Hot And Cold Water Supply. Part 5

Description

This section is from the book "Standard Practical Plumbing", by R. M. Starbuck. Also available from Amazon: Standard practical plumbing.

Hot And Cold Water Supply. Part 5

Self-closing work closes very quickly also, and is open to the same objection as Fuller work. When the pressure of the supply is very heavy, this trouble is a serious one. The only way to proceed against the trouble is to use air chambers. Air, unlike water, is very compressible, and easily takes up the shock occasioned by the closing of valves.

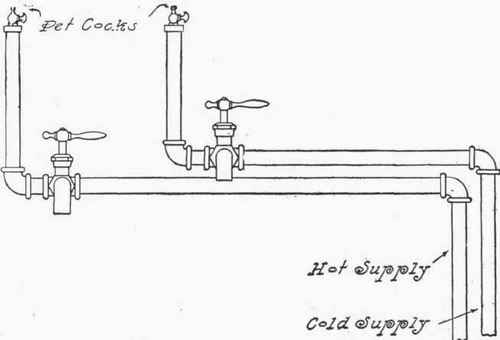

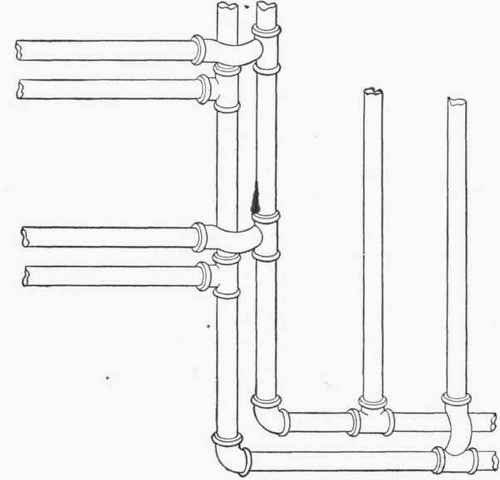

Fig. 260. - Air Chambers.

In Fig. 260 is shown the customary method of providing air chambers at the different fixtures. This method consists in turning upward with the supply pipe a distance of a foot or so. Whenever either of the faucets shown in Fig. 260 is closed, or faucets or valves in other parts of the house are closed, the resulting shock is taken up in these air chambers, hammering and vibrations being thus prevented.

Sometimes air chambers are formed by continuing the supply pipe past the faucet horizontally, without turning the pipe up. The last-named method is a very poor one, however, for the water soon carries out the air with it and the air chamber becomes waterlogged and absolutely useless. The air chambers shown in Fig. 260 will in time also become water-logged, and when once in this condition cannot be renewed with air by drawing off the water in the piping, as the water in the air chambers will not pass out of them, owing to the fact that there is no air pressure at their upper ends to force the water out. The method shown in Fig. 260 is a very common one for providing air chambers on the supply system, but is in reality a poor method, as the water will gradually absorb the air and carry it off through the faucet in minute particles, and in time, as stated above, absolutely destroy the air chamber. The method shown in Fig. 261 would present a means of renewing the air in these air chambers, and thus overcoming the difficulty above mentioned, but is a device seldom made use of, for some unknown reason. The illustration referred to shows a pet cock used at the upper end of each air chamber. When the pipes begin to hammer, it shows that the air chambers have become water-logged, in which event it is necessary simply to close the main stop- and wastecock, allowing the pipes to be drained. When the pressure has been shut off, open the pet cocks until the water has run out of them, when they may be again closed. In this way, by the use of pet cocks, it is an easy matter to renew the air chambers at each fixture in the house. The method is sometimes adopted of using a single large air chamber on the main supply pipe, allowing this device to perform its work for the entire house. In Fig. 262 is shown a desirable method of constructing and connecting such an air chamber. A short branch may be taken from the main supply, into the bottom of the pipe forming the air chamber, and between the chamber and the main, a stop- and wastecock should be placed.

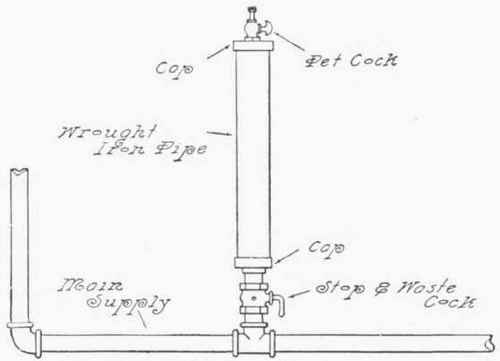

Fig. 261. - Use of Pet Cocks on Air Chambers.

Fig. 262. - Air Chamber on Main Supply Pipe.

The chamber may be made of 2-, 3- or 4-inch galvanized wrought-iron pipe, capped at the upper end, and tapped to receive a pet cock. The joints should be made absolutely air tight. When this air chamber becomes water-logged, it is a simple matter to close the stop- and wastecock and open the pet cock, thus allowing the water standing in it to drain out through the waste. After the chamber has been entirely drained, close the pet cock and open the stop- and wastecock, and it is again ready to perform its duties. If the stop- and wastecock is not used on the branch to the air chamber, it will be necessary in draining it to close the stop- and wastecock on the main supply, thus shutting off the entire building.

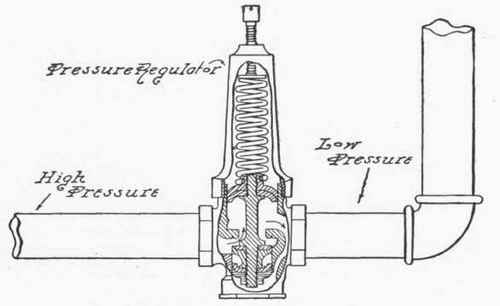

On many supply systems, the use of a water-pressure regulator is accompanied by good results. It makes the valves and pipes safe from the dangers due to high pressure, prevents hammering and vibrations of pipes, and avoids the splashing of water when drawn under high pressure. When used on pressure work a relief valve attached, allows for the expansion, and in the case of a break in the main, the regulator remains closed, thus preventing the siphonage of the boiler. The action of the pressure regulator is automatic, and when once set needs no further attention. The regulator shown in Fig. 263, works by means of a spring which is compressed, the spring being put under any desired tension by screwing down on the set-screw at the top.

Fig. 263. - Use of Pressure Regulator.

A few remarks are necessary concerning the running of water pipes.

They should always be so run that no sags or dipping of the pipe may occur and thus form a trap which cannot be drained. When piping in which sags exist, must be drained in cold weather in the event that the house is to be vacant, it is impossible to drain the traps thus formed, and their contents often freeze and burst the pipe, whereas the owner has assured himself of protection against this trouble by having the system properly drained.

Pipes should never be run against cold cellar walls, or other walls that may at any time be exposed to frost. When it is necessary to so run them, however, they may be protected by covering them with hair felt or other similar material, or by boxing them. Several concentric boxes with 1-inch air spaces between them provide excellent protection to pipes against extreme cold. It is often a good plan to run the main supply pipe through the cellar underground as far as possible, this course not only preventing freezing, but keeping the water cooler than when run overhead.

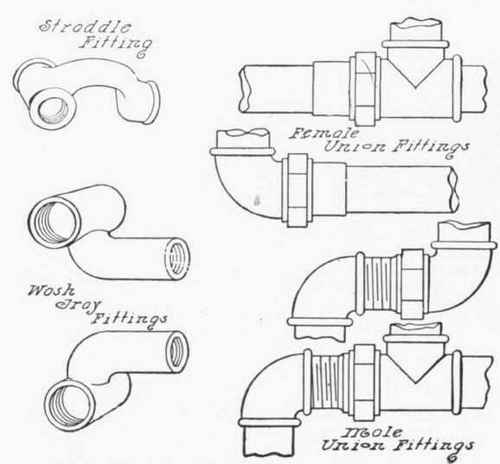

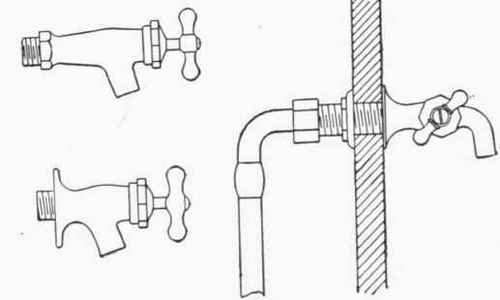

Fig. 264. - Special Supply Fittings.

The "sweating' of exposed water piping is a matter which causes much trouble. It is caused by the formation of condensation on the surface of the pipes, the moisture forming in sufficient quantity to flow along the pipes and drip off. The reason for this trouble is that in warm places the moisture of the air condenses against the sides of the cold pipe. It may be overcome by covering such pipes. It sometimes occurs between floors, the moisture dripping down onto the ceiling below. In this case, a sheet metal gutter run under the pipe and pitched toward one end, and dripping into a drip pipe effectually remedies the difficulty. Such a drip may be carried into an open cellar fixture. There are several special supply fittings which are of excellent service, a few of which are shown in Fig. 264.

Fig. 265. - Use of Straddle Fittings.

The straddle fitting is a most valuable fitting for use on parallel lines of hot- and cold-water pipe. In many places throughout the house the hot- and cold-water pipes will be found running, side by side, and in the use of ordinary fittings it is usually a very awkward undertaking to cross over one of these pipes, with a branch from the other. The straddle fitting, as its form shows, is designed for this special purpose. The curved part of the fitting is of sufficient radius to entirely clear the pipe which it must cross.

The use of the straddle fitting is shown in Fig. 265, from which it will be seen that a fitting of this style not only adds greatly to the appearance of the work, but saves labor and the use of a number of fittings.

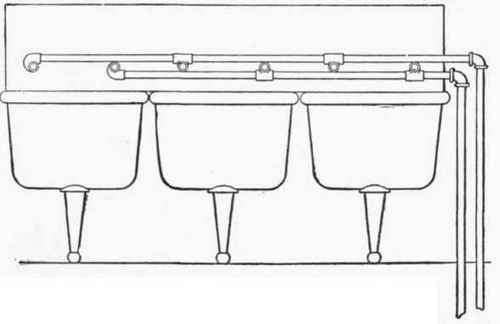

Fig. 266. - Wash-tray Bibbs.

Regarding the running of the hot- and cold-water pipes side by side, when so run horizontally the hot water should ordinarily be run above the cold water, as the heat radiated from the hot water will affect the cold water to a greater degree if the latter is run above. The male and female union elbows and tees shown in Fig. 264 represent another valuable type of fitting. It will be clear that fittings of this type are of great value where the work is close, and there is not sufficient room in which to use a tee or elbow and a union.

Fig. 267. - Use of Wash-tray Fittings.

In Fig. 266 are shown several different styles of wash-tray bibbs. In the use of the ordinary faucets on wash trays, with the handle upright, there is often difficulty, owing to the projection of the bibb handles so high up as to prevent the use of covers on the trays.

The wash-tray fittings to be seen in Fig. 267 are fittings which allow neat work to be installed in connection with wash trays. By means of them, the wash-tray bibbs may be kept on a straight line, as shown in Fig. 267. In the use of ordinary tees and elbows, the bibbs are on two horizontal lines, the hot-water bibbs being on a line above the cold-water bibbs. The wash-tray elbows and tees are each made in two styles, one to be used on the upper line, throwing the bibb opening down, and the other to be used on the lower line, to throw the bibb opening up.

Continue to: