Joining An Iron And Earthenware Drain

Description

This section is from the book "American Plumbing Practice", by The Engineering Record. Also available from Amazon: Plumbing: A working manual of American plumbing practice.

Joining An Iron And Earthenware Drain

Department of Public Works, 1 City Engineer's Office, Duluth, Minn., November 25, 1892. )

To the Editor of The Engineering RECORD.

Sir: Will you please discuss in your department of "Notes and Queries," the different methods of joining a 6-inch tile house drain to a 4-inch iron soil pipe, such as the introduction of the end of the soil pipe a foot or so into the tile and cementing well outside, use of a tile reducer 6 inches to 4 inches, use of an iron reducer 6 inches to 4 inches, use of a 4-inch iron "double hub," fitting into the body of the 6-inch tile pipe, and any other methods which you may know of, giving the advantages and disadvantages of each, with your judgment as to the best method X.

[In answering our correspondent's inquiry we shall assume, to prevent any misunderstanding, that by "soil pipe" he means the main drain of cast-iron pipe inside the house walls, receiving, through various branches the drainage from all the plumbing fixtures and, as a rule, running horizontally for a greater or less distance through the cellar before passing out at the front wall. This main pipe is in New York known technically as the "house drain," to distinguish it from the vertical lines called "soil" and "waste pipes," and also from the continuation of the main drain outside the house and extending to the public sewer, which is known as the " house sewer." The "house drain," whether above or below the cellar floor should always be constructed of iron pipe carried through and several feet beyond the house, vault, or area wall. From this point hard, salt glazed earthenware pipe may be safely used under proper conditions as to foundation, etc. If, however, the practice in Duluth corresponds more nearly to that of Chicago than New York, and the " house drain," as defined above, is commonly laid with earthenware pipe, so that the connections in question are made inside the house, we should answer that such arrangement is no longer considered good practice in this country, the safe rule being to use only iron pipe within the walls of a building.

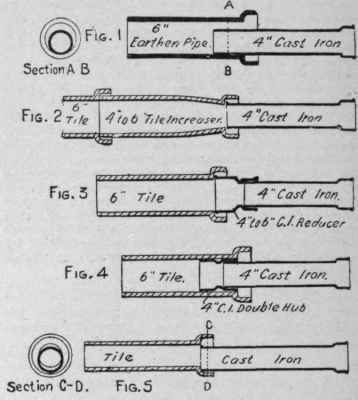

Presuming, therefore, that it is the connection of a cast-iron "house drain " with the earthenware drain outside the walls, the accompanying sketches will explain the methods suggested by our correspondent. In Fig. 1 the end of the 4-inch extra-heavy cast-iron pipe is introduced into the earthen pipe for any desired distance and the space above the iron pipe and the entire hub carefully filled with good cement mortar. This gives an easily made and strong connection, with a good and fairly continuous line of flow, and applicable to all cases where the iron is at least one size smaller than the earthen pipe. The objection that the pipes are not properly centered seems of little practical importance. It may be noted in passing that under ordinary conditions either the iron pipe would be larger or the tile smaller than those given in the inquiry.

Figure 2 shows an earthenware "increaser," with the connection made between pipes of the same diameter. However, as the earthen hub is much larger than a corresponding one of iron, there is always a danger that the unskilled workman will lay the pipes as indicated in Fig. 5, where the discharge will be partially obstructed by the projection of the earthen pipe above the line of flow, even if no burr of cement has been left inside the pipes. In addition to this, the ordinary earthenware hub is not deep enough to make a very strong cement joint with iron pipe. The "increaser " is, of course, simply another length of earthen pipe, which it might perhaps be inconvenient to set at a proper distance beyond the walls.

Figure 3 is a cast-iron "reducer" calked on the end of the 4-inch iron pipe and cemented into the hub of the 6 inch tile. Though more expensive in labor and material, there seems to be little advantage in this method, while there are the possible objections noted in Fig. 5, and also a greater difficulty, because of the reducer, in removing any cement which may be forced inside the pipe in making the joint.

In Fig. 4 a 4-inch iron "double hub " has been used, as suggested, giving a connection similar to that in Fig. 1, but at an increased expense. To do this, however, the so-called "standard" or lightweight cast-iron pipe must be used, as this fitting in the " extra-heavy" grade measures about 6¼ inches outside. The former grade of pipe has been very generally discarded in favor of the heavier and safer material which is now commonly required by the city plumbing regulations throughout the country. It is, however, quite possible to modify this method by calking a ring of 5-inch iron pipe on the end of the 4-inch so as to make the pipes more nearly concentric when introduced into the body of the tile. This would make a good connection with slightly more labor than No. 1.

All things considered, therefore, it would seem that the method shown in Fig. 1, while apparently less careful and accurate than the others, will under the ordinary conditions of careless workmanship and the like, give a thoroughly good and strong connection at a less expenditure of time and material than with any of the others suggested.]

Continue to: