How To Make Railway Coupling Shackles

Description

This section is from the book "Cassell's Cyclopaedia Of Mechanics", by Paul N. Hasluck. Also available from Amazon: Cassell's Cyclopaedia Of Mechanics.

How To Make Railway Coupling Shackles

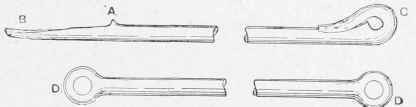

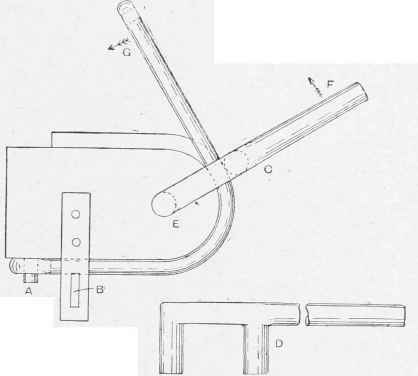

To get railway couplings to stand, the grain of the iron in the shackles must follow round the eyes. To accomplish this, the bar is first nicked with the fuller as shown at A (Fig. 1), and the end drawn out to form a scarf as at B, which is bent over as at C and welded, the eyes D being finished on the anvil with a pair of tools and a punch. The part between the two eyes is then heated and the bar placed with one of the eyes on the stud of a bending block A (Fig. 2), and fixed by means of a cotter at B. One of the horns of a bending tool C and D (Fig. 2) is placed in a hole E in the block, and the handle pulled rouud towards the arrow F, the bar following in the direction shown by the arrow G until the shackle is bent to the required shape. Fig. 2 shows the bending block in plan, and C and D are two views of the bending tool. The shackles are made of 1-in. to 1 1/2 -in. Lowmoor or Yorkshire iron, according to the class of vehicles on which they are used.

Fig. 1.

Fig. 2. Making Railway Coupling Shackles.

Continue to: