Saws. Part 6

Description

This section is from the book "Spons' Mechanics' Own Book: A Manual For Handicraftsmen And Amateurs", by Edward Spon. Also available from Amazon: Spons' Mechanics' Own Book.

Saws. Part 6

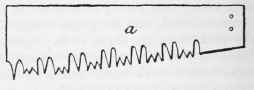

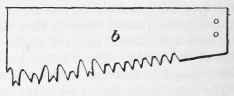

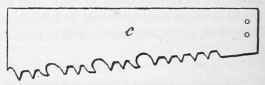

The chief facts to be borne in mind in selecting a saw with the teeth best suited to the work in hand are the nature and condition of the wood to be operated on. No fixed rule can, however, be laid down, and the user must be guided by circumstances. All saws should be ground thinner towards the back, as less set is thus necessary, the friction on the blade is reduced, and the clearance for sawdust is improved. Care should also be taken that they are perfectly true and uniform in toothing and temper. The angle of the point of a tooth can be found by subtracting its back angle from its front, and to do the best and cleanest work this angle should be uniform in all the teeth of the saw." (M. Powis Bale, M.I.M.E., A.M.I.C.E.)

The following table includes saws generally used by mechanics who work wood by hand: -

Names. | Length in Inches. | Breadth in Inches. | Thickness in Inches. | Teeth to the Inch. | |

At Handle. | At End. | ||||

Without Backs. | |||||

Rip-saw........ | 28-30 | 7 -9 | 3 -4 | 0.05 | 3 1/2 |

Fine rip-saw.......... | 26-2S | 6 -8 | 3 -3 1/2 | 0.042 | 4 |

Hand-saw.......... | 22-24 | 5 -7 1/2 | 2 1/2-3 | 0.042 | 5 |

Cut-off saw.......... | 22-24 | 5 -7 1/2 | 2 1/2-3 | 0.042 | 6 |

Panel-saw......... | 20-24 | 4 1/2-7 1/2 | 2 -21/2 | 0.042 | 7 |

Fine panel-saw........ | 20-24 | 4 -6 | 2 -2 1/2 | 0.035 | 8 |

Siding-saw........... | 10-20 | 2 1/2-3 1/2 | 11-2 | 0.032 | 6-12 |

Table-saw.......... | 18-26 | 1 3/4 - 2 1/4 | 1 - 1 1/2 | .. | 7-8 |

Compass or lock-saw | 8-18 | 1 -1 1/2 | 1/2 - 3/4 | .. | 8-9 |

Keyhole or pad-saw...... | 6-12 | 1/2-3/4 | 1/8-1/4 | .. | 9-10 |

With Backs. | |||||

Tenon-saw.......... | 16-20 | 3 1/4-4 1/4 | 0.032 | 10 | |

Sash-saw.......... | 14-16 | 2 1/2-3 1/2 | 0.028 | 11 | |

Carcass-saw........... | 10-14 | 2 -3 | 0.025 | 12 | |

Dovetail-saw........... | 6-10 | 1 1/2-2 | 0.022 | 14-18 | |

(Holtzapfel.)

Continue to: