203. Hot-Drawn Seamless Tubes

Description

This section is from the book "An Elementary Outline Of Mechanical Processes", by G. W. Danforth. Also available from Amazon: An elementary outline of mechanical processes.

203. Hot-Drawn Seamless Tubes

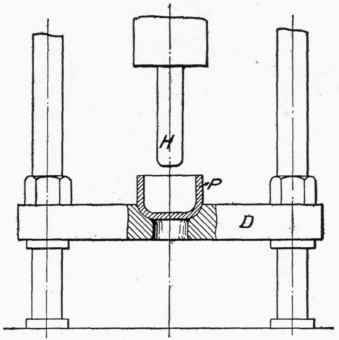

For producing seamless tubes larger than 6 inches outside diameter, a hot drawing process is used. In this process a plate of the required thickness is punched or sheared into a circular disc. This disc is then heated to a bright red heat and placed in a hydraulic press arranged as in Fig. 75. The disc P is placed over the circular opening in the die block D of the press, and the plunger H is forced down on the plate, carrying it completely through the opening in the die block. The difference in the diameters of the openings of the die block D and the plunger H is such as to give the sides of the cup the thickness of the disc. The squeeze between the plunger and the die block, as the disc passes through, presses the sides of the cup free from wrinkles. This operation is repeated with or without reheating until a cup is produced of considerable length. The form of the die used in the succeeding operation is shown in Fig. 76. The die is recessed to receive and locate the cup produced by the previous operation and frequently the bottom of the cup is cooled by water to keep the plunger from punching a hole through it.

Fig. 76. - Making Hot-Drawn Tubes. Re-Drawing Cupped Discs.

Fig. 77. - Cupped Discs.

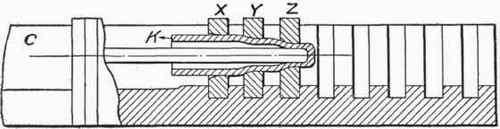

The plate after receiving one or more cupping operations in vertical presses, is in a cupped form as shown in Fig. 77. Each cup is reheated and transferred for further reduction to a horizontal press usually called a hot-drawing bench, the essential features of which are shown in Figs. 78 and 79. The bench consists of a heavy frame placed horizontally and connected to a hydraulic cylinder C. In operating, the cup K is placed over the end of the plunger rod, which is arranged to travel the entire length of the bench frame.

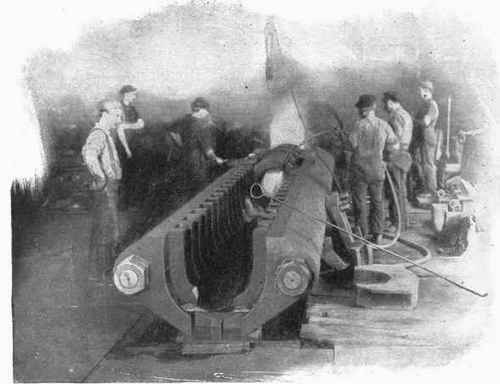

Fig. 78. - Hot-Draw Bench for Elongating Cupped Discs.

Dies X, Y and Z, with openings of successively smaller diameters, are placed in suitable holders in the bench frame. The cup K is pushed through the dies successively as shown in the figure, reducing the diameters and the wall thickness. Several drawings are made in this manner, reheating between each operation until the tube is reduced to its final diameter and wall thickness. The bottom of the cup is cooled with water from a hose to keep the plunger rod from punching a hole through it while the cup is passing through the dies.

Fig. 79. - Hot-Draw Bench.

After reducing the tube to its final diameter, the bottom is sawed off, the ragged edges of the open end are trimmed off, and the tube is then inspected and tested under hydrostatic pressure.

To show the change of form possible in hot drawing, a tube 22 feet long 9 1/4 inches inside and 10 inches outside diameter is made from a round plate 54 inches in diameter and 1% inches thick. This requires ten passes through as many different-sized dies.

Hot-drawn tubes may be further cold drawn to produce tubes up to ten inches in diameter.

Continue to: