20. Chisels

Description

This section is from the book "Elements Of Construction", by Charles A. King. Also available from Amazon: Elements of construction.

20. Chisels

Chisels. (A.) Carpenters' chisels are used for paring and mortising. The paring chisel should be light, smoothly finished, and ground with a sharper bevel than that used for mortising, for which the heaviest chisel is none too strong.

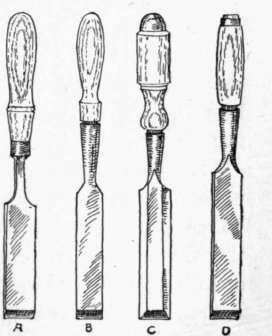

(B.) Chisels are "tanged" or "socket," according to the method by which the blade and handle are joined. The tanged firmer chisel (Fig. 38, A) is the older form, and is not so strong as the more recently designed socket chisel (B). For light work, the tanged chisel is preferred by many, but more commonly the socket chisel is used, as it is stiffer, not so easily broken, and has no shoulder to catch upon the edge of the wood when the tool is used. The beveled-edge chisel (C) is a favorite tool with pattern makers; and the mortise, or framing chisel (D), is designed for heavy use. A set of chisels consists of one each of the following dimensions: 1/8", 1/4", 3/8", i", 5/8", 3/4" 7/8S", 1", 1 1/4", 1 1/2" 1 3/4", 2".

(C.) A large, heavy chisel, 3 1/2" or 4" in width, called a " slice" or " slick," is used, like a paring chisel, upon heavy work.

(D.) Handles for paring chisels may be of any hard wood and of any convenient shape, as these should not be pounded upon. Although they are occasionally used for cutting small mortises, it is not a good practice, unless the tops of the handles are protected by leather or fiber tops. Mortising chisels should have handles of the toughest wood obtainable, preferably hickory, with leather nailed with small brads upon the top to protect the wood. If a leather washer is fastened to the handle by a pin or dowel, the wood will in time pound down and the leather be broken out and destroyed, while if bradded upon the handle, the leather may be renewed as often as necessary. An iron ring, or ferrule, is used by many to prevent the handle from splitting, but this will bruise the face of the mallet. A hammer should never be used upon any sort of wooden handle, as the handle will very quickly be destroyed, but a mallet will injure it comparatively little. In fitting the handle to the chisel blade, care should be used that they are in perfect alignment, as otherwise a sharp blow may break the blade.

(E.) In sharpening a mortise chisel, it should be ground at an angle of not less than 30°, as a thinner edge is liable to break upon coming in contact with a knot. A paring chisel may be ground as thin as 20°, as it does not have to stand heavy blows, and a better edge for the purpose may thus be obtained. In whetting a. chisel, the bevel must be carefully maintained, and the back kept perfectly straight, like the face of a plane iron, as otherwise it will be impossible to work to a line.

Fig. 38. - Chisels. A, tanged firmer chisel; B, socket chisel; C, beveled-edge chisel; D, mortise, or framing chisel.

Continue to: