Timbering To Excavations. Continued

Description

This section is from the book "Modern Buildings, Their Planning, Construction And Equipment Vol1", by G. A. T. Middleton. Also available from Amazon: Modern Buildings.

Timbering To Excavations. Continued

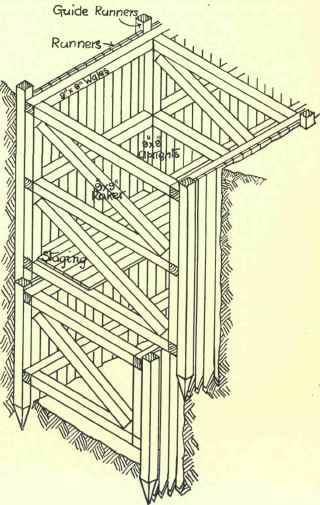

Fig. 77.

Excavations To Pier Shafts

When excavating for a shaft a hole is excavated as deep as possible without the earth falling in. Vertical sheeting from 9 by 1 inch to 9 by 2 1/2 inches, according to the nature of the soil, is temporally strutted against the faces of the excavation

Walings running right across the excavation are held in position against two opposite sides and strutted by means of walings forced between them against the other two sides. Cleats are fixed to the ends of the first pair of walings, so as to prevent the other pair of walings from being forced out of position.

Another layer of earth is now excavated and a second tier of sheeting is placed with the upper end overlapping the lower end of the first tier, and a second row of walings is inserted to secure both tiers together, and uprights are placed tightly between the walings at the corners of the shaft.

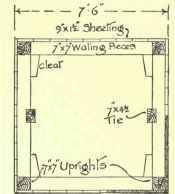

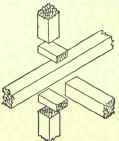

When the shaft is of considerable depth the timbering is prevented from sliding down the shaft by making one pair of walings to project well beyond the shaft at the top and to rest upon the surface of the ground, as in Fig. 78, a timber being notched over all the walings to act as a tie. If the shaft be very deep a pair of the bottom walings is buried in the side of the cutting, being formed in two pieces with a keyed and scarfed joint in the middle similar to A (Fig. 251 and Plate VI.).

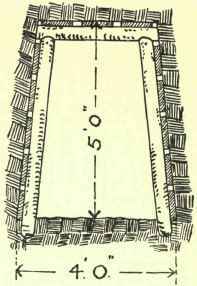

Excavations to shafts should never be less than 4 feet square, as a man cannot work in a less space than this.

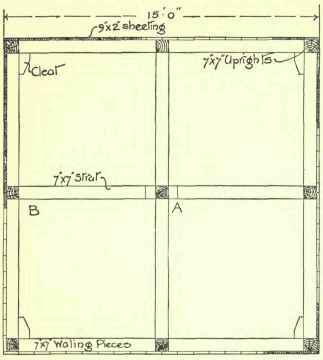

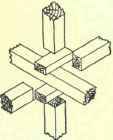

The above system of timbering may be used for shafts up to about 10 feet square; but if shafts larger than this have to be sunk, the system shown in Fig. 79 must be used. In this case the sheeting and waling pieces are inserted as explained with reference to Fig. 78, and two struts are placed at right angles to one another across the centre of the shaft, one of these struts being in one piece and the other in two pieces, the ends of the latter being supported at one end by small pieces of timber placed between the side walings and the uprights, and at the other end by similar small pieces of timber placed between the central struts and uprights, as shown by the disjointed details in Fig. 79.

Plan.

Fig. 78.

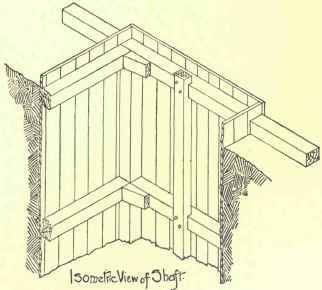

Excavating Tunnels

It is sometimes far more economical to cut tunnels for such work as drain laying than to excavate very deep trenches. These tunnels may be of any size; but they are usually just large enough to enable one man to work, i.e. not less than 4 feet square. The method of excavating' a tunnel is as follows: If the soil is good, sections from 2 to 3 feet long are dug out, poling boards are then temporarily-fixed round the opening, a head-piece held in position, and finally strutted by means of upright struts, as shown in Fig. 80, these latter being kept in position by spiking them to the head or by having cleats fixed to the head. Another length of tunnel is excavated and another series of poling pieces is inserted with the ends overlapping the first series of poling pieces, and another frame composed of head and struts is fixed against these overlapping ends.

Detail of A.

Fig. 79. Detaill of B.

Failure Of Timbering

Serious accidents happen from time to time owing to the failure of timbering in excavations. This failure is usually due to one of the following two reasons: -

Fig. 80.

1. The struts fail under the pressure of the earth; or,

2. The struts drop out by the shrinkage of the soil.

1. This is perhaps the most frequent cause of failure, as the pressure from soils is often underestimated, particularly that of clay soils, which sometimes swell with enormous force when exposed to the atmosphere. When excavations are made in soft soil in the vicinity of heavy buildings the lateral pressure of the soil is usually very great.

To prevent such failures the timber should be of ample size, and should be examined before being inserted in the excavations, and all faulty pieces rejected; while in very deep trenches the struts in the lower parts of the trenches should be larger than those near the surface.

2. To prevent struts dropping out of place they should be examined from time to time and tightened when necessary; but a better plan is to spike them to the walings or to fix cleats underneath them. The struts supporting stages should always be spiked or fixed in some way, as they are very likely to become loosened by the weight and motion of the excavator, who stands upon them to work.

Continue to: