German Continuous Carbonating Apparatus. Part 2

Description

This section is from the book "A Treatise On Beverages or The Complete Practical Bottler", by Charles Herman Sulz. Also available from Amazon: A Treatise On Beverages.

German Continuous Carbonating Apparatus. Part 2

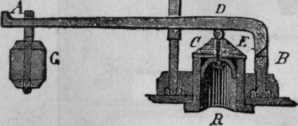

Fig. 115. - Safety Valve.

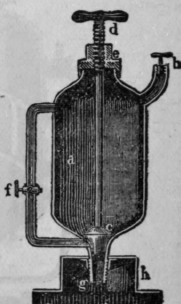

Fig. 116. - Mixer for Salt Solutions.

In many German establishments they frequently add to a full set of continuous apparatus more facilities for the purification of gas in addition to the ordinary purifiers. The following illustration shows some arrangement of the kind:

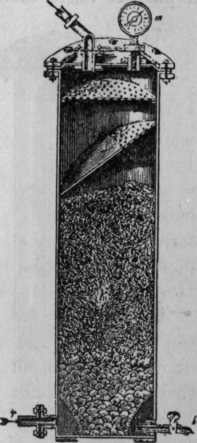

This repurgator or purifying cylinder is generally adjusted between pump and condenser. It is intended to purify the gas from all fatty stuffs which it might carry along when passing the greased valves and pumps (the modern apparatus however are so arranged that the passing carbonic acid gas is protected against any contact with the greased parts of an apparatus), but more especially the re-purgator is intended to purify the carbonic acid from any bad odor, contaminating gases, that it might be adulterated with, arising from impure carbonates, and not having been thoroughly absorbed by the purifiers through which the gas has already passed. This means when the gas alone passes as in the semi-continuous process; but the repurgator is equally and usefully employed in the continuous process, when both gas and water combined will pass through it and become purified. The repurgator is a cylinder of copper, tin-lined inside, a few feet in height. Near the bottom it has two openings, r for the entrance of the gas from the pump as the gas passes upwards, h with cock to let remaining gas escape if necessary. The semi-globular cover, with a rubber sheet between, is air tight, secured to the repurgator by bolts. It has two openings too, one a to lead the carbonic acid gas to the condenser, the other m for the pressure-gauge (although not absolutely necessary). The cylinder is every month to three fourths of its height filled with charcoal, carefully prepared of pine wood. The wood coal is crushed to small fragments of the size of an ordinary bean, the dust carefully sieved off. At the lower part of the repurgator is first a layer of larger coal-pieces.

To prevent the pipes at the bottom from getting clogged up, they are protected by a sieve; and to prevent the stream of carbonic acid gas and water from carrying over any coal particles into the condenser, there are above the surface of the coal one horizontal and one oblique sieve of a conical form, made of tinned copper.

Fig. 117. - Repurgator.

In some establishments there are even two repurgators used. The one already described, the other one between purifiers and gasometer, and this arrangement is especially useful where exceptionally bad carbonates are decomposed. The second one may also be arranged as a washing cylinder. In some establishments, where the carbonate used is pure and yields a fair quality of gas, a repurgator or wash cylinder is sometimes used between pump and condenser when gas only passes to purify it from impurities taken along from the pump and valves, instead of the coal repurgator. This is an exceptional carefulness on the part of the manufacturer, seldom experienced, but highly advisable, when a high class of beverage is desired. The re-purgator used as wash cylinder has the arrangement represented in this cut, and is described hereafter.

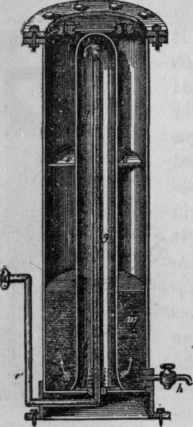

This repurgator or wash cylinder is made of the same material and constructed in the same shape and way as the repurgator Fig. 117. Near the bottom is a tin tube r inserted, which connects with the pump, and reaches in the upper space of the cylinder. Over this tube, in the inside of the cylinder, is put another cylinder about 4 inches wide, made of copper and tin coated. This inside cylinder, closed at the upper part, rests on some metal plate to give it support with its open end, and around this are punched 5 to 7 rows of small sieve holes. The inside cylinder with its semi-globular top reaches almost to the cover, and between both a rubber plate is inserted firmly which secures the cylinder. About 10 inches from the top of the inside cylinder is a perforated copper plate, ss, tinned, which may get its support by some project adjusted on the inside cylinder. This plate covers the space between the two cylinders, so that the gas must pass through the plate sieve and get minutely divided again. All the parts inside the repurga tor must be well tin-coated. The cylinder is filled with pure water, in which some soda solution may be added, to about one-third its height, through which the gas passes, getting washed again. Cock h is for discharging the water when renewing it. Openings on the cover are also for the pressure-gauge and the tube leading the gas over to the condenser.

Fig. 118. - Repurgator or Wash Cylinder.

If this repurgator is arranged as described and the cut represents, no water will be forced over to the liquid in condenser.

These two kinds of repurgators may also serve for another practical purpose at the same time: They can be used as cylinders for compressed carbonic acid. The latter may be collected up to 200 pounds, thus giving the necessary pressure when bottling prepared mineral waters direct from the condenser after the intermittent plan without the use of the pump.

The apparatus represented in next illustration is of similar construction and workmanship. The arrangement for washing the gas is peculiar.

The arrangement for purifying the gas is indicated by the letters L L L L. The purifiers are of glass, so-called "woulf-bottles". The carbonic acid exerts within the generator and purifiers but a slight pressure; it flows into the gasometer, where its weight gets balanced; only the pump and the condenser with the parts between them are influenced by gas-pressure. The first purifier is generally tin-lined copper, the second, third and fourth are of glass. The washing liquid is introduced by the funnel tubes l l l l, the contents discharged at the cocks m. Absorption of air by these tubes cannot take place, as the washing liquid in purifiers is highly charged with carbonic acid, displacing atmospheric air. The liquid never rises in those tubes to overflowing. Extra purifying cylinders are frequently stationed between or after these purifying bottles. Their object is to divide the glass bubbles into minute particles. This is accomplished by perforated attachments, as shown in the annexed illustrations.

Continue to: