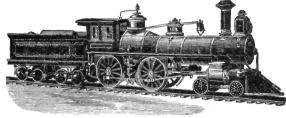

STEAM-ENGINE 1817

Description

This page of the book is from "The New Student's Reference Work: Volume 4" by Chandler B. Beach, Frank Morton McMurry and others.

STEAM-ENGINE

1817

STEAM-HAMMER

engines are rated in horse-power, one horsepower representing the work of 33,000 foot-pounds per minute. (See Dynamometer.) The performance of a steam-engine is indicated by the pounds of steam or water it consumes per horse-power per hour. For noncondensing engines 35 lbs. of steam at 100 lbs. pressure is a common performance. The best large condensing engines give records of from 17 to 20 lbs. of steam at 100 lbs. pressure for one horsepower for one hour. The following are terms used to designate different forms of engines. Horizontal, inclined and vertical refer to the position of the cylinder. High and low, as applied to speed, are relative terms. A speed of 150 revolutions per minute is a medium speed. Much above or below this is called high or low. Non-condensing and condensing are terms referring to the exhaust. In a noncondensing engine the exhaust is directly into the air; in a condensing engine the exhaust steam is condensed usually by contact with cool running water. Simple and compound are terms referring to the number of expansions used in the engine. In a simple engine there are a single cylinder and a single expansion; in the compound engine there are at least two cylinders and two expansions. Compound engines are more economical. Rotary engine is a form of engine in which the piston rotates. In the common steam-engine the piston moves backward and forward. A rotary engine has the very decided mechanical advantage of compactness and of direct application of power without crank and fly-wheel, but no rotary engine of the many that have been invented has ever shown itself economical or durable, except the steam-turbine. (See Turbine.)

A Locomotive is a steam-engine so arranged with wheels as to drive itself on an iron or steel track. As a steam-

engine the locomotive has a number of special features. It carries its furnace and boiler with it, and must also be supplied with an auxiliary car or tender for carrying water and fuel. The engine is double, that is, there is a high-pressure cylinder with piston on each side of the locomotive. Many modern locomotives are also compound steam-engines, that is, the steam-expansion takes place in two cylinders, a

high-pressure and a low-pressure cylinder. The steam-pressures commonly used are from 150 to 200 pounds per square inch. The oscillating, straight-line motion of the piston is converted into the rotary motion of the driving wheels by the usual mechanism of a cross-head and crank. The engine must be reversible. This is accomplished by a link-motion due to Stephenson, by which the connection of the valve-mechanism with the driving parts can be shifted through an angle. A requirement of the locomotive is the development of a large power in a limited space and with a limited weight. This means the burning of a large amount of fuel per square foot of grate-area, and requires forced draft. It is accomplished by exhausting steam directly into the smoke-stack. The American and European locomotives differ little as steam-engines, but present quite different external appearances. The large cab for the engineer, the pilot or cow-catcher, the headlight, the prominent whistle and bell are striking external features of the American locomotive. The frame of the engine and boiler is also quite different, that of the European locomotives being more rigid than can be used on American railroad-tracks. The first successful locomotive is due to George Stephenson (q. v.), and was used to haul coal for the Killingworth colliery in 1815. At the opening of the Stockton and Darlington railroad, an English line of 37 miles opened in 1825, a Stephenson engine, weighing eight tons and capable of 16 miles per hour, was used. Of the early locomotives R. Stephenson's Rocket was one of the most famous. At a competitive trial of locomotives in 1829 this engine showed a speed of from 25 to 30 miles per hour. These early locomotives are pygmies compared with the heavy, high-speed machines of to-day. Speeds of 100 miles per hour have been frequently exceeded in the last few years by express-locomotives. The largest locomotive in the world is one in use on the Illinois Central Railroad for hauling freight-trains over some steep grades on its line. It was built by the Brooke Locomotive Works, and weighs, without tender, over 230,000 pounds. The largest locomotive works in the world are the Baldwin Works at Philadelphia, Pa. A. P. Carman. Steam=Ham'mer, a hammer which is raised by the direct action of steam on a piston in a steam-cylinder. It is used in forging iron, particularly for large and heavy work. The first idea of the steam-hammer is due to James Watt, but the first practical scheme of a steam-hammer is due to James Nasmyth (q. v.). His first machine was made in 1843. The piston moved by steam raises the hammer-head or "tup," until the steam is cut off and allowed to