Saws

Description

This section is from the book "The Art And Craft Of Cabinet-Making", by David Denning. Also available from Amazon: The Art And Craft Of Cabinet-Making.

Saws

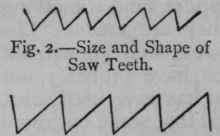

On looking through any tool catalogue the novice may be bewildered by the number he sees named. If he asks advice about the different sorts he may be told they are all useful if not absolutely necessary. No doubt they are so in certain circumstances. It all depends on the kind of work to be done. Without at all pretending to write a treatise on saws and their varieties, it will be well for the novice to understand something about the principles on which they are made. The serrated or toothed edge is, of course, well known, but the minuter differences which exist have probably not been regarded, though any one who has ever used saws, even occasionally, must have noticed that some cut more easily than others. It does not, however, follow that because a saw cuts well in one material it will be equally good in any. Thus there are saws which are specially adapted for cutting thick, soft wood with the grain or 'ripping,' while others have a different form of tooth, which makes them more useful for cutting hard, thin wood across the grain. The cabinet-maker has little use for the former kind, as most of his work is in comparatively hard wood, while there is so little ripping to do that he can very well dispense with a saw of the best kind for that purpose. All the same, he wants one with which he can manage any ripping which he may have to do, and if he is going in for several he may as well get a rip saw among them. For ordinary work, however, he can manage very well with a 'half-rip' or 'panel' saw, the teeth of which may not be so good as some others for cutting pine with the grain, but will do very well. As a good deal depends on the size as well as the shape of the teeth, let it be said that a handsaw, the general form of which is shown in Fig. I, with about six teeth or points to the inch, is what is wanted. The teeth should be pointed as in Fig. 2, and not as in Fig. 3, though these are best for ripping solely.

Fig. I - Handsaw.

A good handsaw should be flexible, so that when bent it will resume its flatness, and any bend observable would at once proclaim it to be defective. On looking at the teeth it will be seen that they are slightly bent alternately to each side. This bending is termed the setting, and is in order that the friction between the plain surface of the blade and the wood may be minimised, so that the passage of the saw is made as easy as possible. Too wide a set would, however, cause too wide a cut or 'kerf,' so that, especially when cutting thin stuff across the grain, the saw would wobble and cause an unnecessary amount of strain in keeping it straight and to the line.

It will also be noticed that the teeth, instead of being filed straight across the blade, at right angles to it, are slightly on the slant. This is to give each tooth as much as possible of a cutting edge, for if filed straight across the action would be entirely a tearing one, and the labour of sawing would be thereby greatly increased. Naturally in course of time the points get blunt, and the saw requires resharpening. This the novice may do for himself, but if he is wise, and there is a tool-shop or some one handy who is accustomed to this kind of work, he had better get it done for him. The sharpening and setting of saws is an art which is not picked up in a day. Sometimes, however, the user may be so placed that it is a case of Hobson's choice whether he does the work himself or puts up with a blunt saw, and the following hints may be useful to him. A triangular saw file will be required. Instead of occupying space with figures and diagrams showing at what angle to work the file, it will be better to direct the worker to notice how the teeth have been shaped, and to follow in the old lines as closely as possible.

Fig. 3. - Rip-saw Teeth.

First of all, a file should be run lengthwise from end to end of the saw to reduce all the teeth to the same level. They are then to be filed to get the points sharp. In doing this, care should be taken to have them equally filed, for of course if any of the cutting points project beyond the others, they will have to do most of the work, as those set back will to some extent be inoperative. The setting of the teeth sideways is usually done by hammering alternate teeth over the edge of a block of iron, then reversing the saw and treating the other side in the same way. Perhaps in expert hands this is the best method of setting, though opinions differ on the point. Without discussing the pros and cons, it may, however, be admitted that the novice at saw-sharpening will find the use of one or other of the saw-sets which have been devised of considerable assistance to him. A great deal depends on the setting, so that it must not be done in an irregular manner, or it will be useless to expect the saw to work properly. To save repetition, it may be said that all saws are sharpened in much the same manner, the chief difference between the different kinds being in the shape, size, and set of the teeth. It may also be well to note that there is no abrupt transition from one kind to another, the differences in some instances being so minute that saws of different names almost merge into each other.

This is the case with the other two named on the list, the tenon and the dovetail saw, for they are practically the same things, the principal difference between them being that the latter is smaller and finer than the other. Both of them are used for a variety of purposes other than those indicated by their names, and the maker of small things will hardly need anything larger.

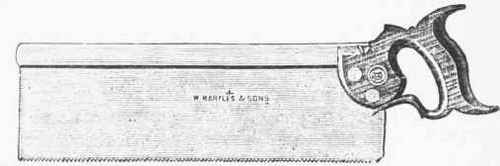

Fig. 4. - Tenon Saw.

The tenon saw is shown in Fig. 4, and the dovetail is similar in appearance, except that its handle is usually open at the bottom. Both these saws are made of thin metal, and are strengthened by a rim of iron or brass on the back edge; those with the latter being the more costly, but not necessarily better for work.

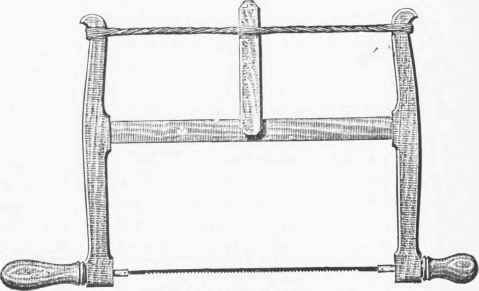

Fig. 5. - Bow Saw.

The bow saw - or, as it is often called, the turning saw - is shown by Fig. 5. Properly speaking, this is a composite tool, as the saw and frame are separable portions, though neither can be used without the other. The blade is between the two handles, and is kept at the requisite degree of tension by the cord and lever at the back. As the handles are movable, the saw can be turned with its cutting edge in any direction. The use of this tool is obviously to saw curves, which could not be done with a straight, wide saw of the ordinary kind. The blades can be obtained separately from the frame when needed, and are made in various lengths, to any of which the frame can be adapted by merely altering the bar between the string and the blade.

Continue to: