Construction And Management Of Gasoline Engines. XI. Installiing Engines-Under Water Exhaust

Description

This section is from the book "Amateur Work Magazine Vol6". Also available from Amazon: Amateur Work.

Construction And Management Of Gasoline Engines. XI. Installiing Engines-Under Water Exhaust

Carl H. Clark

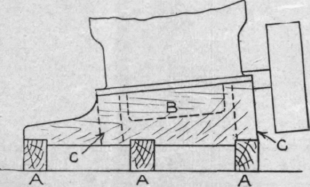

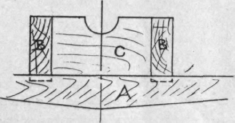

The first question in the installation of the engine will be the bed, or foundation. Fig. 74 shows one of. the most approved methods of construction, the bed. The two side pieces B, upon which the flanges of the engine bed rest, in turn rest upon the cross pieces A. These cross pieces A are built into the boat and distribute the strain. The side pieces B are notched down over the cross floors A and through fastened. A center piece C is worked in between the side pieces A whenever convenient to prevent their rocking sidewise. The whole is then firmly secured together and to the hull.

Small engines may be supported upon a single cross piece at each end of the bed, but except for the smallest sizes the arrangement of Fig. 74 should be used. The engine is fastened down to the bed with lag screw.

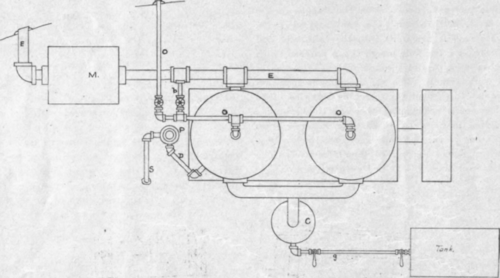

The heaviest, and in most cases the hardest, pipe to fit up is the exhaust pipe. It runs from the exhaust nozzle on the engine to the muffler and thence outboard. Fig. 75 shows a diagram of the piping as usually arranged. The muffler M is commonly placed in the stern with the outlet directly outboard It may, however, be placed in any convenient position as under the seats in the standing room, and the piping lead outboard. In any case, the piping for the exhaust should be as direct and as free from sharp bends as possible.

When the motor is near the middle of the boat, a good practice is to lead the exhaust pipe out through the bottom, along the bottom to a point near the stern, where it again enters the boat and connects with the muffler. The outlet from the muffler then leads directly outboard as before. This method, especially on a large cabin boat, avoids much loss of space and the disagreeable heat of the exhaust pipe. The surrounding water quickly cools the exhaust, reduces the pressure, and makes the exhaust almost noisless.

The particular function of the muffler is to afford a comparatively large space into which the exhaust may pass and expand, greatly reducing the pressure. The gas, under the reduced pressure, then passes out with little disturbance. The muffler need be of no particular shape, as long as the volume is sufficient. Mufflers are usually made of cast iron in the smaller sizes and of sheet iron in the larger sizes. In many cases a long piece of rather large pipe will answer the same purpose.

The muffler may be dispensed with and much space saved by carrying the exhaust directly through the bottom of the boat and exhausting under water. Although this is a very convenient and many times satisfactory way of doing it, great care must be used or poor results will be obtained. When the exhaust leads directly out, a certain amount of pressure is used in displacing the water. This pressure is, of course, supplied by the piston and is a back pressure, as it is turned, retarding the piston and decreasing its power.

Fig. 74.

A small expansion chamber or muffler should be provided between the engine and the outlet in order to break up the violent pulsations and make the flow fairly constant. Some form of shield should be fitted over the outer end of the exhaust pipe to guide the stream of the exhaust aft and prevent the water being forced into it by the movement of the boat. Several forms of these are on the market in the form of a brass casting which bolts on to the outside of the hull and has a thread on the inside to take the exhaust pipe.

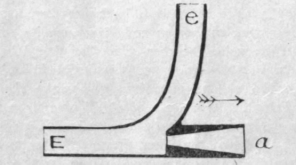

One of the best of those is on the principle shown in Fig. 76. The exhaust passes from the engine to e and out at E, the passage being curved in an easy bend. At a is a funnel shaped passage opening into the exhaust passage. The motion of the boat is assumed to be toward the right; the water will be forced into the opening a and out through its small end, at a considerable velocity, mingling with the stream of exhaust gases and tending to accelerate their How. This principle tends to lessen the back pressure on the engine, and may, under some circumstances, entirely do away with it.

The under water exhaust is a very neat and simple method when corrently installed, as all noise and heat from the exhaust pipe are aoided. The exhaust may be considerably cooled and the noise reduced by discharging the cooling water from the cylinders directly into the exhaust pipe as shown in Fig. 75 and explained more in detail later. All sharp bends must be avoided in the exhaust pipe as the resistance offered by them is equivelent to back pressure and reduces the power of the engine.

When the under water exhaust is fitted, a pet cock should be put in the exhaust pipe near the engine. This is opened when the engine is stopped, thus preventing the water from being drawn up into the cylinders by the vacuum caused by the cooling of the gasses in the pipe and cylinders.

The water piping of brass pipe is next to be fitted. The connection to the suction S of the pump P should be piped down through the bottom of the boat at some convenient point. This pipe may be made up solid, although many people fit a short length of rubber hose at a convenient point to take up the vibration of the engine and prevent the starting of the joints where the pipe passes through the hull. The outer end of this pipe is covered with some kind of strainer to filter out weeds, etc. A special casting is usually furnished including a clamp for both inside and outside of planking and a thread for the end of the connecting pipe. Care must be taken where this pipe passes through the planking, to get a good joint or leakage will ensue. In small engines the entire water piping may conveniently be of rubber hose. It is advisable to fit a valve on the pipe just inside the hull, by closing which, all possibility of flooding the boat will be avoided.

Fig. 75.

Fig. 76.

When the exhaust pipe is run under the floor a pet cock should be fitted at its lowest point, to drain off any condensation or collection of moisture. The discharge from the muffler should pass out through the side of the boat well above the water line, so that there will be little chance of its becoming submerged and flooding the muffler. When the engine is working there will, of course, be no chance for the water to pass in against the exhaust pressure, but if the boat were moored there might be a possibility of such an occurrence.

Continue to: