Window Screen

Description

This section is from the book "Manual Training For The Rural Schools", by Louis M. Roehl. Also available from Amazon: Manual Training For The Rural Schools.

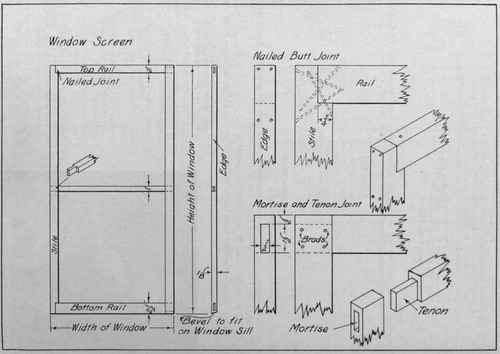

Window Screen

Material Required For Each Window

Lumber: 1 piece white pine or cypress 1 1/8x2 1/2 inches by width of window for bottom rail. 1 piece white pine 1 1/8 x2 inches by width of window plus twice the length of window for top rails and stiles.

1 piece white pine 1 1/8x 1 inch by width of window for middle rail. Enough screen moulding to cover edges of screen and middle rail.

Hardware: Twenty lOd casing nails, if nailed joint is used; 1 package No. 16 brads if mortise and tenon joint is used and for nailing moulding; package of carpet tacks for screen; wire fly screen; paint.

The finished dimensions are not given here as they must be obtained by measuring the window where the screen is to fit.

The mortise and tenon joint is the stronger and better way of joining the screen at the corners, yet a nailed joint holds the members firmly in place if the nails are well placed at an angle as shown in the drawing. The screen need lap only far enough on the sides and ends to be securely nailed. It should not project outside of the moulding which is placed on the inside edge of the sides and ends and across the middle rail.

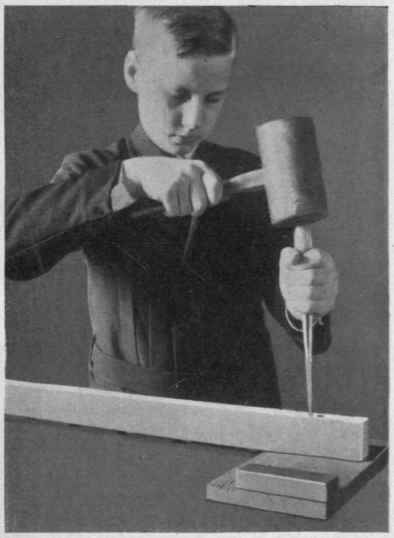

Fig. 19. Position of Chisel and Mallet for Mortising.

The painting should be done carefully so as to prevent moisture from getting into the joints.

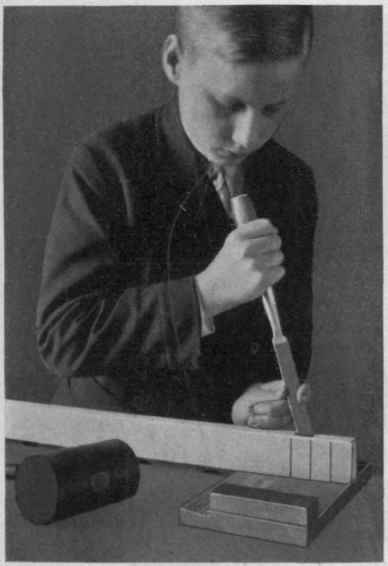

Fig. 20. Method for Holding Chisel in Mortising.

Continue to: