Plaster Casting. Part 6

Description

This section is from the book "American Library Edition Of Workshop Receipts", by Ernest Spon. Also available from Amazon: American Library Edition Of Workshop Receipts.

Plaster Casting. Part 6

In the usual casting operations it is generally necessary that the mould in which the casting is made should be of less fusibility than the material cast, although there are rare cases in which this does not hold good; but in the case of the striking method just described, we have a method by which an impression may be obtained in a much more refractory material than the original matrix. For example, an impression in sealing wax taken from type may be quickly driven down on the surface of type-metal just on the point of commencing to solidify, and will yield a perfect cast in the alloy, e.g., by means of the quick screw-press before used. Similarly, a die in high steel may be made from a silver or copper coin, if the steel is heated to bright whiteness, and the coin, attached to a drop-hammer, is allowed to fall upon it. The main points to ensure success appear to be forming of the steel block as a blunt cone, so that the middle shall first come in contact with the original, and the protection of the hot steel from the action of the air till the last instant.

Dies made by this process are sometimes so perfect as to recall the smoothness and perfection of an electrotype; and it is no uncommon thing for mints to send coins in order to obtain fresh dies for the replacing of injured ones. The method of moulding by striking into soft metal is of great value, and those interested in methods of typographic reproduction should bear in mind the possibilities of this method. If, for example, numerous small stereotypes in hardened steel were required, they could readily be obtained by the "striking " method, a steel die (itself, let us suppose, "struck " from an electrotype) being used.

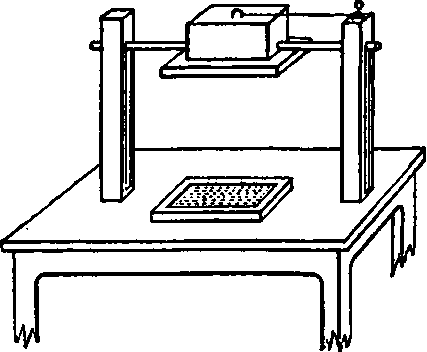

Early polytype apparatus.

Very much of interest and importance arose out of experiments carried on in the office of Firm in Didot, in Paris, about the end of the last century and the beginning of this. In the first place, the introduction of a hard type-metal containing copper, this being due to Herhan, at the time a workman in the employment of Didot, and the hard metal was introduced to enable the type to stand the strain1 of moulding by dead pressure against lead plates. One of Herhan's alloys contained: - Lead, 25 parts; antimony, 15; copper, 6.

Another notable outcome of the work in Didot's office was the production of a matrix by punching the letters into it successively, a device of Guillot, another workman in the service of Didot. Guillot called his process "grapbitype," and he drove the steel type-punches successively into a copper plate, this plate being then used as a matrix for casting a stereotype. Guillot's method may be regarded not only as the parent of the various "type-writer " methods of making matrix sheets or strips, but also of Herhan's next introduction - the use of matrix types.

It is easy enough to' illustrate the principle of Guillot's " graphitype " by driving punches into the face of a copper plate, using a guide rule to keep the line, and then casting from the plate in the usual casting-box. In this form, however, it is hardly a practicable method, but its modern developments, in which a kind of type-writer is used to make a matrix out of wood (the end of the grain) or soft paper, may perhaps come into general use.

Herhan, whose hard metal has just been referred to, developed the idea of his fellow workman, and made it more practicable by setting up the page with matrix types instead of driving the punches into a plate of copper, this arrangement allowing corrections to be made, and also ensuring that the whole of the printing surface shall be in one plane. Herhan's types were of brass or copper, and generally similar to the ordinary types, but in place of the projecting or male letter of our ordinary type, was* a female or matrix letter, just the reverse of the face of the usual type. Such letters are set just as ordinary types, excepting that they are arranged in the stick and chase non-reversed, and a proof can be taken on the press; preferably, however, on thin paper, such as is used for copying letters, as the impression must be read through the paper if it is to be read non-reversed. Another way of taking a proof is to lay a sheet of plain paper on the " forme," and over this a sheet of black manifold paper, the coating of which sets off on the plain paper when the pressure is applied.

The "forme " being locked up, and any large whites overlaid with special quadrats (or high quadrats may be used in the first instance), it is shut up in a casting-box, and the stereotype is made directly from it. Didot issued several books printed from stereotypes made by this method.

The "linotype" system of Mergen-thaler, in which a very cleverly designed machine brings a number of matrices into a row, so that a line is cast, may be regarded as in some sense a development of the idea of Herhan.

Considering that, in the case of newspaper work, printing is always done from stereotypes, it seems to me that it would be a more reasonable and direct proceeding to set the matrices, and cast the required plate directly into the matrix forme, rather than to delay matters by the intermediate process of moulding. Although Herhan devised excellent methods of striking his matrix type quickly, and in true register, from the original-punches, an engineer of the present day could do better: he could design a machine which would turn out brass or copper matrix types about as quickly as wire nails are cut off and headed, and the cost per lb. of the matrix type possibly might not exceed that of ordinary types. Again, it is quite easy to make the matrix types radial, so that they can be "made up" in curved boxes, and plates for rotary machines cast as soon as the last lines are set or the final corrections made. 1 cannot help thinking that the time is not far distant when Herhan's matrix types will largely replace those used now, and it need scarcely be said that the ordinary typesetting and distributing machines would be as available with these as with the sort of type now in use.

It certainly seems absurd to set a " forme," and mould a matrix from it when it is just as easy to set up the matrix, and to cast directly into it.

The plaster process of stereotyping was now established, and soon came into very general use for certain classes of work, and the next great step was the paper process, in which softened paper is forced down upon the original type " forme," and in the mould thus obtained one cast or more can be made. This has become essentially the stereotyping method, and has ousted all other processes, except for special work. Among other things, it has rendered possible the modern newspaper; and the facility which it affords for rapidly producing any required number of curved plates, suited for rotary machines, has revolutionised printing as far as rapid production is concerned. Moreover, the process is so simple and to easy that any person may, for a cost of a few shillings, produce small stereotype plates equal in sharpness and general excellence with those made in the most perfectly fitted establishment.

The essential principles of the paper-mould method are as follows: - On a pad of soft paper, built up of about 20 thicknesses of soft blotting-paper, stapled together at the edges, a hard impression from a page of type is taken. It is now placed between two slabs of dry wood, which slabs are separated to a distance of something under 1/4 in. by strips of the same material, and melted type-metal is poured in at the top. On separating the slabs of wood you have a fairly good cast of the original type, and the whole process of producing it has taken less than a minute. In practice, however, dry paper is not used for making the mould, but a number of sheets are pasted together, and this combination is used damp. .

The soft pasteboard ready made is known to the workman as "flong," a corruption of flan, a thin farinaceous cake sold in Paris. This is laid on a warm and slightly oiled page of type, and the back is beaten with a stiff brush until the soft pasteboard has taken a perfect impression of the face of the type. On the back now lay a piece of blanket, pinch the whole in a screw press, the press having been previously warmed. The drying of the mould may, under such circumstances, take from a few minutes to 1/2 an hour, according to the temperature and the frequency with which the blanket and other packing is changed. Being clamped between slabs of warm iron, metal is poured in, and a cast is obtained, little if at all inferior to the original type in sharpness. Here you have the essential features of the paper-mould process, the most important of all stereotyping processes.

Continue to: