Chapter XI. Flour And Bread

Description

This section is from the book "Experimental Cookery From The Chemical And Physical Standpoint", by Belle Lowe. Also available from Amazon: Experimental cookery.

Chapter XI. Flour And Bread

The composition of wheat may vary with several factors, such as varying rainfall, temperature, and other climatic conditions, irrigation, texture and composition of the soil, and the use of fertilizers. Bailey reviews all these factors and others in "The Chemistry of Wheat Flour."

The kind of flour and to a great degree its composition depend upon (1) the milling process, (2) the classes of wheat from which the flour is milled, and (3) the purpose for which the flour is intended. Flour is also made from rye, buckwheat, barley, corn, rice, potatoes, bananas, lima beans, cottonseed, and soybeans, but the term flour refers to wheat flour when no grain or product is mentioned.

The milling process and the structure of wheat. The wheat kernel may be divided into three main parts: the bran, the germ, and the endosperm, the relative proportion of each part of the entire kernel being respectively about 14.5, 1.5, and 84 per cent. Milling is the process of separation of the endosperm from the bran and germ. When no separation is made, or all the flour streams are reunited, the flour is known as whole-wheat flour, but otherwise the completeness of separation determines the resulting grade of flour. If the separation is so complete that only the heart of the endosperm is used, the resulting flour may be called a "fancy" or "short" patent. In general, only about 72 to 75 per cent of the endosperm is obtained in white flour, the remainder constituting bran and shorts. Between the two extremes of flour, whole-wheat and fancy patent, are many other varieties.

The steps in the milling process may include the following: cleaning, tempering, breaking, sifting, or separating the primary products, purifying, reducing, bolting, flour blending, and bleaching.

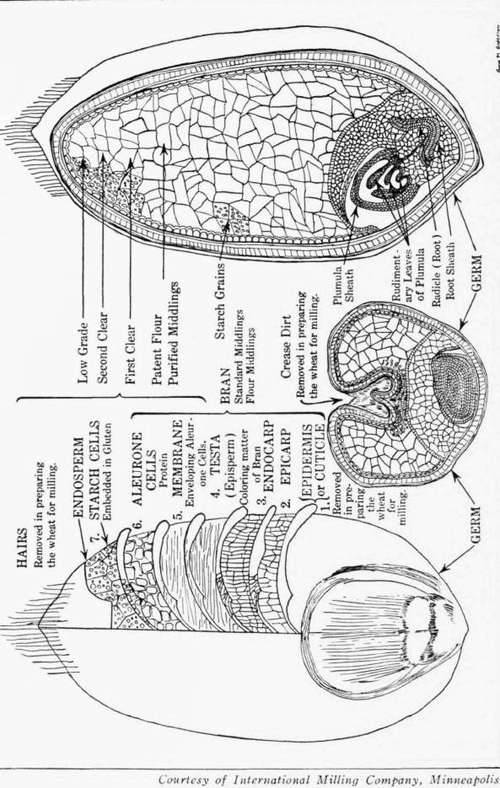

The structure of the wheat berry is shown in Fig. 42. Layer No. 1, sometimes called the bee's wings by millers, the hairs, and the dirt on the berry, particularly that in the crease, are removed in the cleaning operations preparatory to milling. Layers No. 2 to No. 6, shown in the surface drawing, and the longitudinal and cross sections constitute the bran coats.

The gross appearance of a cross section of a wheat berry varies somewhat with the type of wheat and the ripening conditions. Hard wheats are more flinty and vitreous than soft wheats. The proportion of gluten is usually higher in hard than in soft wheats, and the gluten forms a continuous matrix in which the starch granules are imbedded. When the grain contains a large proportion of gluten, the starch granules, as it dries out in ripening, are more firmly cemented to or held in the gluten matrix. In milling the vitreous wheats naturally tend to yield coarser particles and less free starch granules than soft wheats, unless the hard wheats are deliberately ground fine. If the weather is hot and dry after flowering of the wheat, a larger proportion of gluten and less starch are laid down in the kernel. It is known that vitreous barley has smaller starch granules than soft barley, and it is probable that this also applies to wheat.

Fig. 42. - The structure of a wheat kernel. The bran layers are shown peeled back from the kernel. The portion from which the different flours are obtained is shown in the longitudinal section.

In contrast to hard wheats, the soft wheats have air spaces throughout the endosperm. The endosperm is quite friable and naturally breaks into smaller particles in milling.

Tempering consists of adding a definite amount of water at a certain temperature to wheat berries, the proportion of water added depending on the moisture content of the wheat and other factors such as relative plumpness and hardness of the kernels. In tempering wheat the water is usually not left in contact with the wheat long enough for moisture to be absorbed by the endosperm. Thus the pliableness and toughness of the bran coats are increased so that they are more easily separated from the endosperm. Sometimes, to prevent the endosperm from breaking into very fine particles, the water is added in two portions, part of the first addition being absorbed by the endosperm.

The germ because of its high fat content is easily flattened or flaked and is removed by bolting from the other constituents of the wheat berry during milling. The endosperm constitutes about 80 per cent of the wheat berry. The starch is more concentrated in the immediate vicinity of the germ and in the interior of the endosperm. The concentration becomes less and less towards the outer layers of the wheat berry. The starchy endosperm being drier and more friable tends to shatter more readily when the berries are fractured or broken between rollers.

In the first breaks, the wheat kernels are mostly broken into large fragments by the corrugated rollers. The coarser fragments, which are separated from the finer ones by sifting, are returned to the next set of break rolls of which there are 5 or 6. Other things being equal, a larger proportion of fine particles is obtained from soft wheat than from hard wheat during the first breaks.

Bolting or sifting, which occurs after each break, is the separation of the coarse particles, which are reground, fine granules of flour, which are not reground, and intermediate particles, which are sent to the purifier.

Purifying refers to a part of the milling process whereby particles pass over a sloping, vibrating sieve. At the entrance the meshes of the sieve are fine but gradually increase in size to the discharge end. As the particles travel down this sieve they are separated according to size. During this process controlled air currents lift out the flakier and more fibrous particles. The remainder of the particles, known as purified middlings because they are freer from branny, fibrous material, yield a more highly refined flour after reduction.

The purified middlings are ground between smooth iron rollers to reduce them to the desired fineness. Since the flour bolted from the first grinding of any stream of purified middlings is more highly refined, because it is freer of fiber than that produced by subsequent grinding of the coarser residues, it is often used in making the so-called "short" patent flours.

Continue to: