Ink

Description

This section is from the book "The Manufacture Of Boots And Shoes: Being A Modern Treatise Of All The Processes Of Making And Manufacturing Footgear", by F. Y. Golding. Also available from Amazon: The Manufacture Of Boots And Shoes.

Ink

The edges of vamps, goloshes, quarters, etc., if not turned in, should be coloured the same as the face of the leather. If black, the ink should be jet black,* and of such a composition that it readily adheres to the leather. If for coloured goods, the ink or stain should be of the same tint as the material.

The ink should be confined to the edges, and not be smeared over the face of the leather. A fine, short-haired tooth-brush, protected by a metal plate either side, which reaches to within one-sixteenth of an inch to the edge of the hair, will be useful for this purpose.

The Other Preparatory Processes, such as the perforating of the toe-caps or vamps by means of perforating pliers or machine, marking imitation facings by means of a facing-marker, compass, or blunt non-cutting awl, demand careful attention prior to the fitting together of the parts.

The Turning-in of the edges of the vamps, quarters, or other parts would be done either by hand or machine. When executed by the hand-process a dull, blunt, short knife is often used. The work should be turned in evenly throughout its entire course. The turning-in may be to a dull-marked line, or by taking a regular amount from the cut edge. The turned-in portions of topbands and facings should show a level bead of leather of uniform width. Machines are used for turning-in, some of them requiring work of a given shape, while others are adaptable for varying shapes. The best of its kind is the "Lufkin " folder. This machine cuts or nicks the edges, folds or turns them over, and compresses and flattens them. The edges may be to any shape, flat or curved. Work to be folded by this machine should have left on when cutting an even amount for turning-in, which is best done by having the patterns so made, and not by allowing on to a "raw-edge" pattern an amount which varies at the discretion of the cutter. Uniform skiving is also essential, and the width of skive should be twice that of the folded-in portion.

* A good black ink may bo made from a decoction of logwood chips, to which is added sulphate of iron and bichromate of potash. A little gum added will prevent spreading.

Aniline dyes are useful for this purpose.

To remove ink stains from fabric oxalic acid should not be used. Two parts of tartar with one part of powdered alum is more suitable.

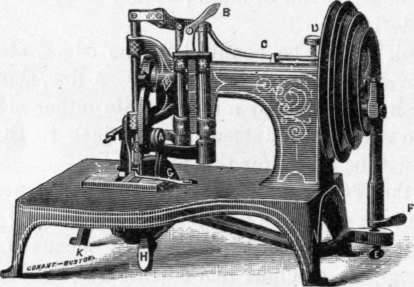

Fig. 188.

The "Lufkin" folder, or turning-in machine, is illustrated by Fig. 188. The following will give the principal parts : A is the nut that may he operate! by the thumb. By lowering it, the knife may he made to give the cuts or nicks closer together or finer. This will be necessary in turning in smaller curves. If the nut is moved up, the feed, or distance, between the serration is greater. The feed on general work is set to give about 10 to 14 cuts to the inch.

B is the lifter used to raise and lower the feed-bars. It should be raised when placing the work to be folded.

C is the feed-bar presser-spring. The pressure on the feed should be as light as possible, just sufficient to feed the leather.

The screw D will increase or decrease the pressure, the former only being desirable when the feed slips.

E is the ball-screw thumb-piece used to regulate the stroke of the folding-lever. It should be so adjusted that when the folded material is under the folding-lever, and the link on the driving-wheel is at its highest, the spring should slightly move. If it does not move, the nut F should be loosened, and the screw E turned in a little. If the folding-lever has too much pressure, the screw E is turned out of the balance-wheel connecting-link.

The gauge G is adjustable, and is used to regulate the width of the turned or folded edge. The edge of the leather to be folded is directed towards the guide-gauge ; when inside curves are reached, such as the curve of a vamp, the material should be pressed harder against the gauge. When starting certain work, the work should be kept away a little from the gauge at first to prevent too wide a fold.

The right-hand lever, H, when raised up towards the operator, removes some of the pressure on the folding-lever, enabling a seam to pass without mutilation. The other lever, K, when pressed down, prevents the nicking of the work passing under the knife. It is used when the seam is under the knife.

The machine is run about 400 revolutions per minute, and the balance or driving-wheel has three grooved wheels, 5, 4, and 3 in. diameter respectively. The transmitter has corresponding grooved wheels, enabling the speed to be adjusted at will. The skived edges are coated with cement* and allowed to dry, being in condition when "tacky."

The knife requires careful attention. It should be sharpened on its bevel edge only, and the cutting edge kept perfectly square with the sides. It is adjustable, so as to go below the under-knife or cutter-block a sixteenth of an inch, and set so that the cuts are as near the folded edge as possible without being visible on the face. This especially so when on inside curves.

* Made from virgin rubber dissolved in naphtha, benzine, or bisulphide of carbon. It should be fine, and not too stringy.

Fig. 189.

The under-knife or cutter-block should be sharpened on its front face where the knife passes. It must be kept straight so that it may fit the knife, and must be adjusted close to the knife so that it may cut clean.

Button-Piece Beaders, etc. - The Urquhart button-scollop header is illustrated by Fig. 189. It moulds and affixes the insertion beading to the shape of the scollop, and is a very useful machine to expedite button-work. Machines are also used for back-strap beading, and fancy-stitching perforators or flower markers, for indicating the design of flowering, if ornamental stitching be needed.

Continue to: