Chapter I. On Tools Generally

Description

This section is from the book "Practical Mechanics For Boys", by James Slough Zerbe. Also available from Amazon: Practical Mechanics for Boys.

Chapter I. On Tools Generally

Judging from the favorable comments of educators, on the general arrangement of the subject matter in the work on "Carpentry for Boys," I am disposed to follow that plan in this book in so far as it pertains to tools.

In this field, as in "Carpentry," I do not find any guide which is adapted to teach the boy the fundamentals of mechanics. Writers usually overlook the fact, that as the boy knows nothing whatever about the subject, he could not be expected to know anything about tools.

To describe them gives a start in the education, but it is far short of what is necessary for one in his condition. If he is told that the chisel or bit for a lathe has a diamond point, or is round-nosed, and must be ground at a certain angle, he naturally wants to know, as all boys do, why it should be at that angle.

So in the setting of the tools with relation to the work, the holding and manipulation of the file, of the drill for accurate boring, together with numerous little things, are all taken for granted, and the boy blunders along with the ultimate object in sight, without having the pathway cleared so he may readily reach the goal.

Varied Requirements

The machinist's trade is one which requires the most varied tools of all occupations, and they are by all odds the most expensive to be found in the entire list of vocations.

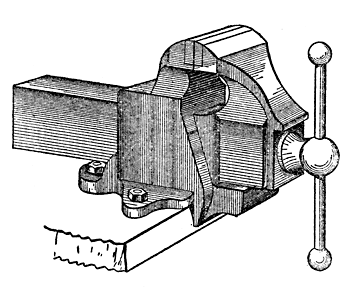

Fig. 1. Bench Vise.

Fig. 1. Bench Vise.

This arises from the fact that he must work with the most stubborn of all materials. He finds resistance at every step in bringing forth a product.

List Of Tools

With a view of familiarizing the boy with this great variety the following list is compiled, from which we shall select the ones essential in the initial equipment of a small shop.

Vises

One small, good vise is infinitely preferable to two bad ones. For ordinary work a 3-inch jaw is preferable, and it should be firmly mounted on the bench. So many kinds are now made that it would be a costly thing to purchase one for each special use, therefore the boy will find it profitable to make some attachments for the ordinary vise.

Fig. 2. Pipe Grip for Vise.

Fig. 2. Pipe Grip for Vise.

Swivel Vises

A swivel vise is always a good tool, the cost being not excessive over the ordinary kind. Then a pair of grips for holding pipe, or round material which is to be threaded, can readily be made.

The drawing (Fig. 2) shows a serviceable pair of grips, made to fit the jaws of a vise, and will be acceptable in much of the work. Then, the vise should be provided with copper caps for the jaws to be used when making up articles which would otherwise be injured by the jaws.

Fig. 3. Swivel Vise.

Fig. 3. Swivel Vise.

Let us get a comprehensive view of the different kinds of tools necessary in a fully equipped shop.

Parts Of Lathe

The first thing of importance is the lathe, and of these there is quite a variety, and among the accompaniments are the slide rest, mandrel, back gear, division plate, angle plate, cone plate and various chucks

There must also be change wheels, studs and quadrant plates, self-acting feed for surfacing and cross slide, and clamping nuts.

Drilling machines, both hand and power, hand and ratchet braces and breast-drill stocks.

Fig. 4.—Speed Lathe.

Fig. 4.—Speed Lathe.

Chisels

Chisels of various kinds, for chipping and cross-cutting; round-nosed, centering, set punches, tommies and drifts.

Back, tee and centering square; bevels, spirit level, inside and outside calipers, straight edges, rules and surface plates

Gages for boring, scribing blocks, steel and brass scribes, stocks and dies, screw-plates, taps for bolts, reamers.

Fig. 5. Calipers

Fig. 5. Calipers

Files for various descriptions, countersinks, frame and hack saws.

Grinding Apparatus

Emery wheel, cloth and paper, paper, flour emery, polishing powders, laps and buffs, and polishing sticks

Fig. 6. Engine Lathe.

Fig. 6. Engine Lathe.

Forge, anvils, tongs, swages, punches, bolt tools, hot and cold chisels, blow-pipe, soldering iron, hard and soft solders, borax, spirits of salts, oil, resin and spelter.

To this may be added an endless variety of small bench tools, micrometers, protractors, arbors, collets, box tools and scrapers.

Fig. 7. Center Gage.

Fig. 7. Center Gage.

Large Machines

The list would not be complete without the planer, shaper and milling machine, with their variety of chucks, clamps and other attachments, too numerous to mention.

The foregoing show what a wonderful variety of articles are found in a well-equipped shop, all of which can be conveniently used; but to the boy who has only a small amount of money, a workable set is indicated as follows:

A small lathe, with an 8-inch swing, can be obtained at a low cost, provided with a countershaft complete.

Chucks

With this should go a small chuck, and a face-plate for large work, unless a large chuck can also be acquired. This, with a dozen tools of various sizes, and also small bits for drilling purposes.

The lathe will answer all purposes for drilling, but small drilling machines are now furnished at very low figures, and such a machine will take off a great deal of duty from the lathe.

Fig. 8. Pocket Screw and Wire Gage.

Fig. 8. Pocket Screw and Wire Gage.

As the lathe is of prime importance, never use it for drilling, if you have a driller, as it always has enough work to do for tuning up work.

Continue to: