Gas. Part 6

Description

This section is from "The American Cyclopaedia", by George Ripley And Charles A. Dana. Also available from Amazon: The New American Cyclopędia. 16 volumes complete..

Gas. Part 6

The apparatus is a little more than half filled with water. A tube, c, passing through the axis of the cylinder, rises a little above the surface of the water, and delivers gas to the central compartment, from which it passes into each outer compartment successively through the openings g, g, g, g. The movement of the inner cylinder is in the direction of the hands of a clock, and it will be seen that the gas can only pass through the slit e when it is above the water. The gas constantly passes into that compartment which is on the left in the figure. As this fills it raises that side, and consequently the opening of the compartment above, out of the water, from which the gas flows till it is submerged and emptied at the opposite side. A large pipe conveys the measured gas to the reservoirs or gas-holders, the large cylindrical structures so conspicuous about gas works, and which are constructed much upon the principle of the gas-holder for experimental purposes shown in fig. 2. From the reservoir it is carried in cast-iron main pipes through the streets, and in small wrought-iron pipes into buildings, where it is measured to each consumer in small meters, which were formerly of a similar construction to the one above described; but of late years the wet has almost entirely been replaced by the dry meter, which was invented by Mr. James Bogardus of New York in 1832, and is one of the most ingenious of mechanical contrivances.

It was fraudulently patented in England by a person who had been employed by Mr. Bogardus, and afterward adopted in the United States without due credit to the inventor. His invention consists of a double bellows having four chambers, which, alternately moved by the pressure of the gas which is admitted upon one side or the other by the opening and closing of valves by such movements, communicates motion to a series of arms and levers by which a rotary motion is given to an index that registers the number of cubic feet passing through the different chambers of the bellows. As these have a measured capacity, the volume of gas passing through the machine is therefore shown. Instead of a double bellows with four chambers, a triple one with six was at one time constructed; but the machine was essentially the same, the arrangement of the arms and levers, the most ingenious parts, having almost the same form and acting upon the same principle as the double bellows with four chambers. - Wood Gas. It has been said that Le Bon, a Frenchman, made gas from wood about the end of the 18th century; but the invention did not prove practicable, as the gas had not sufficient illuminating power to compare with that made in England from coals.

The reason of its failure, as explained by Dumas, was that the heat employed was too low to produce the heavier hydrocarbons. In 1849 Prof. Petten-kofer of Munich made experiments showing that the gases evolved from wood at a heat sufficient to carbonize it consist almost entirely of carbonic acid, carbonic oxide, and marsh gas (olefiant gas being quite absent); but that the tarry matters and vapors at the same time produced are, by the. application of a much higher heat, capable of yielding a large quantity of heavy hydrocarbon gas. The manufacture of wood gas therefore requires retorts for converting the wood into empyreu-matic vapors, and others for converting these into permanent gases. The wood should be thoroughly dried before distillation. According to the experiments of Reissig, 50 kilogrammes of aspen wood yielded 592 cubic feet of purified gas and 10 kilogrammes of charcoal, and the same quantity of fir wood 648 cubic feet of gas and 9.5 kilogrammes of charcoal. Pettenkofer's analysis of crude gas is as follows:

Fig. 8.-Bunsen's Photometer.

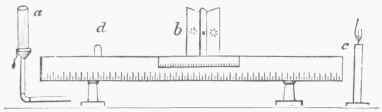

Fig. 9.-Gas Meter.

Heavy hydrocarbons............. | 6.91 |

Marsh gas............... | 11.06 |

Hydrogen................. | 15.07 |

Carbonic acid................... | 25.72 |

Carbonic oxide.................... | 40.59 |

The carbonic acid is removed by hydrate of lime. Reissig's analysis of the purified gas is as follows:

Heavy hydrocarbons............. | 7.24 |

Hydrogen.................... | 81.84 |

Marsh gas........................... | 35.30 |

Carbonic oxide.................................. | 25.62 |

The illuminating power of the hydrocarbons in wood gas is one half greater than that of an equal volume of olefiant gas. Its specific gravity is about 0.7, which is rather greater than that of average coal gas, for which reason it requires burners with larger orifices. Wood gas is successfully made in Germany.-Peat Gas. Peat yields in dry distillation, according to an analysis by Vohl of a sample from Zurich, the following proportions of gaseous, liquid, and solid matters:

Gases.................. | 17.625 |

Tarry matters..................... | 5.375 |

Aqueous distillate................. | 52.000 |

Peat coke......................... | 25.000 |

The same apparatus is used as for wood gas. Reissig used a fat peat obtained near Munich, 134 lbs. of which yielded 337 cubic feet of gas of good quality, having the following composition:

Heavy hydrocarbons................... | 9.52 |

Marsh gas...................... | 42.65 |

Hydrogen...................... | 27.50 |

Carbonic acid.............................. | 20.33 |

-Resin Gas. Resin yields a gas of high illuminating power, but its use is necessarily restricted by its limited supply. Several years ago it was successfully employed at the Philadelphia works to increase the richness of coal gas, and is now used in several southern towns. -Petroleum Gas. Petroleum is used in small works for making illuminating gas in this country, and very largely in Germany, Austria, and Russia. The crude oil is conducted from a reservoir continuously into red-hot cast-iron retorts, from which it passes through purifying apparatus, one vessel of which contains hydrochloric acid. One hundred weight of Pennsylvania oil yields about 1,600 feet of gas, which when purified consists, according to Bolley, of

Heavy hydrocarbons.............. | 33.4 |

Light hydrocarbons.,............. | 40.0 |

Hydrogen..................... | 26.0 |

It has a specific gravity of about 0.7, and is the richest that can be made. It is used in burners which consume only from one half to two cubic feet per hour, and it is estimated that 200 cubic feet are nearly equal in illuminating power to 1,000 feet of coal gas. The New York mutual gas light company own a patent for a process of making illuminating gas from the naphtha which passes over in the first part of the distillation of petroleum, and mingling it with coal gas, by which it is said that the latter is greatly enriched. The naphtha is volatilized in a separate boiler, and sent into retorts of similar construction to those for coal, where by the application of a cherry-red heat it is converted into a gas rich in heavy hydrocarbons, mostly of the character of. those made in using crude petroleum. The gas is conducted into a reservoir common to it and the coal gas, where the two mingle, in accordance with the law of the diffusion of gases. - Oil Gas. The fixed oils are excellent gas materials.

Continue to: