The Story In Photo-Engraving

Description

This section is from the book "The Wonder Book Of Knowledge", by Henry Chase. Also available from Amazon: Wonder Book of Knowledge.

The Story In Photo-Engraving

Modern advertising would not have been possible without photo-engraving. Attention has been attracted, desire has been created and goods have been sold, largely through the pictorial or other artistic embellishments which have lifted particular "ads" out of the mass and attracted the favorable attention of the cursory reader. Pictures are the universal language, not only to those of divers tongues, but to those of every stage of mental development.

Photo-engravings are a comparatively modern product. They superseded wood engravings, which "for years has been the recognized medium for illustrations to print on a type printing press. Photo-engravings, broadly speaking, are divided into two classes - line engravings and halftones. The distinction between them lying in the fact that one, as its name implies, is a reproduction of a drawing made in lines or * stipples, while the other, the halftone, gets its name from the method of its manufacture.

Briefly stated, the process of making halftones is as follows: The subject to be engraved is photographed through a halftone screen, so-called. This halftone screen is a glass plate ruled with lines at right angles ranging, for different purposes, from 60 to 200 lines to the inch. This screen is placed between the lens and the sensitized plate which is to be the negative. The necessity for this screen is due to the fact that a photograph is made up of "tones." That is to say, that the color changes imperceptibly in subtle gradations of light and shade. If this copy were photographed on a piece of copper it would present no chance for the etching fluid to act. The idea is to break up the surface into various sized dots, as the various gradations of color on the original cannot be transferred by any other method to a sheet of copper and etched.

The various tones must be changed either to lines or dots, so as to make a printing surface for the ink roller of the press to operate. This is necessary to get the desired printing surface.

The dots are of various sizes, ranging from a minute stipple to a solid black, and they present to the eye the same effect as the unbroken tones of a photograph. The negative when finished shows the drawing exactly like the original. The whites are opaque, the solid blacks are clear glass, the intermediate tones showing the same values in stipples of various sizes. The film of the negative is next removed from the glass, turned and placed on a heavier plate glass with a number of others and printed on a sheet of metal which has been coated with a sensitized solution.

Halftone Engraving.

* Illustrations by courtesy of Gatchel & Manning.

This plate of heavy glass containing the several negatives is placed with the sensitized metal in a printing frame. The light passes through the clear part of the negative, the solid parts prevent the passage of light; thus we have the light acting chemically on the sensitized surface.

After the print is removed from the printing frame, it is developed, the parts acted on by the light adhering to the metal. The opaque parts, through which no light has penetrated, leave the solution soft on the surface of the metal. This is removed by placing in water and wiping gently with absorbent cotton. The print is then dried and heated over a stove which bakes the sensitized solution to the metal.

It can readily be seen that this sheet of metal is now in such shape that the etching fluid will etch away the uncovered portions of the metal and allow the protected parts, which represent the color of the original, to remain in relief. This plate is etched - a flat proof, so called, is pulled on a hand press - and it is then taken up by the re-etcher. The re-etcher is the artist of the etching room. He takes the plate and by covering up certain parts and etching again gives additional play of color. Smaller developments of lights are worked out by careful manipulation of the etching fluid with small sable brushes. The differences in cost in the production of halftones is due largely to the length of time devoted to this work. The engraver or finisher then takes charge of it, preparing the engraving for the routing department, where the superfluous metal is removed. The plate is then returned to the engraving department, which completes the work, burnishing darks, engraving highlights, removing slight imperfections and otherwise perfecting the plate.

It is then proofed and blocked. Nine separate men handle each engraving in the halftone department.

The making of line engravings follows the same general course, with the exception that no halftone screen is needed, the copy to be reproduced being already made up of lines or dots or a combination of them. In the handling of line work, eight skilled men successively handle each plate.

In addition to plates made by either line or halftone process, combinations of the two are frequently used, as, for instance, where decorative pen work is used to embellish a halftone picture, or where lettering is to be used in connection with a halftone and form part of the same plate. These plates made up of both line work and halftones are known as combination plates or double-prints, depending upon the way they are produced. In both cases, negatives are made of both the halftone and line copies.

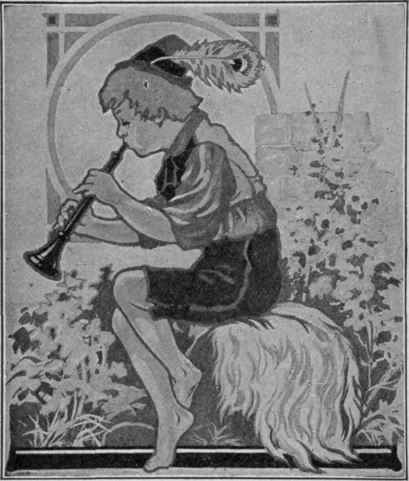

Line Engraving.

Combination Engraving.

Combination plates are made by combining the halftone and line negatives together and making one complete print on the metal.

Double-print is used where the surface is covered with halftone screen, either the line or halftone negative is printed on the metal, the other is superimposed on it.

The Benday process, so called, is the use of mechanical appliances for adding lines or stipples to either drawings or plates. Its use is very extensive in the making of tint blocks or color work, used either in connection with line or halftone key plates.

The highlight process, possible only with certain kinds of copy, is a modification of the halftone in which, by manipulation of the time of exposure and the screen when making the negative, the halftone stipples are lost and in this way halftones are produced in which there are pure whites, without the necessity of the finisher cutting them by hand.

Continue to: