Miscellaneous Joints

Description

This section is from the book "Spons' Mechanics' Own Book: A Manual For Handicraftsmen And Amateurs", by Edward Spon. Also available from Amazon: Spons' Mechanics' Own Book.

Miscellaneous Joints

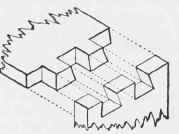

Among the miscellaneous joints in carpentry not previously mentioned, the most common are the butt-joint, Fig. 503, where the pieces meet each other with square ends or sides; the mitre-joint, Fig. 504, where the pieces abut against each other with bevelled ends, bisecting the angle between them, as in the case of struts mitred to a corbel piece supporting the beam of a gantry; and the rabbeted or " rebated " joint, Fig. 505, which is a kind of narrow halving, either transverse or longitudinal. To these must be added in joinery the grooved and tongued joint, Fig. 506; the matched and beaded joint, Fig. 507; the dowelled joint, Fig. 508; the dovetailed joint, Fig. 509; and other modifications of these to suit special purposes. To one of these it may be desirable to call particular attention, viz. the flooring laid folding. This is a method of obtaining close joints without the use of a cramp. It consists of nailing down 2 boards, and leaving a space between them rather less than the width of, say 5 boards; these 5 boards are then put in place, and the two projecting edges are forced down by laying a plank across them, and standing on it. This may generally be detected in old floors by observing that several heading joints come in one line, instead of breaking joint with each other.

It is worthy of notice that the tongue, or slip feather, shown in Fig. 50G, which in good work is formed generally of hard wood, is made up of short pieces cut diagonally across the grain of the plank, in order that any movement of the joints may not split the tongue, which would inevitably occur if it were cut longitudinally from the plank.

Continue to: