Materials

Description

This section is from the book "The Principles And Practice Of Modern House-Construction", by G. Lister Sutcliffe. Also available from Amazon: How Your House Works: A Visual Guide to Understanding & Maintaining Your Home.

Materials

For the matrix of concrete for external walls Portland cement is by far the most satisfactory material. The best cement only must be used - finely ground, strong, and sound.1 The sand must be sharp, free from saline, clayey, and organic matter, and not too fine; and the aggregate must be hard, impervious, angular, clean, and not too uniform in size. As the absorption and perviousness of concrete depend largely on the nature of the aggregate, soft bricks and coarse-grained porous stone must not be used. If good results are required, not only must the cement be of the best, but also the sand and broken stone, and the materials must be separately measured, and thoroughly mixed together with a proper quantity of clean water. Constant intelligent supervision is also necessary.

The concrete should contain sufficient cement to fill the interstices in the sand, and the combined cement and sand (i.e. the mortar) should thoroughly fill the voids in the aggregate. To attain this object, the ingredients should be used in the following proportions - 1 part of cement + l½ parts of sand + 3 or 4 parts of suitable aggregate. Poorer concrete than this is often used in walls, but it is not wise to do so, at any rate in expose I situations, unless the concrete is faced with brick or stucco, or some other material. Concrete used in the construction of walls in London is specified by the County Council to be composed of "Portland cement and of clean Thames or pit ballast, or gravel, or broken brick or stone, or furnace clinkers, with clean sand, in the-following proportions, viz. one part of Portland cement, two parts of clean sand, and three parts of the coarse material, which is to be broken up sufficiently small to pass through a two-inch ring".

Although good concrete is undoubtedly stronger than an ordinary brick wall of the same thickness, the London County Council requires "the thicknesses of concrete walls to be equal at the least to the thicknesses for walls to be constructed of brickwork". A further regulation is that "such portions of concrete party-walls and chimney-stacks as are carried above the roofs of buildings [must] be rendered externally with Portland cement".

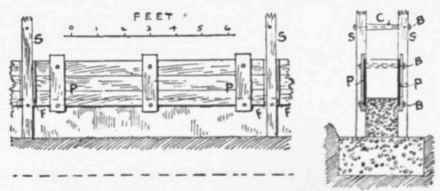

Figs. 42 and 43, reproduced from the writer's work on Concrete, give an elevation and section of a simple building-frame for concrete walls; ss are the standards bolted together in pairs at distances of from 6 to 12 feet, p p are the "shutters" or movable panels of wood, also bolted together in pairs by means of the bolts bb, which pass through wood cores or distance pieces c, these being tapered slightly in order to facilitate removal when the concrete has set; the shutters are kept in position by wood fillets, f f, nailed to the standards. Many different kinds of building-frames have been patented, but the simple arrangement illustrated will suffice for ordinary purposes.

Fig, 42 and 43. - Elevation and Section of Building-frame for Concrete Walls.

1 See pages 73 and 74.

Inferior concrete must be faced outside with Portland-cement stucco, which may be "divided into ashlar" by sunk lines (a bad plan, as the sinkings retain moisture, and lead sometimes to the flaking of the surface-cont), or may be finished in colour with oil paint or duresco.

Concrete blocks are now used to a considerable extent, not only for sea-walls and other engineering works, but also in buildings. For the latter purpose, however, the blocks are often known as "artificial stone", and are used chiefly in the form of " dressings", such as door and window heads, window-sills, moulded string courses and cornices, panels, finials, and other ornamental work; they are made in various colours, but chiefly red and buff. When properly made of good materials, concrete blocks are sound and durable, but their appearance is not as a rule very pleasing. They are laid like ordinary masonry.

Continue to: