Cloth Stretching Machine

Description

This section is from "Scientific American Supplement". Also available from Amazon: Scientific American Reference Book.

Cloth Stretching Machine

As is well known, in the process of bleaching and dyeing, cotton cloths become considerably contracted in the width, in consequence of carrying on the operations when the cloth is in the form of a rope. The effect is that, together with the tension, although slight, and the drying, the weft partly shrinks and partly curls up, the latter, however, being scarcely observable to the naked eye. It may almost be said that as regards the width the shrinkage is due to a number of minute crumples because the cloth is easily streatched again by the fingers almost to its gray width. The main use of a stretching machine, therefore, is not so much to make the cloth more than it is as to bring it again to its normal or woven width after operations that tend to shrinkage have been performed upon it. The stretching operation, therefore, is especially useful to calico printers, as it enables them to obtain when desired a white margin of even width, the irregularities due to bleaching being corrected before printing.

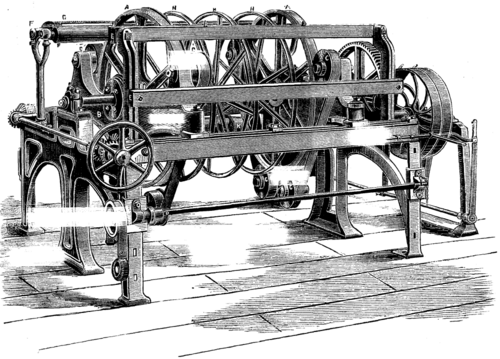

IMPROVED CLOTH STRETCHING MACHINE.

The machine now illustrated is one we have recently seen in operation in a Salford finishing works. It is an improved form of another stretching machine which had been turned out in considerable numbers by Mr. Archibald Edmeston, engineer, of Salford, who makes a specialty of calico printers' and finishers' machinery. The improvements consist mainly of a simplification of the working parts and thoroughly substantial construction of the machine. The principle adopted is a well-known one. The selvages of the cloth, or more strictly the two edges of the cloth, of a width of about two inches, are caused to pass over and at the same time are held by the rims of two diverging pulleys. The rims are further apart where the cloth leaves them than where they seize it, hence the stretching is gradually, certainly, and uniformly performed. The cloth is gripped by the pressure of an endless belt acting against the lower half of each pulley, the edges being held between them. In the engraving these stretching pulleys are indicated by the letters AA; the endless leather band passes over the pulleys, CC, of which there are a set of four provided for each stretching pulley.

The lower pair of pulleys in each case may be tightened up by a screw for the purpose of imparting the requisite tension to the bands. The stretching pulleys are mounted upon and driven by the same shaft, an ingenious but simple swiveling joint in their bosses enabling them to be set at any angle to the shaft and yet to revolve and be driven by it without throwing any undue strain upon the working parts. The piece, wound upon the ordinary batch shell, is placed upon the running-off center, D; it is led off over the rails, EE, and then downward to the nip of the bands and pulleys, AA. As explained, the selvages are here gripped between the bands and stretching pulleys, the rims of which are wider apart at the back than the front, and thus, in being conveyed underneath, the piece is suitably stretched. Leaving the grip at the back it passes over leading-off rollers, FF, and the scrimp or opening rail, G, and thence downward to the winding-on center, which cannot be seen. The winding-on center is driven by friction. As the batch fills it and tends to wind faster than the machine delivers the cloth, the driving slips.

In addition to a capability of being set at an angle to the shaft, the stretching pulleys, AA, may be slided upon, so as to separate or bring them closer together, to allow for the treatment of different widths of cloths. This adjustment is provided for by mounting the stretching pulleys, AA, and the band pulleys, CC, etc., on frames, BB, the ends of which rest, as shown, upon rails, at the back and front of the machine. The adjustment either for width of piece or for the angularity (extent of stretching) is easily made by the hand-wheel, L. By the bevel wheels shown, two cross screws having nuts connected to the ends of frames, BB, are actuated in such a way that as desired the space between the back and front of the pulleys may be closed in or opened out, or the two wheels, maintaining the same angularity, may be separated or closed in, either adjustment being expeditiously made. The wheels, HHH, are called center stretching wheels, the use of which is sometimes advantageous. They act in conjunction with a set of stretching pulleys, of which one, K, may be seen in illustration.

By a proper adjustment at the latter the piece is bent into a wavy form, where it passes between the whole of them, the effect of the corrugation being to loosen the center threads and to allow the piece to be more equally stretched with those near the selvages and more easily. This part of the machine may be used or not as required. The production, we observe, was about 120 yards per minute. The machine is solidly built and well fitted together, as was obvious to us from an inspection of some in course of construction at the maker's works. It is also claimed to be of considerable advantage to bleachers and finishers of white goods, on account of the uniformity of the stretching causing but small disturbance to the stiffening.--Textile Manufacturer.

Continue to: