Description Of The Furnace

Description

This section is from the book "Leaching Gold and Silver Ores. The Plattner And Kiss Processes: A Practical Treatise", by Charles Howard Aaron. Also available from Amazon: Leaching Gold And Silver Ores.

Description Of The Furnace

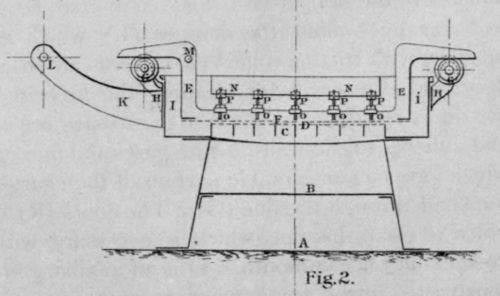

A is the shaft into which the pulverized ore is showered by the feeding machine, placed on the top of the cast iron frame B. The shaft is heated by two fireplaces (C). The ashpits of these are closed by iron doors, having an opening (E), provided with a slide, so that more or less air can be admitted below the grate, and, consequently, more or less heat generated. In order to obtain a perfect combustion of the gases, leaving the firebox through the slit (T), an airslit (U), connected with the airchannel (F), is arranged above the arch of the firebox. This slit also supplies the air necessary for the oxidation of the sulphur and the base metals. Another advantage of this construction is that the arches above the firebox and firebridge are cooled and prevented from burning out. The roasted ore ac-mulates in the hopper (K), and is discharged into an iron car by pulling the damper (L), which rests on brackets with friction rollers (M). N is an observation door, and also serves for cleaning the firebridges. O are doors to admit tools in case the roasted ore is sticky and adheres to the walls. The gases and fine ore dust, which forms a considerable portion of the charge, leave the shaft through the flue (G). The doors (R) are provided to clean this flue, which is necessary, with some ores, about once a month. D is an auxiliary fireplace, constructed in the same manner as the fireplaces on the shaft, which is provided to roast the ore dust, escaping through the flue (G), in passing through the chamber (H). P are doors for observation and cleaning. The larger portion of the roasted dust settles in the chamber (V). provided with discharge hoppers (I), from which the charge is drawn into iron cars by moving the dampers (S). The rest of the dust is collected in a system of dust chambers (Q), connected with a chimney which should rise from 40 to 50 feet above the top of the shaft. At the end of the dust chambers is a damper by which the draft of the furnace can be regulated. The dry kiln can also be used as a dust chamber, and the waste heat of the furnace utilized for drying the ore before crushing it. The firing of the furnace is done on one side, and all discharges are located on the opposite side."

The Stetefeldt Furnace.

Continue to: