Compressed Oil Gas For Lighting Cars, Steamboats, And Buoys. Part 2

Description

This section is from "Scientific American Supplement Volumes 275, 286, 288, 299, 303, 312, 315, 324, 344 and 358". Also available from Amazon: Scientific American Reference Book.

Compressed Oil Gas For Lighting Cars, Steamboats, And Buoys. Part 2

Application To Cars

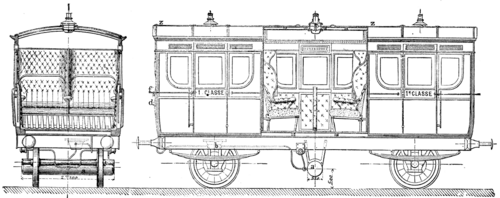

We show in the accompanying engravings the mode of installation that the inventor has finally adopted for railway purposes. Each car is furnished, perpendicularly to its length, with a reservoir, a, containing the supply of gas under a pressure of 6 or 7 atmospheres. The gas is introduced into this reservoir by means of a valve, which is put in communication with the mouths of supply pipes placed along a platform. The pipes are provided with a stopcock and their mouths are closed by a cap. To fill the car reservoir it is only necessary to connect the mouths of the supply pipes with the valves of the cars by means of rubber tubing--an operation which takes about one minute for each car.

LIGHTING OF RAIWAY CARS

When it is necessary to supply cars at certain points where there are no gas works, there is attached to the train a special car on which are placed two or three accumulators, which thus transport a supply of the compressed gas to distances that are often very far removed from the source of supply.

The reservoir of each car, containing a certain supply of gas, communicates with a regulator, b, the importance of which we scarcely need point out. This apparatus consists: (1) of a cast-iron cup, A, closed at the top by a membrane, B, which is impervious to gas; (2) of a rod, C, connected at one end with the membrane, and at the other with a lever, D; (3) of a regulating valve resting on the lever, and of a spring, E, which renders the internal mechanism independent of the motions of the car. The lever, acting for the opening and closing of the valve, serves to admit gas into the regulator through the aperture, F. This latter is so calculated as to allow the passage of a quantity of gas corresponding to a pressure of 16 millimeters. As soon as such a pressure is reached in the regulator, the membrane rises and acts on the lever, and the latter closes the valve. When the pressure diminishes, as a consequence of the consumption of gas, the spring, E, carries the lever to its initial position and another admission of gas takes place. Communication between the regulator and the lamps is effected by means of a pipe, z, of 7 millimeters diameter (provided with a cock, d, which permits of extinguishing all the lamps at once, and by special branches for each lamp. The lamps used differ little in external form from those at present employed. The body is of cast-iron; the cover, funnel, and chimney are of tin; and the burner is of steatite. The products of combustion are led outside through a flattened chimney, t, resting at o on the center of the reflector. The air enters through the cover of the lamp and reaches the interior through a series of apertures in the circumference of the cast-iron bell which supports the reflector. There is no communication whatever between the interior of the lamp and the interior of the car, and thus there is no danger of passengers being annoyed by the odor of gas. By means of a peculiar apparatus, f, the flame may be reduced to a minimum without being extinguished. This arrangement is at the disposition of the conductor or within reach of the passengers. For facilitating cleaning, the lamps are arranged so as to turn on a hinge-joint, m; so that, on removing the reflector, o, it is only necessary to raise the arm that carries the burner, r in order to clean the base, s, without any difficulty.

On several railways both the palace and postals cars are also heated by compressed oil gas; and lately an application has been made of the gas for supplying the headlights of locomotives (see figure), and for the signals placed at the rear of trains. But one of the most interesting applications of oil is that of

Continue to: