Problem 90. The Patterns For A Diagonal Bracket Under Cornice Of A Hipped Roof

Description

This section is from the book "The New Metal Worker Pattern Book", by George Watson Kittredge. Also available from Amazon: The new metal worker pattern book.

Problem 90. The Patterns For A Diagonal Bracket Under Cornice Of A Hipped Roof

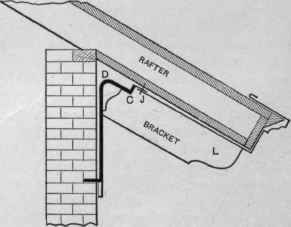

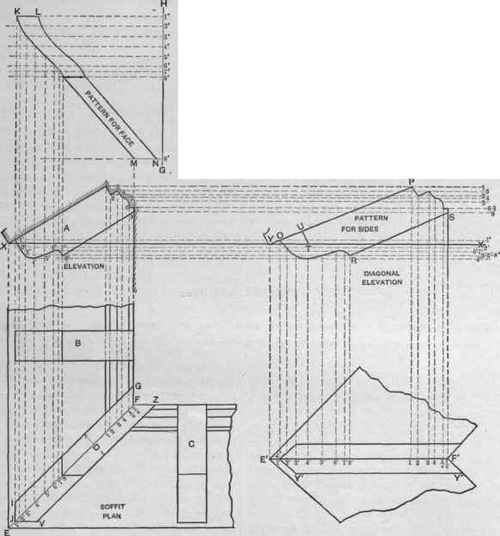

In Fig. 386 is shown a constructive section of the cornice of a hipped roof, under which the bracket L fits against the planceer and over the bed molding C. Fig. 387 shows an inverted plan of the angle of such a cornice, including two normal brackets B and C, and the diagonal bracket D, of which the patterns are required. At A, in line with one arm of the cornice in plan, is also shown a duplicate of the profile of the normal bracket. E F represents the miter line of the planceer over winch the diagonal bracket is required to fit.

Two distinct operations are necessary in obtaining the patterns of the bracket D, one for the face pieces and the other for the sides. As the bracket is placed exactly over (or more properly speaking under) the miter in the cornice, one-half its width must be drawn on either side of the miter line, as shown in Fig. 387. Each half of its face thus becomes a continuation of the moldings forming the faces of the course of normal brackets of which it is a part. Therefore the normal profile X 8 of the bracket A is the profile to be used, and I G and J F form the miter lines for one half the face.

The usual method in obtaining the pattern for the face piece would be to divide the profile of A into any convenient number of spaces and lay off a stretchout of the same upon any line drawn at right angles to the direction of the mold - that is, at right angles to I J or G F - after which lines should be dropped from the profile upon the miter lines and thence into the stretchout. However, as the miter is a square miter, the short method is available; hence the stretchout line is drawn at right angles to the horizontal line of the elevation X X, as shown at H G. The usual measuring lines are drawn and intersected with lines from points of corresponding number on the profile. Lines traced through the points of intersection, as shown by K M and L N, will give the pattern for half the face.

The operation of obtaining or "raking" the pattern of the side is exactly similar to that employed in Problem 88, with the difference that while in Problem 88 the side is elongated vertically, in the present instance (the cornice remaining horizontal, and the bracket being placed obliquely) it is elongated laterally or horizontally. The operation is also complicated by the addition of a profile at the back edge of the bracket where it is required to fit over the bed molding of the cornice. To obtain the pattern of the side it is first necessary to ascertain the correct horizontal distances between the various points of the profile. The points already made use of in obtaining the face may be used for this purpose. Therefore, drop lines from each of these points vertically, intersecting the side of the bracket, or, what is the same thing, the center line E F, as shown in the plan, Fig. 387, by 1', 2', 3', etc. The profile at the back of the bracket in the elevation must also be divided into a convenient number of spaces, as shown by the small figures, which must also be dropped upon E F, as shown, and numbered correspondingly.

Fig. 386. - Sectional View of the Cornice of a flipped Roof, Showing Bracket.

Fig. 387. - Inverted Plan of Cornice and Method of Obtaining Patterns.

From each of the points in the profile of the elevation carry lines indefinitely to the right, as shown. At any convenient point at the right of the plan, draw another plan of the diagonal bracket, so placed that its sides shall be parallel with the horizontal line X X of the elevation, all as shown, and upon its center line E' F' transfer the points and spaces from E F. Low from each point in the line E' F', erect lines vertically, in-tersecting lines of corresponding number previously drawn to the right from the elevation. Thus, lines drawn upward from the intersections 1, 2, 3, 4, etc., on the line E' F' intersect with horizontal lines 1, 2, 3, 4, etc., while lines drawn upward from the intersections 1', 2', 3', 4', etc., on the line E'F'intersect with horizontal lines 1', 2', 3', 4', etc. Lines traced through the points of intersection, as shown by O R S P, will bo the required pattern of the side.

If it be desirable to ascertain the exact angle to which to bend the edges or flanges of the bracket to fit against the planceer it may be accomplished in the following manner: Extend O P of the pattern of the side till it intersects the line from X of the side elevation, as shown at Y. Upon the solid line X X in diagonal elevation establish any point, as T. Through the point T and at right angles to Y P draw a line intersecting the line Y P at U.

As the angle of the plan shown in Fig. 387 is a right angle, construct a right angle, ABC, Fig. 388, and bisect it, obtaining the miter line B L. Now take the distance from Y to T in diagonal elevation, and place it on the miter line B L in Fig. 388, from B to D. At right angles to B L draw a line through the point D, intersecting the sides of the right angle A B

Fig. 388. - Diagram for Obtaining Angles for Bending the Flanges.

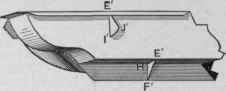

C at E and F. Now take the distance T U in diagonal elevation and set it off from D toward B, locating the point H. Connect the points E, H and F; then will the profile E H F in Fig. 388 represent a section across the hip at right angle to its rake and will also be the angle to be used in putting the straight parts of the face together, as shown by E' H' F' in Fig. 389. The angle which the sides of the bracket make with the planceer will be the complement of the angle H B D of Fig. 388 and may be obtained as follows: Parallel to B L, in Fig. 388, and through the point E, draw I K, representing the vertical side of the bracket; then will the angle J E I represent the profile required for bending the flanges on the side of the bracket, the profile being shown in position by I' E' J' in Fig. 389.

Fig. 389. - Perspective View of Finished Bracket.

In Fig. 389 is shown a perspective view of the finished bracket as seen from below.

Continue to: