Condensation. Part 3

Description

This section is from the book "The Engineer's And Mechanic's Encyclopaedia", by Luke Hebert. Also available from Amazon: Engineer's And Mechanic's Encyclopaedia.

Condensation. Part 3

On the top of the hot well is placed a snift valve, to maintain the water in the hot well at a certain height, so as to prevent the air from entering the boiler along with the water. The whole of the steam from the cylinder is condensed, the water returned to the boiler; but there is always a loss of water to a greater or less extent by leakage of the boilers, and the escape of steam at the joints, and at the safety valve; the water in the boilers would, therefore, in time, be reduced below the proper level, unless means were taken to replace the quantity of water so lost. To meet this difficulty, a small vessel, called a "still," is inserted in the top of the boiler, and connected by a pipe and cock with the upper chamber of the condenser. This still is charged with sea water, and when it is perceived that the water has become lower in the boiler, the cock is opened; and a communication being thus established with the condenser, a partial vacuum is formed in the still. This causes the water to boil rapidly at a much lower temperature than it would otherwise; and the steam rushing into the condenser, is condensed along with the steam from the cylinder.

The additional water thus obtained is delivered to the boiler by the action of the air-pump.

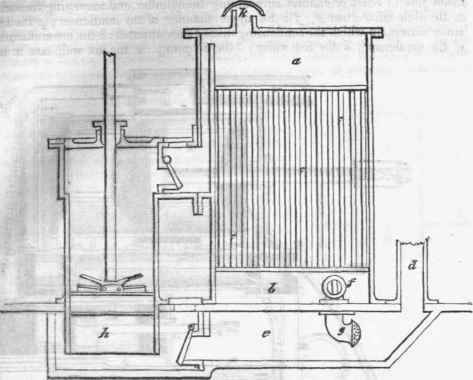

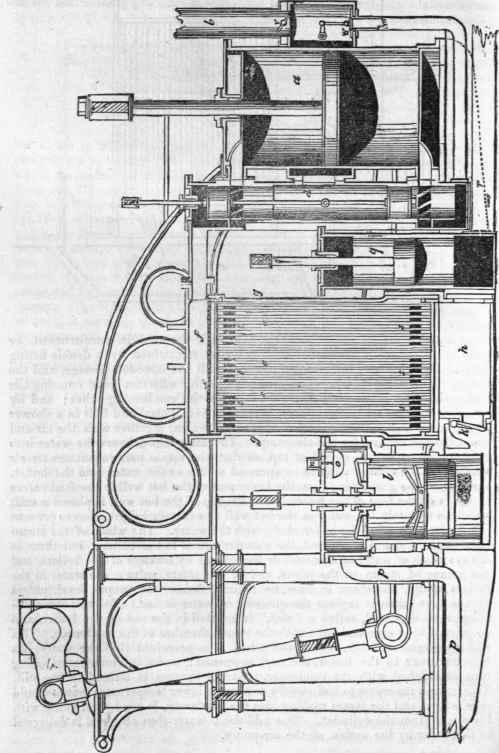

The annexed engraving represents, with some slight alterations, the arrangement adopted in a pair of engines constructed by Messrs. Hall, of Dartford, for the Wilberforce steam packet. We select it as the most perfect which we have seen, and because all the parts are distinctly shown. At a is the steam cylinder; b the steam pipe; c a belt or channel surrounding the cylinder, and conveying the steam to the slide valve chest d; fis the upper chamber of the condenser; g the cold water cistern, in which the condensing tubes e e are situated; h the lower chamber of the condenser; k the foot valve; l the air pump; m the hot well, cast in one with the air-pump; n the snift valve, attached to the float o; p the feed pipe, leading to the boiler; qis the cold water pump, placed between the slide case and the condenser; r the cold water supply pipe; the water is conveyed from the pump to the condenser by a channel cast on the foundation plate of the engine and enters the condenser by the apertures ss; tt are outlet passages by which it is discharged into the sea; v is the throttle valve, and w the blow-through valve; x in the upper chamber of the condenser, is the distributing plate; and y the pipe leading to the distilling vessel.

The axis of the side levers is not carried through the condenser, as is usual; but each lever plays upon a stout pin, firmly keyed into a massive block, or pedestal, cast on the foundation plate.

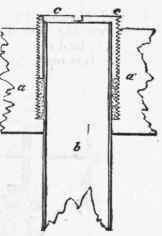

The figure in the margin shows the mode of fastening the condensing tubes; a is a portion of the upper plateof the condenser, madeof brass or cast iron, and having holes formed in it to receive the ends of the tubes, a portion of one of which b is shown of the full size. These holes are to the depth of about half an inch, made of a rather greater diameter than the tubes, and are tapped to receive a screwed ring or ferule c; the end of the tube being inserted in the hole, a ring of soft tape is slipped over the end of the tube and screwed firmly down into the hole in the plate, so as to press it into close contact with the surface of the tube; by which means a joint is formed perfectly steam and water-tight; and which yet allows for the expansion and contraction of the metal.

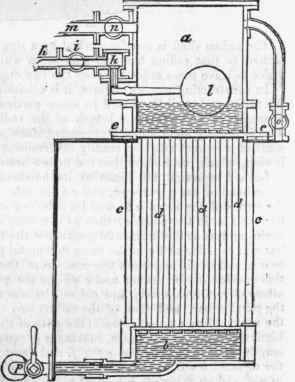

The annexed figure represents the distilling apparatus. At a is a cast-iron vessel bolted down over an aperture in the top of the boiler, and having a vessel b connected to it by rods c c. A series of brass or copper tubes d d connects the interior of the two vessels. The lower chamber, the tubes d d, and a portion of the upper chamber, contain sea water, which enters by the pipe h, connected with the cold water chamber of the condenser; k is a valve governed by a float l, by which the water is maintained at the proper level. From the upper part of the vessel a, a pipe m, furnished with a stopcock n, proceeds to the upper chamber of the condenser. When the attendant perceives the water in the boiler beginning to fall, he opens the cock n, and the steam from the water in the still rushes into the upper chamber, and is condensed along with the steam from the engines; and the water resulting is forced into the boilers by the air-pump. When the water in the boiler is by this means restored to its proper level, the cock n is shut, and the operation ceases.

When, from the water becoming saturated, it is required to "blow, out" the still, the cock n, and a cock i, on the pipe h, are shut; and steam is admitted from the boiler into the upper vessel, by opening the cock o and the cock p, which connects the lower part of the still with a discharge-pipe passing through the ship's side, and the water and sediment are driven out; after which, by reversing the position of all the cocks, the still is recharged with water from the cold water chamber of the condenser.

Mr. Hall's invention has been extensively adopted by the Admiralty, the East India Company, and various other companies; as well as private individuals. The Sirius of 320 horse-power, fitted with Mr. Hall's condenser, was the first steam vessel which crossed the Atlantic from this country.

Continue to: