Home-Made Hand Drill

Description

This section is from the book "The Boy Mechanic Vol. 1", by Popular Mechanics Co.. Also available from Amazon: 700 Things for Boys to Do.

Home-Made Hand Drill

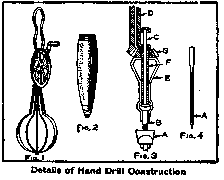

In the old kitchen tool box I found a rusty egg beater of the type shown in Fig. 1. A shoemaker friend donated a pegging awl, Fig. 2, discarded by him due to a broken handle. With these two pieces of apparatus I made a hand drill for light work in wood or metal. By referring to Fig. 3 the chuck, A, with stem, B, were taken from the awl. The long wire beater was taken from the beater frame and a wire nail, 0, soldered to the frame, D, in the place of the wire. The flat arms were cut off and shaped as shown by E. The hole in the small gear, G, was drilled out and a tube, F, fitted and soldered to both the gear and the arms E. This tube, with the gear and arms, was slipped over the nail, 0, then a washer and, after cutting to the proper length the nail was riveted to make a loose yet neat fit for the small gear. The hand drill was then completed by soldering the stem, B, of the chuck to the ends of the flat arms E. Drills were made by breaking off sewing-machine needles above the eye as shown in Fig. 4 at A, and the end ground to a drill point. --Contributed by R. B. J., Shippensburg, Pa.

Details of Hand Drill Construction

Drill Lubricant

A good lubricant for drilling is made by dissolving 3/4 to 1 lb. of sal-soda in one pailful of water.

Substitute For A Drill Bit

A gouge may be used as a substitute bit if a proper sized bit is not at hand. The gouge can be placed in the brace the same as a bit.

Continue to:

More:

- Fourth-Of-July Catapult

- Hollow-Grinding Ice Skates

- An Austrian Top

- Rolling Uphill Illusion

- How To Make An Inexpensive Wooden Fan

- How To Make A Self-Setting Rabbit Trap