140. Compressing Steel

Description

This section is from the book "An Elementary Outline Of Mechanical Processes", by G. W. Danforth. Also available from Amazon: An elementary outline of mechanical processes.

140. Compressing Steel

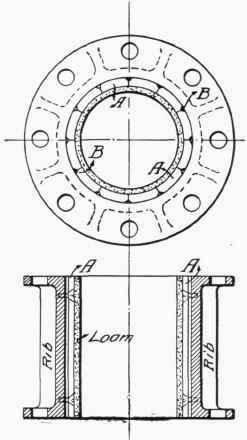

The method of compressing steel is briefly as follows: On a specially built car not unlike an ingot car is placed a large cylindrical mould built up of very heavy cast-iron sections, one of which is shown in Fig. 36, bolted by their end flanges to each other and to a cast-iron bottom. For very heavy pressures, however, a steel tube forms the length of the mould, and this is fortified by a series of short steel tubes slipped over the long tube, as shown in Fig. 37. The inside diameter of the mould is about 42 inches and its depth about 16 feet. The inside of the mould is lined with cast-iron bars as shown at A A in Fig. 36, plastered over with about 1/2 inch of loam, a refractory mixture of sand and clay. Two edges of each of the bars are champfered to form vertical openings, as at BB, by which air in the loam and some gases in the metal may escape.

Fig. 36. - Mould Section for Whitworth Press.

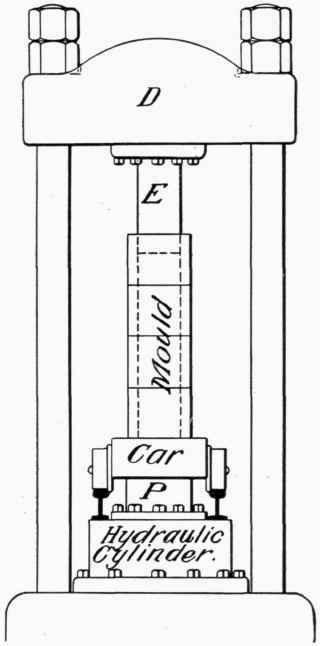

The inside of the mould, having been thoroughly dried and heated very hot by a charcoal or oil fire, is poured nearly full of steel tapped from the furnace. The car is then run under a hydraulic press (Fig. 37), the upper head D of which is stationary and carries a heavy plug E which will exactly fill the upper end of the open mould. The car having been correctly placed, the hydraulic ram P lifts the car body and the mould until the plug E is pressed to the intensity desired against the surface of the molten steel. A film of metal squeezes up between E and the mould lining, but it soon solidifies and prevents the escape of more metal. The pressure is held on the steel for about four hours, until the ingot has solidified. Some gas and slag are pressed out at the top and also from the surface of the metal in contact with the mould, but pressure cannot squeeze anything from the interior of the molten mass. However, it reduces the size of the bubbles and compresses the slag particles densely together in the interior of the mass. An ingot fifteen feet long is decreased about 12 or 14 inches in length by this pressure. From 20 to 30% is cut from the top of this ingot, after it is cold, as a discard.

Fig. 37. - Whitworth Press for Molten Steel.

Steel of this kind is used for guns, armor, and marine-engine shafting. Its uses are not extensive because the expensive equipment for making it add to its cost and thus prevents a great demand for this steel in preference to other grades. The Whitworth process is not applied to Bessemer steel because open-hearth steel has the preference as a better product to begin with.

Continue to: