Pneumatic Method

Description

This section is from the book "The Volatile Oils Vol1", by E. Gildemeister. Also available from Amazon: The Volatile Oils.

Pneumatic Method

In the course of time a number of so called improvements of the enfleurage process have been tried, however, with but little or no success. Best known of these is the "pneumatic method" of A. Piver.2) It consists in passing a current of air, or better still of indifferent carbon dioxide (CQ2) over the flowers and then through the absorption liquid (liquid fat or alcohol). The current of air carries with it the volatile sub-stances exhaled by the flowers and in turn gives them off to the liquid. The apparatus is so constructed that the gas passes through it, several times. The apparatus possesses the theoretical advantage that the fat does not come into contact with the flowers, thus avoiding loss of fat. Moreover, the use of fat can be circumvented since the extraits aux fleurs can be prepared directly. Practically, however, the process does not appear to have been used.

2. Extraction with non-volatile solvents with the aid of heat:

Infusion, maceration or enfleurage A chaud.

As a means of extraction purified animal and vegetable fats such as beef fat, lard, olive oil, sometimes also paraffin oil (comp. p. 260) are used in this process. Paraffin oil, as already mentioned under the enfleurage process, is less adapted since it has a lesser absorption capacity for perfumes than have the fats. However, even solid paraffin (m. p. 66°) is occasionally used. With its aid products are obtained which remain solid even in the tropics, hence do not require special containers for shipment.

The flowers to be extracted either, in bulk or tied into sacks made of fine linen, are immersed in the fat heated to about 50 to 70°. The time of extraction varies with the plant materials and lasts up to 48 hours. The fineness of the aroma of the pomade is inverse to the time of exposure of the flowers to the action of the fat. If prolonged unduly, other odoriferous substances that interfere with the quality of the perfume are also absorbed. The extraction being completed, the fat is expressed from the flowers with the aid either of hydraulic presses or of centrifuges (fig. 65, p. 267). The recovered, partly aromatized fat is treated with fresh flowers. This is repeated ten to fifteen times1) until the fat has acquired the desired strength as to odor. The floral extracts thus obtained are known by the same names as those obtained by the enfleurage process and are treated in like manner for the separation of the volatile oil. Here also the recovered fat, the corps epuise, is not used again in the perfume factory but finds its way into the soap industry.

1) According to Hesse, the extraction of 1000 g of jasmin flowers with petroleum ether yields only 178-g of volatile oil. Comp. Berl. Berichte 33 (1900), 1589.

2) Piver's absorption apparatus is illustrated in Wagner's Jahresbericht 1864, p. 499.

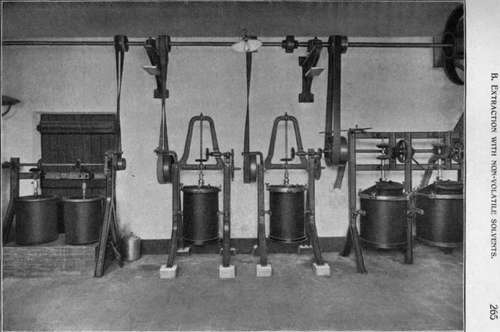

Fig. 64.

Apparatus for the extraction of pomades with alcohol (Batteuses a extrait). Parfumeries de Seillans, Dep. du Var, Southern France.

This process is applied to violets, roses, orange blossoms, lilies of the valley, etc, whereas jasmine, tuberose, and jonquil are not thus treated because of their small yield.

1) According to Labbe the average is 6 to 8 times. H. Labbe, Essais des Huiles essentielles. Paris, p. 11.

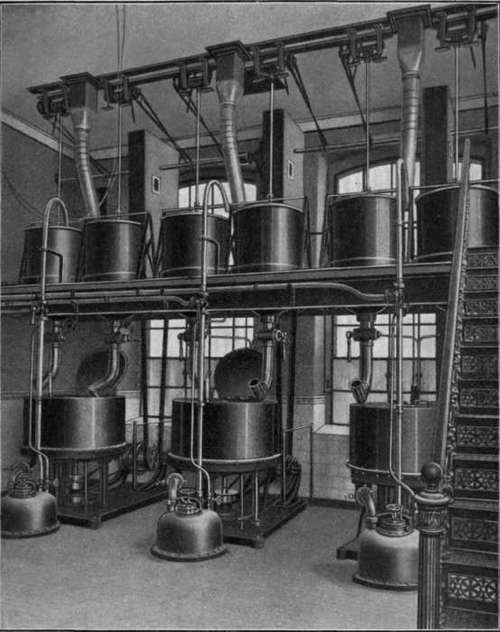

Fig. 65.

Apparatus for maceration and separation of the fat from the flowers by means of centrifuges. Schimmel &) Co.

Continue to: