advanced a period as 1817 no attempt had been made to make railway bars of malleable iron of a judicious form, like those used in the cast metal. It would seem that the manufacturers of that time imagined that their grandfathers had taught them all that it was possible to acquire in their art of rolling bars; that it was too wild an attempt to make any other form than cylindrical and rectangular, although they might obviously effect the required configuration by the same tools and machinery, with merely a slight deviation in the form of the grooves. In consequence the proprietors of the railways and coal-works went on breaking their cast iron and bending their weakly shaped malleable bars, incurring for three years afterwards very serious accidents and loss. At length Mr. John Birkenshaw, of Bedlington, made the notable discovery we have just alluded to, (and which we should have thought would have been obvious to everybody,) of making the grooves of the shape desired.

He took out a patent for his invention in 1820, and made, it is said, a considerable fortune by it; his specification we will now make an extract from: -

"My invention consists in the adaptation of wrought or malleable iron bars or rails of a peculiar form, instead of cast iron rails, as heretofore. From the brittle nature of cast iron, it has been found, by experience, necessary to make the bars of a railroad sufficiently-strong to bear at least six times the weight intended to be carried along the road, by which the original cost of a railroad was considerably augmented; or if light rails were used, the necessity of frequently repairing entailed a very heavy expense upon the proprietors. To obviate these objections, I have invented a bar to be made of wrought, or malleable iron, the original cost of which will be less than the ordinary cast iron rails or bars, and, at the same time, will be found to require little (if any) reparation in the course of many years. The rails or bars which I have invented are formed as prisms, though their sides need not of necessity be flat. Figs. 1 and 2 show sections of the bar thus formed; the upper surface upon which the wheel of the carriage is to run is slightly convex, in order to reduce the friction; and the under part rests in the supporting-blocks, chairs, rests, standards, or pedestals, which are mounted upon the sleepers.

The wedge-form is proposed, because the strength of the rail is always in proportion to the square of its breadth and depth. Hence this form possesses all the strength of a cube equal to its square, with only half the quantity of metal, and, consequently, half the cost. Sufficient strength, however, may be still retained, and the weight of metal further reduced, by forming the bars with concave sides, as shown in section, by Figs. 3 and 4."

Fig.1.

Fig. 2.

Fig. 3.

Fig. 4.

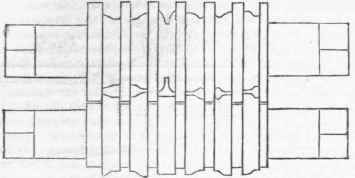

The rolls made use of by Mr. Birkenshaw are exhibited in the annexed figure, which represents an elevation or side view of a pair of them. It will be observed that the circumference of each roll is indented by a series of grooves; each groove in the upper roll corresponding in shape with those of the lower roll, excepting in one case. Consequently the figures described by the hollow spaces between each roll, represent the form of the bars to be made.

It will therefore be obvious, that when a red-hot bar of iron is applied to the grooves of such rollers, forced round by a powerful steam-engine with great velocity, the iron will be compressed into the same form throughout its length.

The form of rail now most approved of, which we shall have occasion hereafter to describe, is made by the same kind of machinery.

The annexed wood engraving is designed to show Mr. Birkenshaw's railway, the kind of waggons used, and the nature of the power at that time in general use. The superiority of Mr. Birkenshaw's rail over that in general used previously, which was the joint invention of Messrs. Stephenson and Losh, excited the rivalry of the latter gentleman; accordingly we find him taking out another patent for "certain improvements in the construction of iron rails for railroads," which being to us very doubtful, we shall describe it very briefly.in his own words: - "First, in using, placing, and fixing bars of malleable iron on the upper surface of a line of cast iron rails or malleable iron rails, of whatever form such rails may be in the longitudinal direction of the rails when laid, so as to form an uninterrupted line the whole length of the bar, which may be as long as it shall be found convenient and economical to use, and of the same breadth as the upper surface of the rails to which it is fixed, or a little broader or narrower.

Secondly, in some cases I fix a band or strap of malleable iron to the under surface of rails made of cast iron, in order that such band or strap may, by its power of tension, give support to the cohesion of the parts of the cast iron rails, and admit of its being made lighter, and thus save expense, while it adds to security from breakage. Thirdly, I claim as an improvement, a rail formed by fixing two bars of malleable iron on their sides or edges, and fixing them in that position by bolts and studs, or by any other convenient method; and on their upper edges placing and fixing a flat bar of malleable iron, or one which is slightly curved or rounded at the edges to diminish friction, so that the bar or plate, placed and fixed on the upper edges of the two malleable iron bars, shall form the surface upon which the wheels of the waggon or carriage are to revolve." After this statement, we think the practical reader will not be disappointed if we omit the details of construction.

Continue to: