Finals

Description

This section is from the book "A Treatise On Architecture And Building Construction Vol3: Stair Building, Ornamental Ironwork, Roofing, Sheet-Metal Work, Electric-Light Wiring And Bellwork", by The Colliery Engineer Co.. Also available from Amazon: A Treatise On Architecture And Building Construction.

Finals

73. Finials which are less than about 7 feet in height are usually built in the shop to conform with the drawings of the architect, and are taken to the building and erected in one piece. Larger finials, however, are usually set up in two or more pieces, according to their height, weight, and form. All the joints should be double seamed and soldered inside, in the same manner as cornice joints.

Finials having round members are built up from spun or pressed metal. Spun metal is preferable. Other forms are built together in different ways according to the shape of the members.

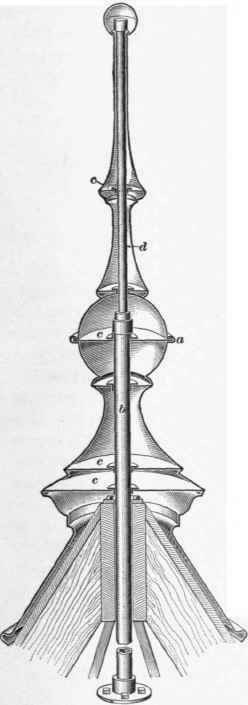

All finials must be securely supported to prevent them from sagging, and braced to prevent them from leaning out of plumb. The system of supporting and bracing required will depend upon the shape and size of the finial. In some finials a straight iron pipe alone will form a satisfactory support, while others must be provided with lookouts, like cornices, and often with braced framework. Fig. 58 shows a simple and efficient method of supporting a long, narrow finial on the peak of a conical roof. This finial is taken to the building in two pieces, and is joined together in position, with a lock seam around the ball. A 2-inch or 3-inch gal-vanized-iron pipe b is securely supported and braced to the framework of the roof. Horizontal partitions c, c are soldered to the inner surface of the finial and snugly fit the iron pipe. These form braces and keep the finial straight.

A few vertical gussets are soldered inside the ball to strengthen it vertically. A threaded pipe coupling is soldered inside the top ball so that this ball may be securely attached to the top of the pipe d.

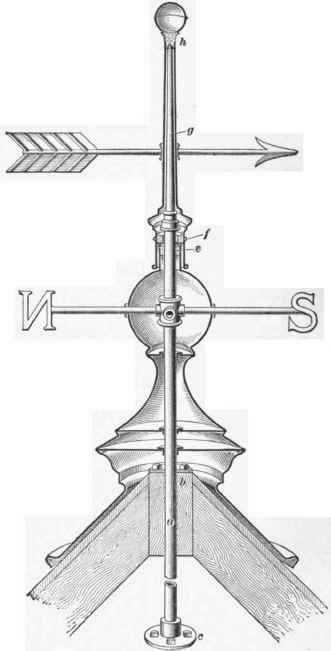

74. Weather vanes are a class of finials provided with a movable part which rotates on a vertical axis by the force of the wind. They are employed to show the direction in which the wind blows and consequently are provided with the letters N, S, E, W, located respectively north, south, east, and west of the axis of the finial. These letters are secured to the stationary part of the finial. An arrow, or some other form of indicator or pointer, is also employed in the construction; this is attached to the movable part of the finial. Fig. 59 is a vertical section through a simple weather vane. It is similar to the finial shown in Fig. 58 except that the top part is made to rotate. An iron pipe a, which rests on a solid footing, passes vertically through the apex of the roof. A collar at b and a cross-beam at c rigidly secure the pipe and keep it plumb. A special fitting called a double cross receives the arms which support the four letters already mentioned. These arms also reinforce the ball. The top of the stationary sheet-metal work is riveted to a brass ring e.

Fig. 58.

Fig. 59.

The bottom of the movable part of the vane is bolted to a brass ring f. These rings keep the copper in proper shape at the slip joint. The lower end of a tapered steel bar g is screwed into the reducing socket on top of the pipe. The top end of the rod is tapered off to a sharp pivot point, and works in a brass socket h. This rod must be free and clear from the copper shell around it, so that the arrow may swing around to face the wind with the least possible resistance. The movable section must be carefully balanced; it should be so sensitive that a man can move it with his breath. The ring f is located under the reducing socket, and prevents the movable section from being thrown off in a storm.

Continue to: