Boring Tools

Description

This section is from the book "Manual Instruction: Woodwork. The English Sloyd", by S. Barter. Also available from Amazon: Manual Instruction: Woodwork.

Boring Tools

Brace And Bits

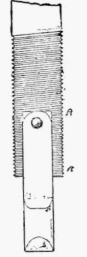

These are inseparable boring tools. The brace (fig. 77) is of the American pattern, with adjustable screw socket, having jaws to take any convenient sized rectangular shape.

The section of this socket in fig. 78 shows the threads of the socket, and it will be seen that the further the outer casing is screwed up the tighter will be the grip of the jaws on any object placed between them; in this case a portion of a bit is shown held firmly between the jaws. Enough of the thread of the inner screw has been removed in this drawing to enable the reader to see the rivet which holds the jaws together. This rivet is only fixed tightly into one jaw, and in the other the slot which takes it is rather larger, so as to allow the necessary 'play.'

Fig. 77.

Fig. 78. - Section and plan of socket.

The inner screwed socket is made with an 'interrupted thread.' A slot is cut out of each side wide enough to enable the jaws to open, though the threading on the outside runs as evenly as if the gap did not exist.

The shape of the inner socket, then, is circular at the top, but finishes at its lower ends in two threaded cheeks.

These are necessary to prevent the outer socket slipping round without turning the bit, and to give the requisite stability to the remainder of the thread.

Fig. 79 shows the shape of this slot, with another view of the jaws.

The brace is used by continuous turning to the right, and the twisting strain offered by the resistance of the wood or other substances bored is from right to left, and in the direction of the threads on the socket.

The action of boring, then, can only have the effect of tightening the jaws in their grasp on the bit.

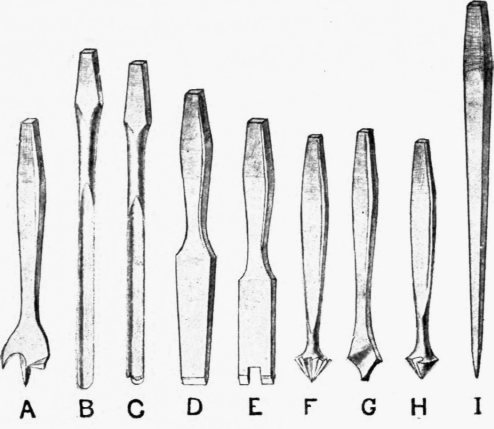

The bits for use in this brace, and of which a few common varieties are shown in fig. 80, are very distinctive tools, although something of the characteristics of the file, knife, and chisel are introduced into them.

The continuous spiral cutting action about the same axis, which is the peculiar feature of all boring, is absent in all of the cutting tools mentioned. The Centre Bit, A, is a kind in very common use for woodwork. The cutting end consists of a central pin, and at some distance on one side is an arm with a vertical cutting edge. This arm, in the twisting action of the brace, cuts the outline of a circular hole, which is deepened as the operator presses the top of the tool.

Fig. 79.-Side elevation of socket and jaws.

Fig. 80.

On the opposite side of the central pin is a flat cutter, which pares out the waste wood by a circular shearing action, but does not operate at quite the same depth as the vertical cutter.

The Pin Bit, B, is used to bore deep holes, and is very fast cutting. It is like a gouge in shape, and the long groove permits the 'core,' as the waste wood is called, to continually work upwards.

The Shell Bit, C, is like the centre bit in principle, only there is no central pin to assist in steadying and keeping it in its proper course. The sides of this gouge-like bit are of assistance, too, in the boring, as they are brought to a sharp edge by the maker, though, from the difficulty of sharpening them, they are certainly allowed to get dull in use.

The Screw-driver Bit, D, is similar to the screw-driver in use. When a large number of screws have to be put in, it is more con-venient to use the brace in preference to the more laborious and time-taking screw-driver. The screws can, moreover, be turned in better and more effectually with the brace.

Forked Screw-Driver Bit, E

Sometimes screws which have a rivet in the middle have to be put in, taken out, or tightened, as may perhaps be necessary to the riveted screws in saw handles, and this bit will then prove very useful.

Rose-Headed Countersink, F

This bit is for making shallow conical holes, and is the best kind for use in brass.

The Flat Countersink, G, and the Snail Horn, H, are for similar use in iron and wood respectively.

The Square Rimer, |, is used to enlarge already existing holes in brass or iron.

The Gimlet

The Gimlet (fig. 81) is another kind of bit which is much used. The point is spiral, similar to that of a screw, and the latter portion of the stem hollow, to admit the destroyed wood fibres. It is used for making holes for the easier insertion of screws.

The Twist Gimlet

The Twist Gimlet (fig. 82) is a better kind. It cuts faster and cleaner, and clears the waste wood better, besides making a slightly tapered hole. Ease in cutting saves the risk of the tang wearing the square hole in the handle and loosening itself.

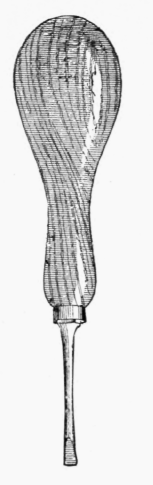

The Bradawl

The Bradawl (fig. 83) is a more primitive boring instrument, but none the less useful.

By pressing the bradawl into the wood, and so cutting and crushing without removing the adjacent fibres, a hole is made for a nail, rendering the labour of hammering easier, and decreasing the liability to breaking or bending the nail.

Fig. 81.

Fig. 82.

Fig. 83.

American bradawl pads are sometimes sold in which the blade is detachable, on the same principle as the brace and bit, but they are not necessary, and are expensive.

Fig. 84.

Continue to: