85. Producer Gas

Description

This section is from the book "An Elementary Outline Of Mechanical Processes", by G. W. Danforth. Also available from Amazon: An elementary outline of mechanical processes.

85. Producer Gas

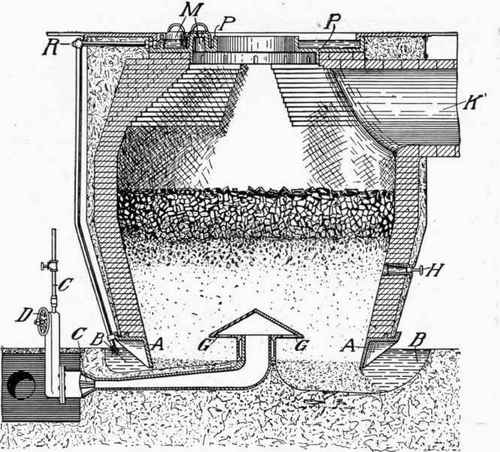

Producer Gas is made as follows, referring to the gas producer in Fig. 13. A shell of steel plates, lined with fire-bricks, rests on a cast-iron ring A, which in turn is supported by lugs resting on the edge of a basin B. This basin, which is a depression in the concrete floor, is kept filled with water. The interior of the producer contains fuel in various stages of burning, varying from water-soaked ashes in the basin at the bottom to a continuously supplied layer of fresh fuel at the top.

By means of a central tuyere with a mushroom head G, steam from the pipe and nozzle marked C, and air drawn through the damper D, are blown into and distributed through the fuel, entering the hot ashes at G, and rising through the zone of incandescent fuel. When the air and vapor become sufficiently heated, the oxygen of the air combines with the carbon of the fuel. The tendency of this combustion is to form Co2, but the relatively small quantity of oxygen carried in by the air in presence of a large amount of incandescent carbon soon reduces the Co2 to CO. The heat produced by combustion is intense enough to decompose the water vapor, the oxygen combining with the carbon of the fuel and the hydrogen rising uncombined. The gases resulting from this partial combustion of fuel and the hydrogen resulting from the decomposing of steam rise into the space above the fuel and pass away through the outlet K into "scrubbers" or cleaning compartments, thence into the storage tanks ready for use.

Fig. 13. - Gas Producer.

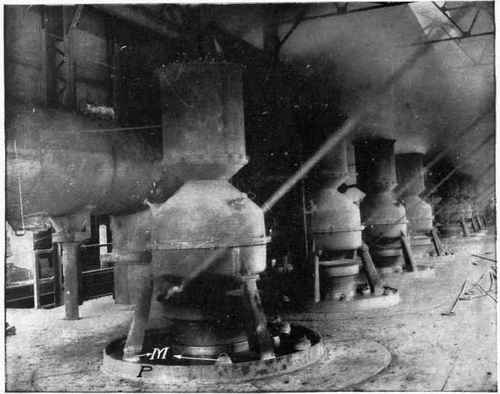

The central opening at the top is the seating for an automatic feeder (not shown in the sketch) regulated to drop fuel into the producer continuously at the rate needed. Fig. 14 shows a row of these feeders, surmounted by coal hoppers, along a working floor over the producers. The brick-work forming the body of the furnace, as shown in Fig. 13, is closed at the top by a cast-iron pan P, which holds water for keeping the top cool. This water is received from a small pipe and flows from the pan into the ash basin through a small pipe R in the quantity needed to keep the basin B about full. It serves also as a water seal both in pan and basin to prevent the escape of gas from the producer. The fuel is poked through the holes II on the side and through the water-sealed holes M on top if it becomes clogged. The small covers for the watersealed holes on the top are shown at the floor level in Fig. 14. Ashes are removed from the basin at the bottom of the producer.

Fig. 14. - Automatic Feeders for Gas Producers.

The gas product passing out at K consists essentially of (1) CO, from partial combustion of the fuel, (2) hydrogen from the decomposed steam, (3) and a small quantity of hydrocarbon gas distilled from the coal as it heats up before beginning to burn; these are the combustible gases and should be about 50% of the whole volume of gas produced for maximum efficiency of a producer. The remainder of the mixture consists of (4) a slight amount of Co2 from complete burning of the fuel, and (5) considerable nitrogen unavoidably entering as a constituent of air.

The relative amounts of air and steam blown in must be carefully regulated. With no steam, the combustion would need much more air, resulting in larger proportions of nitrogen and Co2, as well as in too intense a heat in the producer. Steam is advantageous because it (1) displaces nitrogen; (2) absorbs heat in its decomposition, thereby keeping down the temperature of the producer; (3) supplies oxygen for combustion, and (4) hydrogen for enriching the gas product. Too much steam checks combustion by displacing air and by lowering the temperature of the furnace below that required for burning the fuel.

Producer fuel for metallurgical work usually consists of the ordinary grades of bituminous coal, including lignite. Usually the cheapest grade of coal in the locality where the producer is installed is suitable provided (1) it does not contain an excessive amount of sulphur nor (2) a large per cent of ash which forms pasty clinkers. The richest gas is made from gas coals because of the volatile hydrocarbons they give to the producer product. The fuel for a producer should be in small lumps, because coal which is wholly "slack" or very fine will resist the passage of air and steam. There are several varieties of gas producers but all embody the same principle.

Continue to: