Typical Welds And Repairs

Description

This section is from the book "Welding Theory, Practice, Apparatus And Tests Electric, Thermit And Hot-Flame Processes", by Richard N. Hart. Also available from Amazon: Welding: Theory, Practice, Apparatus And Tests, Electric, Thermit And Hot-Flame Processes.

Typical Welds And Repairs

The following instances of boiler repair are given by L. L. Bernier, in his "Autogenous Welding of Metals":

"Repairing Cracks Steamer 'Eugene Pereire' of the French Line:

"The boiler furnaces of the mail steamer Eugene Pereire of the French Line had numerous horizontal cracks above the grate bars. There were about 100 of these, and in two of the furnaces they extended from end to end of the corrugations.

"It had been attempted to stop the worst of these by plugging; but it would have been necessary to renew several furnaces, which would have detained the steamer for two months and caused great expense. All the cracks were wedged open with chisels and welded; all repaired parts were annealed with burners. In two spots where there were several adjoining cracks, a part of the furnace was cut out and replaced by a welded piece. No leak was observed at any of the 100 places so repaired at the hydrostatic or steam tests.

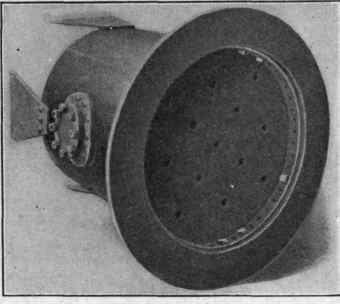

Fig. 49. - Repairing with the oxy-acetylene torch (Davis-Bournonville Company)

Fig. 50.

Fig. 51.

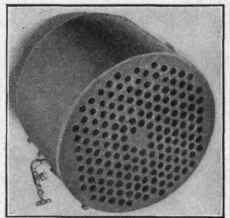

Fig. 50. - High-pressure tank for U. S. Navy. Ends and seams welded and 3/4" flange welded to end. Material 1/2 inch thick, size 36 x 30 3/4 inches. Tested to 250 lbs.

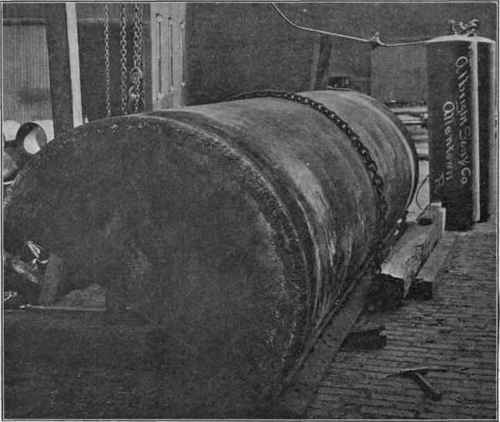

Fig. 51. - Steel tubes welded to shell.

"Only the sweating of a few drops, caused by trifling laminations, were discovered, and a little calking restored the water-tightness at such spots. The work lasted three weeks and cost $300. From the month of March of that year the steamer has been on the Algiers voyage, which is very trying for boilers on account of its shortness, the fires being banked and boiler temperatures changed so frequently. No trouble has been experienced with any of the welded parts."

Fig. 52. - Galvanized tank witn oxy-acetylene welded end piece (heat expansion would shear rivets).

"Repairing Corroded Parts on the 'Cholon':

"Oxy-acetylene welding may be used to add metal directly to the surfaces of plates, to repair corroded spots, such as are frequently found in various parts of boilers. The flame of the blowpipe is directed upon the plate, and when the latter begins to melt the workman presents to the flame a bar of soft steel about 7 by 7, which melts and fixes itself in drops on the corroded surface.

"The repairs of the Marsa, already referred to, give a sample of the value of the welding process, but the work performed on the Cholon, of the Compagnie des Chargeurs Reunis, from August 20 to September 20, 1906, presents a still more striking case.

Fig. 53. - Welded cylinder. Oxy-acetylene process.

"The eighteen corrugated furnaces of this steamer were badly eaten away on the surface. There was corrosion on each side and for some distance above the grate bars.

"The work was difficult to perform, as the workmen were compelled to be inside of the boilers; and were inconvenienced by the heat of the blowpipe flame; and the places to be welded were lower than the workmen's footing; 10,000 cubic feet of dissolved acetylene and as much of oxygen were used; about 200 pounds of steel were used to cover the corrosions and restore the plates to their original thickness. This work, at a total cost of $2,400, avoided the replacing of eighteen furnaces, as originally ordered by the government inspectors."

Continue to: