Construction - Tables. Part 6

Description

This section is from the book "The Art And Craft Of Cabinet-Making", by David Denning. Also available from Amazon: The Art And Craft Of Cabinet-Making.

Construction - Tables. Part 6

Fig. 191. - Simple extending Dining - table Framing.

As is no doubt well known, dining - tables are made to expand and contract by means of a screw worked by a large key. It is unnecessary to say more about these screws than that they can be got from any dealer in cabinet brass-work, etc, and that they are fitted to the end rails of the framing. The simplest form of extending dining - table may be gathered from the plan of framing illustrated in Fig. 191. From this it will be seen that there are two pairs of side rails, one pair fitting within the other, so that when the table is closed only the ordinary framing is seen. Such a table naturally does not admit of very great extension, and is chiefly valuable here as all tray-frame tables are made on the same principle. If it is wanted to draw out more extensively, three sets of slides or frames must be made, and so on. Within reason there is no limit to the number of slides, and, as stated, any but the largest dining - tables may be made in this way.

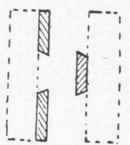

Now so far only the fact of the slides fitting against each other has been referred to, but any one can see there must be some connexion between them. The simplest form is to plough a groove, say 1 1/4 ins. wide by 3/8 in. deep along one pair of slides, and fix a corresponding piece on the others, as shown in section Fig. 192. In this case a flat rail, say 3 in. wide by 1 in. thick, fixed to the under edges of each frame, will be necessary to keep them close. The rail on the inner framing may be so arranged that it forms a stop and prevents the two ends of the table being drawn apart. Of course the inner framing itself must clear the rail on the outer one. The arrangement may easily be made by dovetailing the ends of the rail into the lower edges of the outer framing, making the inner frame so much narrower and fastening the cross rail on below its edges. The slides should be of good substance, say 1 1/2 ins. thick and from 4 ins. to 5 ins. wide. The best way of connecting the framing with the legs is by dovetailing, as indicated in Fig. 88 (p. 158); but those who prefer may dowel or mortise and tenon.

Fig. 192. - Construction of Slides.

The loose ends of the outer framing or slides should be sunk or housed to the depth of, say, 1/4 in. in the legs when the table is closed. This will be neater in appearance than if they just fitted against them, and besides, additional strength is given through the frame being supported at each end by the legs instead of only at one. The strain on the slip which fits into the groove is relieved.

Instead of having a plain slide and groove, it is better to make these in dovetail form, as in section Fig. 193. This shape tends to bind the sliding frames to each other, but it must be confessed it is by no means easy for any but the most skilful to make a perfect fit. The parts must work together without sticking or binding on the one hand, and without any looseness to admit of irregular play on the other. With a short length this is comparatively easy, but the longer the slide the greater the difficulty. The groove is cut as before, and then dovetailed with a specially shaped rabbet plane, viz., one with a sole which is at an angle with the sides instead of square. The dovetailed piece requires no special tools, being merely planed on the bevel and then screwed on to the slide. With such construction the transverse pieces across the bottoms of the frames may be omitted, though no harm can ever result from using them.

For those who cannot make the dovetailed groove, it may be said that another plan is sometimes adopted which practically gives the same result in an easier manner. It is simply to bevel off three pieces of equal thickness, say 1/2 in. stuff, as shown in section, Fig. 193.

By fastening two of them to one surface of the frame, and the centre one to the part which works against it, it will at once be seen that a sliding dovetail is formed.

This method may not meet with the approval of some cabinet-makers, but many good diningtables have been made in which it is adopted. The slips should be glued and screwed on, the screw-heads being well sunk. It may be well to note that the grooves and dovetails should not be quite straight, but be raised a trifle towards the centre from the ends, i.e., slightly curved upwards, so that when drawn out there is a slight tendency to lift the frame towards the middle. Not much rise is wanted, only sufficient to counteract what would otherwise be the natural drop.

This of course is greater in a long than in a short table, so that it is impossible to say exactly what slope should be given to the grooves, etc.; but as some idea, 1/8 in. may be named for a table drawing out to 8 ft. long. The easiest way to get a graduated rise and one equal in corresponding parts is to prepare a piece similar to a straight edge, and use it as a template.

Although there is no absolute necessity for them being so, custom decrees that the loose leaves of a dining - table should be 18 ins. to 20 ins. wide. Reference has already been made to the edges being dowelled, and it is only necessary to say here that the dowels and holes should be regularly placed so that the leaves are interchangeable, though as a matter of fact it is usual to mark the edge of each leaf, showing its natural position. To lessen the friction of the upper edges of the frame as they work under the fixed portions of the top, it is better to raise these slightly by pieces of veneer glued on to the top edges of those parts of the frame to which they are attached. The veneer gives sufficient clearance, and the slight rise is not observable. The top, it seems almost superfluous to say, must not be glued down, but be fastened with screws.

Fig. 193. - Dovetailed Slide.

To prevent any of the slides being withdrawn various devices are adopted, and there is little to choose between them if the stop is satisfactory. One good and neat method is by means of brass or iron plates, say \ in. thick and measuring about 1 1/2 ins. long by I in. wide. These are fixed on the lower edges of two touching parts of the frame with a portion projecting, so that on the slides being drawn out as far as intended they come in contact with each other. Those who prefer some other form of stop will have no difficulty in devising one.

Ordinary and miscellaneous tables have now been sufficiently referred to. There are many other kinds, such as pedestal writing-tables and dressing-tables, which will be found mentioned elsewhere; and in concluding this chapter it may be said that few if any leg-tables are made in which the principles of construction vary to any considerable extent from those which have been named.

Continue to: