Methods Of Distillation And Of Distilling Apparatus. Part 8

Description

This section is from the book "The Volatile Oils Vol1", by E. Gildemeister. Also available from Amazon: The Volatile Oils.

Methods Of Distillation And Of Distilling Apparatus. Part 8

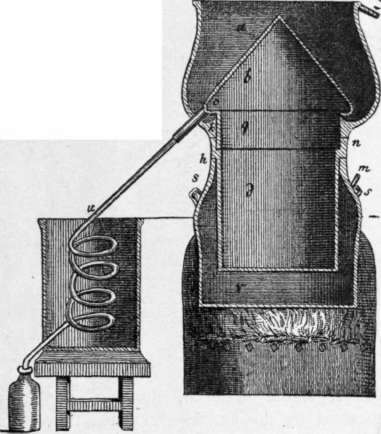

One of the better distilling apparatus used for the distillation of volatile oils in the 18. century consisted of a tin or copper body suspended in a water bath, and provided with a Mohren-kopf (fig. 15, p. 208), a Rosenhut (fig. 22, p. 211) and a spiral tube for condensation. An illustration (fig. 37) and description of this distilling apparatus was published in 1784 by Francois Demachy1) (born 1728, died 1803), director of the apothecary laboratories of the civic hospitals of Paris.

1) Les Euvres de M. Ambroise Pare, conseiller et premier chirurgien du roy. Paris 1575. Editio latina par Jean Haultin. Parisii 1582. p. 746.

2) Victorii Faventini Practicae magnae de morbis curandis ad tirones, tomi duo. Veneti 1562. Tom. 1, cap. 21, fol. 144.

3) See pp.48, 137, 182 and 183.

The copper kettle v serves as a waterbath, which can be turned by the handles s s and refilled with a fresh supply of waterthrough the side tube m. The tin still d rests with the upper ring n on the rim h of the kettle. The lower neck q of the head of the still b rests at n on the upper rim of the still. Around the lower edge of the head runs the trough c in which the distillate that has been condensed in the cone collects and passes with uncondensed vapors through the tube c - u into the spiral condenser.

The Mohrenkopf a, serving as a cooler for the Rosenhut b, is soldered to the neck k of the condensing cone. The water in the cooler warmed during the process of distillation, runs off through the upper tube e as fast as cold water is added.

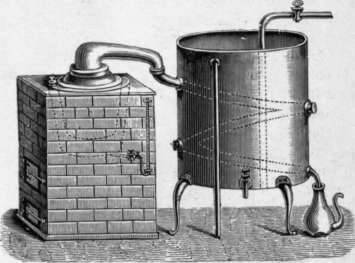

Since the beginning of the 19. century attemps have been made to simplify and to improve the construction of the distilling apparatus, more especially of the cooler, also to prevent the burning of the plants on the bottom of the still caused by the application of direct heat. Such improvements were made especially by Joh. Gottfr. Dingier,1) apothecary in Augsburg, during the years 1815 - 1820, by Smithson Tennant2) in 1815 and by Henry Tritton8) in 1818, both of England. The latter attempted to carry on the distillation at a lower temperature by connecting the apparatus with an air pump. The distilling apparatus more commonly in use at that time for the distillation of volatile oils was the one shown in the accompanying cut (fig. 38).

Fig. 37.

1) J. F. Demachy, L'art du destillateur des eaux fortes. Paris 1773. - The German edition bears the following title: Herrn Demachy's Laborant im Grossen, oder die Kunst, die chemischen Produkte fabrikmassig zu ver-fertigen. In 3 The Hen. Mit Dr. Struves Anmerkungen und einem Anhange einiger Abhandlungen des Apothekers Wiegleb. Translated from the French and supplied with additions by Samuel Hahnemann, der Arzneikunde Doctor und Physicus des Amts Gommern. 3 Vols. Leipzig 1784. Vol. 1, pp. 192 - 198 and plate 2, Fig. 1.

Steam distillation was recommended in 1826 by H. Zeise4) and especially for volatile oils by van Dijk in Utrecht,5) who thereby materially aided in its introduction. He demonstrated that "the volatile oils which were obtained by steam alone from the vegetable material, distinguished themselves from those obtained by distillation over open fire, by a lighter color and purer odor. Clove oil distilled with steam is nearly colorless, cinnamon oil light straw yellow and orange peel oil completely colorless."6)

Fig. 38.

1) Trommsdorff's Journ. der Pharm. 11,1. (1803), 241; also Buchner's Repert. fur die Pharm. 3 (1817), 137; and 6 (1819), 142.

2) Philosoph. Transact, of the Royal Soc. of London. 1815. - Repertory of Arts. London. Sept. 1815.

3) Annals of Philosophy. June 1818. - Buchner's Repert. fur die Pharm. 6 (1819), 98.

4) H. Zeise, Beitrage zur Nutzanwendung der Wasserdampfe. Pamphlet. Altona 1826. - Arch, der Pharm. 16 (1828), 69.

5) Buchner's Repert. fur die Pharm. 29 (1828), 94. 6) Ibidem 29 (1828), 110.

The first steam distillation on a larger scale in a pharmaceutical laboratory appears to have been that in the old Apothecary's Hall in London.1)

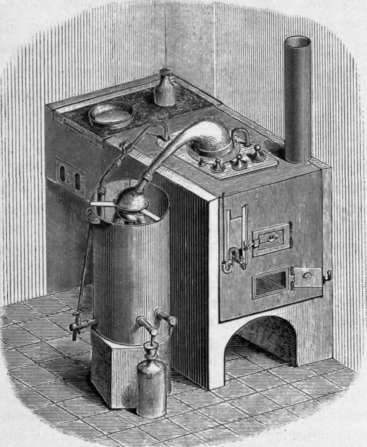

In Germany steam distillation for the preparation of volatile oils in apothecary laboratories was also made possible by the introduction of a steam distilling apparatus, constructed about the year 1826 by Johann Beindorff,2) mechanic and tin founder in Frankfurt-on-the-Main (fig. 39). With this apparatus, soon perfected in many ways, the distillation of volatile oils with steam under pressure was possible. The condensing arrangement also had the advantage over the spiral tube by being made up of separate parts, and thus allowing it to be readily cleaned even on the inside.

Fig. 39.

1) Buchner's Repert. fur die Pharm. 29 (1828), pp. 112 and 113. 2) Geiger's Magazin fur Pharmazie etc. 11 (1829), 174 and 291. - Buch-ner's Repert. fur die Pharm. 33 (1830), 436.

For the preparation of volatile oils on a small scale, the arrangements based on the original steam distilling apparatus of Beindorff remained, until the industry conducted on a large scale became dominant also in this field and prepared products of a quality and at prices with which the preparation on a small scale could not compete.

Of the arrangements used for a long time for the separation and removal of the oils from the water, the Florentine flask in various forms and sizes has shown its utility and has been in continual use. It probably came into use in the middle ages. A method of separation of oil and water, which in its principles corresponds to those of the Florentine flask, was apparently described for the first time by Porta1) in the latter half of the 16. century.

"When oils are extracted from plants, those substances which with the water pass over into the receiver must be separated carefully, in order that the oil, which contains on excess of phlegm, may not be weakened. Hence the oil must be rectified in order that it may retain its full strength. This is accomplished by distillation and separation. For this purpose the first distillates are mixed, poured into a retort placed into a water bath (in balneo Marias) and slowly distilled over. The pure oil will float on the surface of the aqueous distillate. The separation of the oil from the water demands painstaking labor. For this purpose, however, ingenious vessels have been devised which admit of the ready separation of water and phlegm from the oil. The glass vessel serving this purpose is open at the top and widens out funnel-like toward the bottom. The water, phlegm and oil are transferred slowly, drop by drop, into this flask, whereby the oil rises to the surface. A lateral tubular opening is closed with the finger. By effecting a partial opening the lower layer of water is allowed to flow out, whereas the oil collects above the opening closed by the finger. Thus the oil is separated from the water that has been allowed to flow out. Finally the oil is transferred to another container.

Continue to: