Drain-Pipes. Part 5

Description

This section is from the book "The Principles And Practice Of Modern House-Construction", by G. Lister Sutcliffe. Also available from Amazon: How Your House Works: A Visual Guide to Understanding & Maintaining Your Home.

Drain-Pipes. Part 5

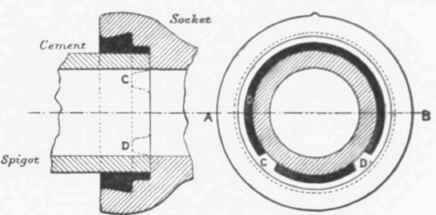

Fig. 319 shows the "Loco" self-centring joint. It will be seen that on the socket are two lugs, c and D, on which the spigot rests, so as to bring the inverts true at the joints. The lugs prevent the insertion of tarred gaskin the whole way around the spigot, and as there is no provision made, as in Hassall's joint, for preventing the cement from coming up through the joint, a badger must always be drawn through the pipe for the purpose of wiping off the projecting cement.

It will be seen that there are many difficulties to be overcome in forming a perfect cement joint. It is not surprising, therefore, that considerable attention has been given to this matter; the patents for drain-pipe joints that have beta taken out within recent years have been very numerous indeed, but many of these, although displaying great ingenuity, have failed to meet with practical success. Some of them have been found wanting in important particulars; and it is not necessary to do more than just mention them, such as those designed to afford arrangements to facilitate inspection, including half-socket pipes, chain and saddles, access-openings, butt-joint pipes with loose collars, ground joints, tongue-and-groove joints; other patents are for joints made by compressing

Fig. 318 - Drain-pipe Joint made with Gasket and cement.

Fig. 319 - The "Loco" Self centering Joint.

Sectional Plan on line AB

End Elevation flexible materials in the socket, arrangements to secure firm beddingof pipes, and arrangements to secure truth of invert. The special joints most generally used to- day may be classed under three heads: - first, joints based on Stanford's principle; second, spigot-and-socket joints with provision for pouring-in liquid cement: third, screw joints.

Stanford's joint is the oldest of all special joints, and is still in the field. It was patented in 1873 by Mr. W. H. C. Stanford, and is shown in Fig. 320. On the socket is cast a ring of asphalt, and a similar collar is cast on the spigot, the latter being tapered in order to admit of a small amount of adjustment in laying the pipes, and also a slight settlement without injury. In laying the pipes, both the ring and the collar require greasing so as to get the joint to fit more readily, and to prevent .stripping the composition when the pipe is being adjusted to its position. As the patent has run out, any person can make this joint on ordinary pipes, the composition being formed of one part of clean sharp sand, one part of boiled tar. and one part and a half of sulphur. Messrs, Doulton for some time have had a joint based very much on the same lines, which has culminated in the production of the joint known as "the self-adjusting joint", and which is shown in Fig. 321. It is formed by the contact of two bands of composition cast on the spigot of one pipe and in the socket of the other pipe; that on the spigot is of a convex form, and therefore admits of deflection on the same principle as a ball-and-socket joint; the lining on the socket is cylindrical. - that is, of the same diameter throughout its depth, and partial withdrawal of the spigot therefore does not impair the joint. It is free from complication and efficient, as very little depends upon the workman, the work to l>e done in the trench being reduced to a minimum. The pipes are supplied with the joint attached, and the spigot of one has only to be inserted into the socket of another to make the joint complete.

Fig. 320- Stanfords Drain- pipe Joint.

Fig. 321 - Doulton's "Self-adjusting" Drain pipe Joint.

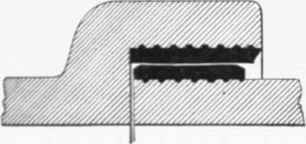

The single-lined pipes of Hassall's patent joint are shown in fig, 322. It is somewhat similar to Stanford's, but the sockets are much deeper, In making this joint, the ring and collar arc first coated with a specially-prepared plastic cement (which is sent out with the pipe), and then the pipes are pushed home; only the joint is set Hush, plastic cement filling up the interstices between the spigot and the abutting edge of the socket; the joint is then completed by pointing with Portland-cement mortar.

Fig. 322 - Hassel's Single-lined Drain pipe Joint a. with ordinary socket ; B, with deep socket.

There arc obviously many advantages in using special forms of pipe-joint There is a certainty of always getting a perfectly Round, straight, well-glazed, and truly cylindrical pipe, as none but the best pipes are selected for the purpose of jointing in a special form, and while the labour involved in this process of selection must necessarily be paid for, the extra cost is certainly recouped by the excellence of the pipes. There is also the facility in making the joints, and the rapidity with which they can be completed as compared with caulked joints.

Continue to: