Microphones. Part 3

Description

This section is from the book "American Library Edition Of Workshop Receipts", by Ernest Spon. Also available from Amazon: American Library Edition Of Workshop Receipts.

Microphones. Part 3

Having con nected your batteries and telephones, bring the feet of the magnet within J in. of the iron wire (the wire must not touch the magnet). Now speak, standing 3 or 4 ft. away - your friend will then report to you through the telephone the result; if not satisfactory, move the magnet farther away, until the voice is clearly heard, and in its natural tone. The results are equally as satisfactory as wonderful, the magnet merely acting as an easily adjustable spring in controlling superfluous vibration, which is the cause of that peculiar and annoying jarring sound. (R. Blakeborough.)

Fig. 89.

(5) Get a thin bit of board about 6 in. by 3 in., supported at each corner by little feet, also 2 small blocks of carbon with a hole through the middle and a notch at the side of each; screw them into the board about 1 1/2 in. apart by binding - screws, and across them, resting in the notches, put a bar of carbon; it will much improve it if the carbon is heated red - hot and plunged into mercury. The microphone is now complete. To connect it, join one terminal of microphone with one pole of the battery and the other with one pole of the telephone; the second terminal of the telephone is joined with the other of the battery. (E. H. Hills.)

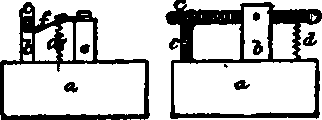

(6) The following arrangement of microphone transmits speech clearly. The sketches are sectional (Fig. 90).

Fig. 90.

a, side of box; b, one of 2 pieces of copper between which the horizontal piece of pencil carbon c is spindled so that one end rests lightly on the other piece of pencil carbon c, which is fixed upright; b, the 2 pieces of copper mentioned before; c, end of the horizontal piece of carbon, under which a fine watch - spring f passes. One end of the spring f is screwed on to a wooden block e, The pressure of the spring f against the end of the carbon c is regulated by the screw d, which passes through it. Use a Bell's telephone as the receiving instrument. Speak in a low clear tone quite close to the microphone, and if the voice cannot be heard well at the other end of the line, tighten the screw d, thereby easing the pressure of the spring / against the carbon c. On the other hand, if too much vibration is heard, loosen d a little. Use either a small bichromate battery, or a single No. 2 Leclanche cell. {Eng. Mech.)

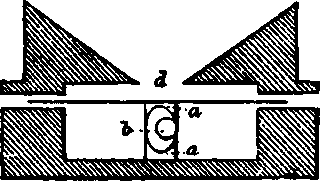

(7) Cup - and - ball microphone (Fig. 91). To construct the cup - and - ball microphone, take the case of an ordinary Bell telephone, remove the magnet and coil, cut off the long end or handle which contained the magnet, and plug up the hole in the case; turn the 2 cups out of a piece of a round carbon rod 3/8 in. in diameter, and make the ball out of a piece of round carbon rod 3/16 in. diameter. Secure one of the cups to the centre of the wooden case of the telephone by a small screw, and the other cup to the centre of the diaphragm of the telephone by a leaden rivet; place the carbon ball in the cup which is secured to the case, and place the diaphragm with the cup attached to it in its former position in the telephone case, having of course first carried a wire from each carbon cup to a terminal screw; see that the 2 cups are concentric; screw in the mouthpiece, and the microphone is complete. The microphone must be mounted in gimbals like a looking - glass, and slightly inclined backward or forward, until it speaks quite clearly, when it may be clamped.

Each microphone has one position in which it speaks best, and this position must be found by actual trial, If the microphone is intended for ordinary use, the diaphragm should be made of thin deal, straight - grained and about 1/8 in. thick; after the carbon cup is attached, the wooden diaphragm should receive, in the side against which you speak, a coat of thin white hard varnish, put on in a dry room with a wide brush.

Fig. 91.

In the sketch, a are the carbon cups, b is the carbon pea, d is the diaphragm, and the shaded parts represent the telephone case, which, as drawn, is not closely screwed up. The open interior part of the case, i.e. the part which determines the area of the free vibrating portion of the diaphragm, should be 2} in. in diameter; the other dimensions may be varied according to fancy, but the carbon cup attached to the diaphragm should not be more than about 1/4 in. in length. There is no difficulty in turning the carbon cups, the only tools required being a brad - awl, which makes a capital drill for carbon; an old file to smooth down the back and face of the cup, which can, however, be done with emery - paper; the stump of any old small chisel ground to a long cutting slope; and a fret - saw. It is desirable to turn a small piece of boxwood to such a shape as will fit into the cup when completed, and by pushing this lightly into the cup whilst it is running in the lathe, the interior of the cup will be smoothed, and in many cases polished.

To make the ball, chuck a piece of 3/16 in. round carbon rod, and at the end turn a round head, like the head of a pawn in a set of chessmen; get it as nearly round as possible - a file is the best tool for this - and then cut it off; rub off any projections on emery - paper. The remainder of the process may be done in 2 ways. (1) Tack a sheet of emery - paper on a board, secure another piece of emery - paper to a conveniently - shaped piece of wood with a flat face; put the carbon pea on the emery - paper tacked on the board, and, with the other piece of emery - paper - covered wood, rub the pea about in every direction between the two, and with a little care the pea will become nearly a true sphere. (2) The other way, advised by Yeates, of King Street, Covent Garden, is - take a piece of sheet - steel about as thick as a screw - blade, and about 2 in. long by f in. wide, soften it, chuck it by means of sealing - wax; drill a hole, about. 1/8 in. in diameter, through the centre - the exact centre is not required; then with a very keen' edged tool enlarge this hole to about 5/32 in. diameter, and take care that the , edges of this hole are left sharp and not rounded; then harden the plate as hard as you can make it.

Continue to: