Problem 48. The Patterns For A Square Pipe Describing A Twist Or Compound Curve

Description

This section is from the book "The New Metal Worker Pattern Book", by George Watson Kittredge. Also available from Amazon: The new metal worker pattern book.

Problem 48. The Patterns For A Square Pipe Describing A Twist Or Compound Curve

As problems of this nature frequently occur in connection with hot air pipes, grain chutes, etc., this problem is given as embodying principles which can often be made use of. The upper opening of the pipe in this case is required to be in a horizontal plane, while the lower opening is in a vertical position and placed at a given distance below and to one side of the top, the pipe describing a quarter turn when viewed from either the top or the front.

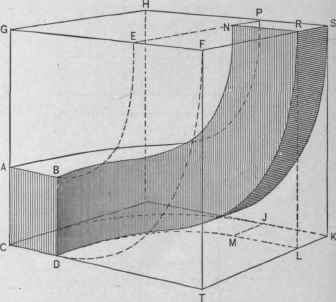

To more fully illustrate the nature of the prob- lem, a perspective view of it is shown in Fig. 328, in which the pipe is represented as being contained within a cubical shaped solid. The solid, of which the pipe is represented as forming a part, is shown in outline, the pipe itself being shaded to show its form, while upon the front and lower side of the solid are shown in dotted lines the front elevation and plan of the pipe. Thus G F T C represents the front view of a solid just large enough to contain the pipe, in which ABCD shows the position of the lower opening, and ABE FD C shows the curve of the pipe as seen from the front. G H S F is the top of the solid in which the upper opening N P S R is situated. The curve of the pipe in plan has been projected to the lower face of the solid by vertical lines, R L, and others not shown, and is shown by C J K L M D. To state the case simply, then, ABE is the profile of the piece of metal forming the top of the pipe, while D M L and C J K are the two miter lines, or the plans of the intersecting surfaces, and CDF is the profile of the lower side of the pipe intersecting the same miter lines. The top and bottom pieces being developed, it is only necessary to reverse the operation and consider the lines of the plan D M L and C J K as the profiles of the front and back pieces respectively, while ABE and CDF become the miter lines or elevations of the intersecting surfaces.

A part of these operations arc carried out in detail in Fig. 339, where the elevation and the plan are drawn directly in line with each other; the various points being represented by the same letters in the two illustrations. For the pattern of the top piece divide its profile A B E by any convenient number of points (1, 2, 3, etc.), from which drop lines vertically cutting the two miter lines D' M and C J of the plan, as shown (the figures of the plan 2 to 11 have no reference to this part of the operation). Upon R 8, drawn at right angles to the direction of the mold, lay off the stretchout of ABE, through which draw the usual measuring lines. With the T-square placed parallel to R 8 and brought against the several points in the two miter lines cut lines of corresponding number; lines traced through the points of intersection, as shown by R T and U S, will give the pattern of the top piece. It will be noticed that owing to the contrary relation of the two curves it is necessary to have the points of the profile occur more frequently near B than E, as otherwise they would intersect the miter line D' M too far apart near D'. while they would occur more frequently than is necessary near M. As there is no curve from A to B of the profile, that part of the pattern from R to S will be a duplicate of the plan view, consequently the curve from R to the measuring line drawn from S may be traced from the plan. The development of the pattern for the lower side of the pipe is not given, but it would be accomplished in exactly the same manner as that of the top piece, using C D F as the profile instead of A B E.

Fig. 328. - Perspective View of a Pipe Describing a Twist or Compound Curve.

For the pattern of the front piece of the pipe, divide its profile LMD' by any convenient number of points 1, 2, 3, 4, etc., from which drop lines vertically, cutting the two miter lines D F and B E, as shown. Upon Q 1, drawn at right angles to the direction of the mold, place the stretchout of L M D', through which draw the usual measuring lines. With the T-square placed parallel to Q 1 and brought against the various points' in B E and D F cut corresponding measuring lines. Lines traced through the points of intersection, as shown by Q P and O N, will give the required pattern.

Fig. 329. - Patterns for a Pipe Describing a Compound Curve.

The pattern of the back piece not given in the illustration can be developed in exactly the same manner as that of the front by using C J K as the profile and proceeding otherwise the same as in the foregoing.

PROBLEM 49. The Construction of a Volute for a Capital.

It is sometimes desirable in designing capitals of large size to construct the volutes of the same of strips of metal cut and soldered together. The principal characteristic entering into the design of the volute, and that which distinguishes it from an ordinary scroll, consists in a pulling out or raising up of each successive revolution of the scroll beyond the former, thus producing a ram's horn effect. This feature of its design is also frequently embodied in the construction of scrolls used to finish the sides of large brackets or head blocks, such as may be seen by reference to Fig. 87 on page 12. As all volutes, except those of the Ionic order, always occur under the corners of the abacus and project diagonally from the bell of the capital, their forms can only be correctly delineated in a diagonal elevation.

In Fig. 330 is shown a diagonal elevation of a portion of the bell and abacus of a capital with the volute. Immediately below the same, DACB shows one-quarter of the plan of the capital, turned to correspond with the elevation, in which the various curves of the volute have been carefully projected from the elevation, as shown by the dotted lines. As the pattern cutter is dependent upon the drawing of the plan for his miter lines, considerable care must be given to this part of the work. On account of the small scale necessary in drawing Fig. 330, an enlarged view of the plan of the helix of the volute, as seen from below, is shown in Fig. 331, in which the various curves can be followed throughout their course.

The volute as here given consists of two side pieces or scrolls, an outside cover or face strip, an inside cover and two narrow strips to fill the space where the second curve of the scroll projects beyond the first. The outside cover or face strip extends from F of the elevation to G, where it is met by the inside face strip, which begins at H. To obtain the pattern for the inside cover, divide the profile from H to G into any convenient number of equal spaces, and lay off a stretchout of the same upon the center line of the volute in plan, A B, extended toward K, as shown by the nine spaces on the upper side of the line. Drop lines vertically from each of these points intersecting the upper line of the side of the scroll in plan. Place the T-square parallel to the stretchout line B K, and bringing it successively against the points in the plan, drop lines cutting corresponding lines of the stretchout. Then a line traced through the points of intersection, as shown from I to J, will give the shape of the side of the strip to cover the space between the points H and G of the elevation. A similar course is to be pursued in obtaining the outside cover or strip extending from F to G. This stretchout consists of fourteen spaces, and is shown on the lower side of the center line A K, the pattern being shown from L to M. The pattern for the remaining strip consists of a stretchout of seven pieces taken from the profile between G and the termination of the scroll line. Points from this part of the profile are intersected with two miter lines in the plan, one forming the outer line of the strip, or its finish against the more projecting part of the scroll, and the other forming its finish against the lower scroll or inner edge of its first or outer curve. In Fig. 331 the lines showing the projection of the inner part of the volute beyond the outer curve are clearly seen. In the lower half the lines corresponding to the points 1 to 7 of the profile are shown by corresponding numbers. Lines dropped from the points on both these lines to corresponding lines of the stretchout will give the pattern as shown from M to N.

By inspection of the drawing it will be seen that the outline of the volute, as given in the elevation, does not represent exactly the "true face" of the scroll. As the variations in the angle of the side of the central part or helix of the scroll are only such as can be produced by the springing of the metal necessary to bring it into shape, no allowance need be made for such variation in cutting the pattern directly from the elevation. Careful measurements of the stem or lower part of the volute, as shown in the plan, however, show that the distances from point 9 to points a and b, if laid off on a line parallel to A B, would reach to points a2 and b2. These points projected back into the elevation locate them in that view at a2 and V. Therefore the outline of the back of the stem will have to be extended as shown by the dotted line from F to a3. This outline can be accurately obtained, if deemed necessary, by the raking process described in connection with a number of other problems in this section of this chapter, and need not be repeated here. The correct outline, from G to b3 is omitted to avoid confusion with the figures.

Fig. 330. - The Construction of a Volute for a Capital.

To avoid confusion of lines in dropping the points from the different parts of the profile to the miter lines and thence to the stretchout, only the first and last of each series or stretchout have been shown by dotted lines in the drawing.

Continue to: